Adhesive tape cutting method and adhesive tape cutting apparatus

A technology for cutting off devices, adhesive tapes, used in transportation and packaging, metal processing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

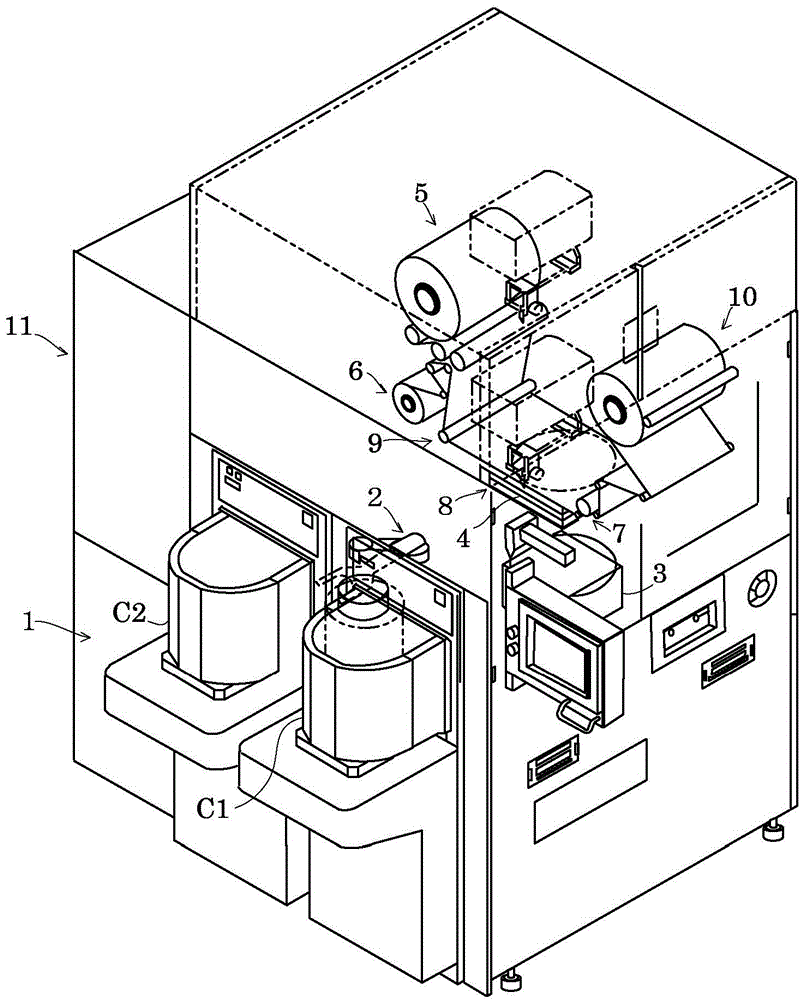

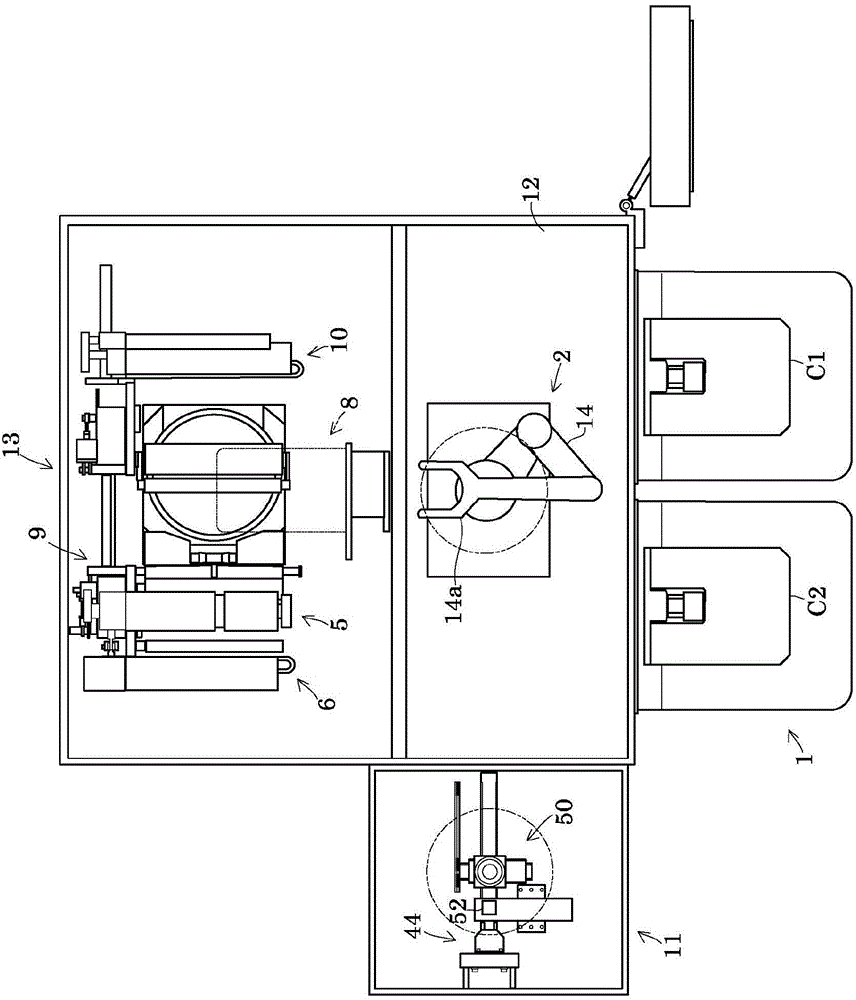

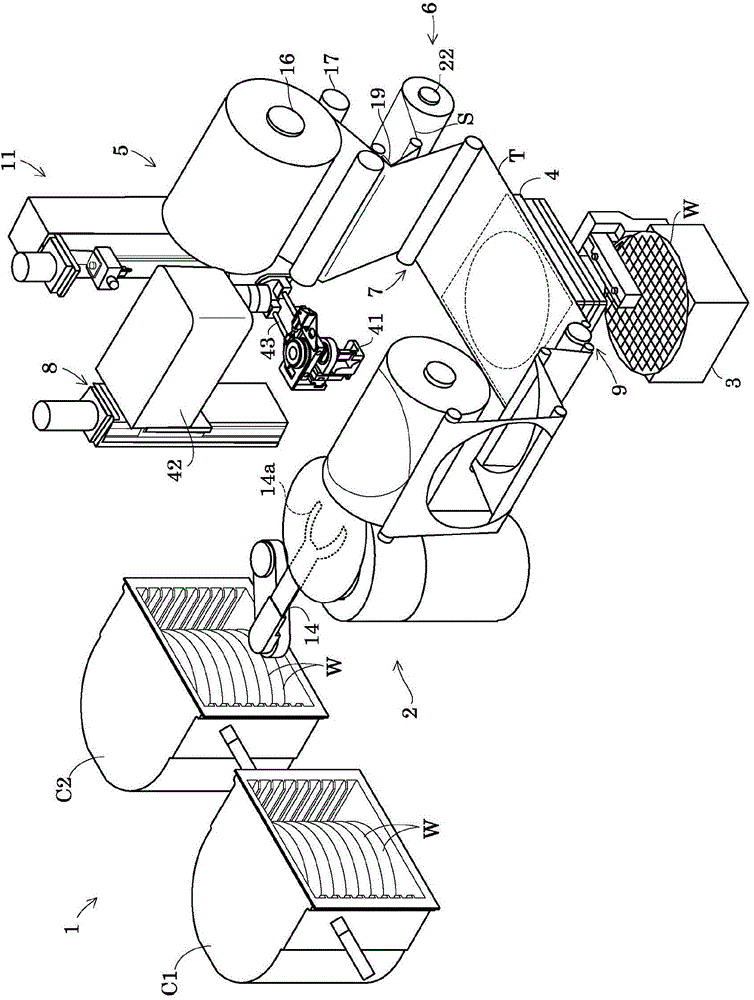

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in this embodiment, an apparatus for affixing an adhesive tape for surface protection to a semiconductor wafer (hereinafter, simply referred to as a “wafer”) will be described as an example.

[0046] figure 1 It is a perspective view showing the overall structure of the adhesive tape sticking device, figure 2is a top view of the adhesive tape sticking device, image 3 It is a perspective view showing the main part of the adhesive tape sticking device.

[0047] Such as figure 1 and figure 2 As shown, the adhesive tape sticking device includes a wafer supply / recovery unit 1, a wafer transport mechanism 2, an alignment table 3, a holding table 4, a tape supply unit 5, a separator recovery unit 6, a sticking unit 7, a first cutting Mechanism 8, peeling unit 9, tape recovery unit 10, second cutting mechanism 11, etc. Here, the wafer supply / recovery unit 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com