Method for producing glass film

A manufacturing method and glass film technology, applied in glass manufacturing equipment, glass forming, glass forming, etc., can solve problems such as difficult and high-precision glass film cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

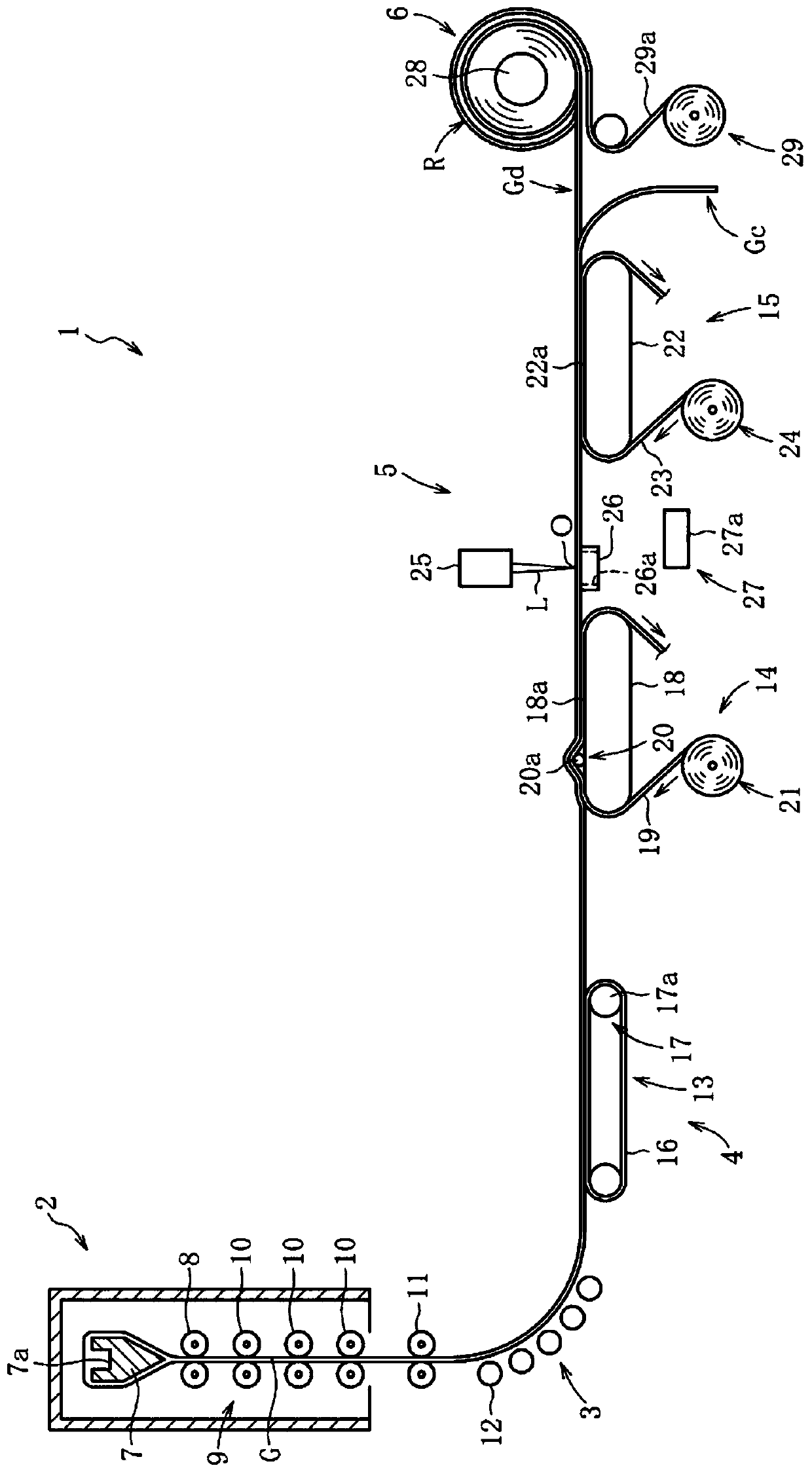

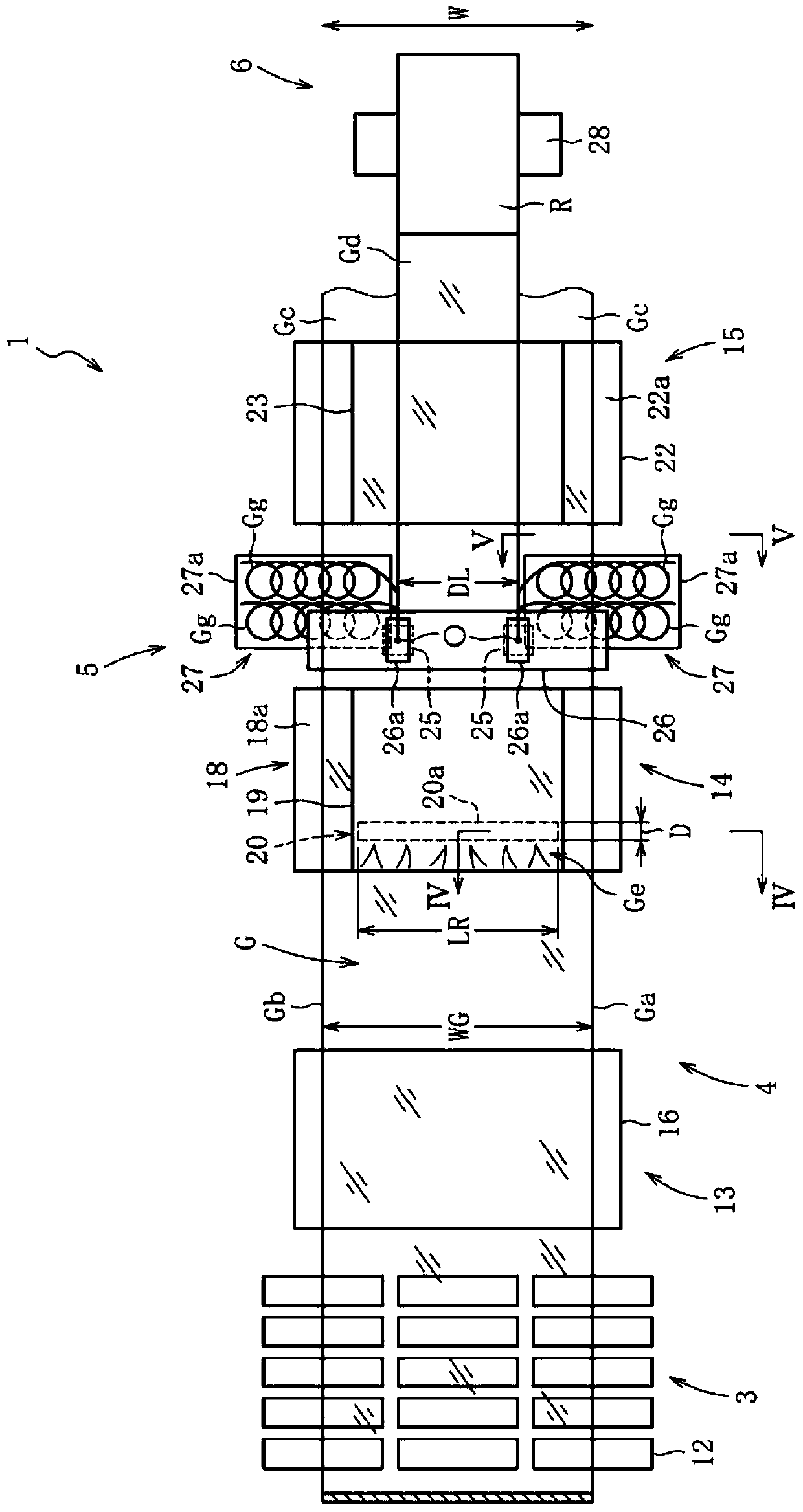

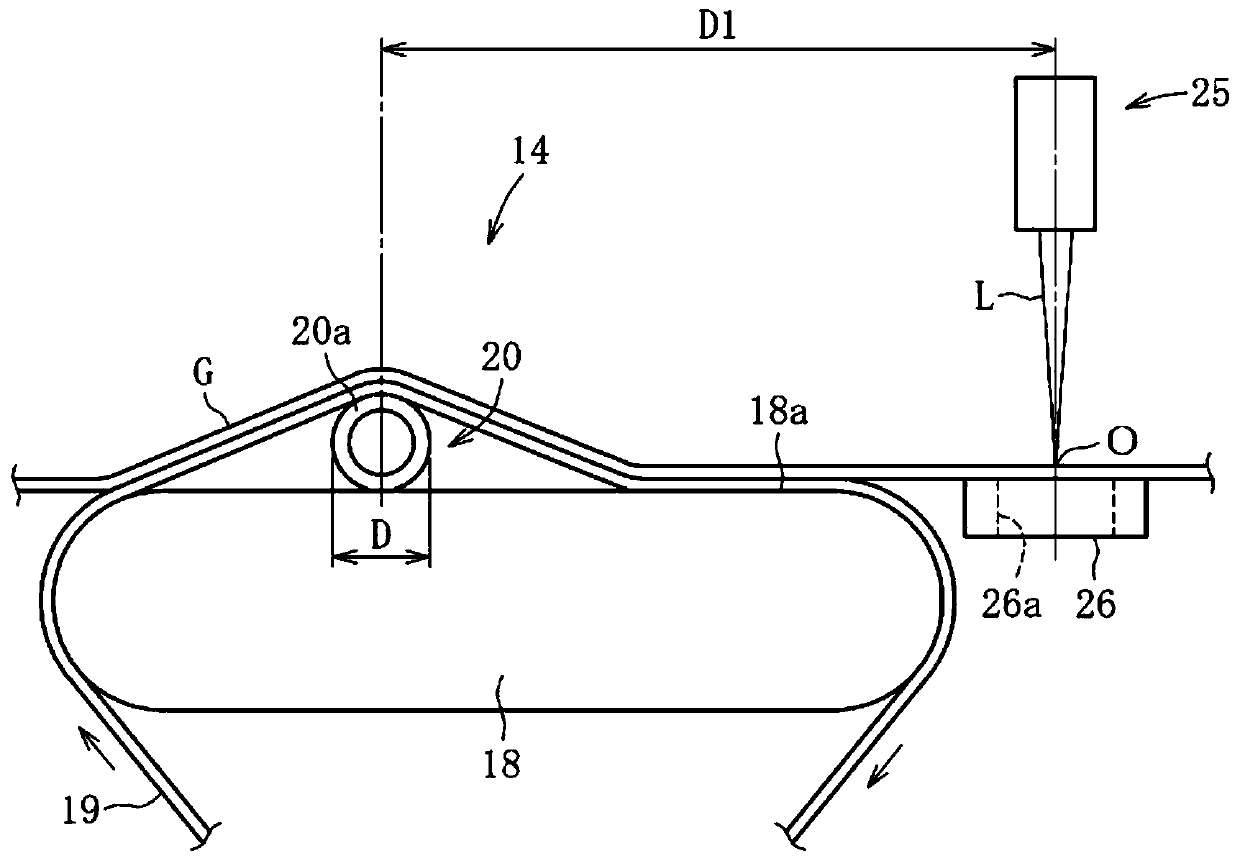

[0045] Embodiments for implementing the present invention will be described below with reference to the drawings. figure 1 6 shows the first embodiment of the production apparatus for carrying out the production method of the glass film of the present invention.

[0046] figure 1 It is a schematic side view schematically showing the overall structure of a glass film manufacturing apparatus. Such as figure 1 As shown, the manufacturing device 1 is provided with: a forming part 2, which shapes the glass film G; a direction changing part 3, which changes the traveling direction of the glass film G from vertically downward to horizontally; The glass film G is transported in the lateral direction; the cutting unit 5 cuts the widthwise ends Ga, Gb of the glass film G into non-product parts Gc while being transported in the lateral direction by the transverse transporting unit 4; The glass roll R is comprised by winding up the product part Gd obtained by cutting and removing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap