Cut-off device

A technology of cutting device and mounting surface, applied in glass cutting device, fine working device, stone processing equipment, etc., can solve problems such as troublesome work, large deviation, deviation of the surface parallelism of the pressing blade substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

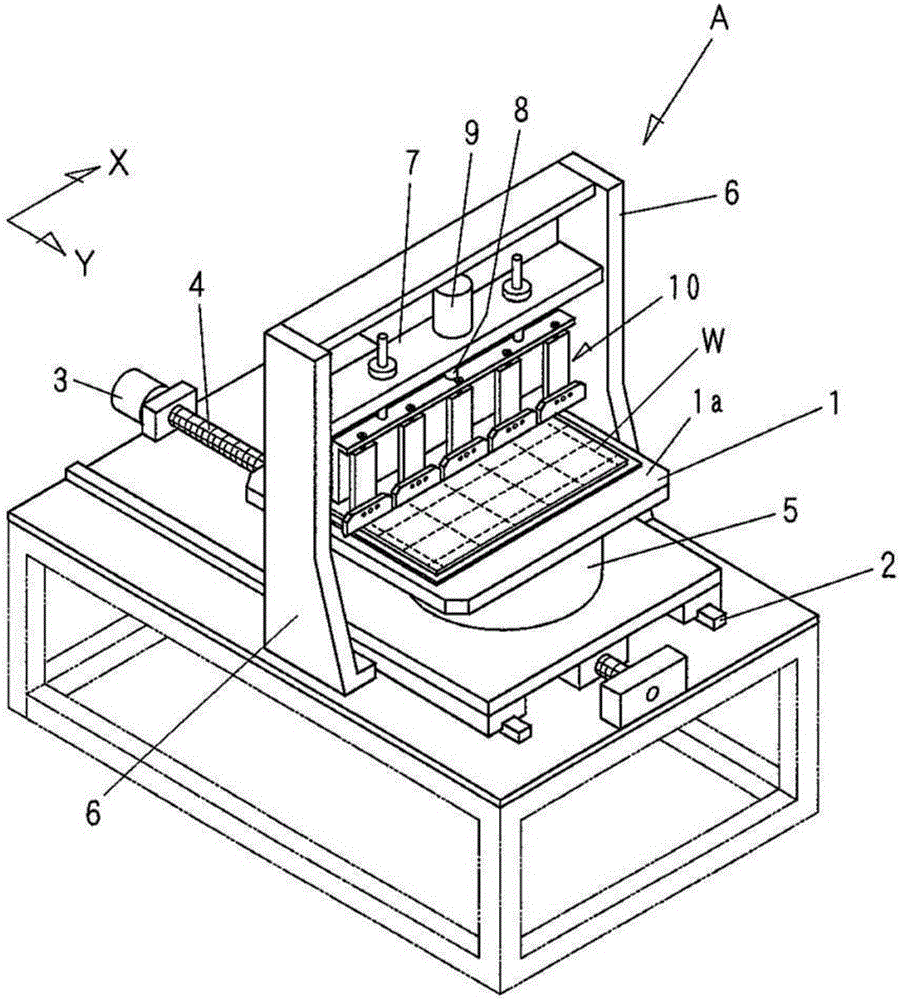

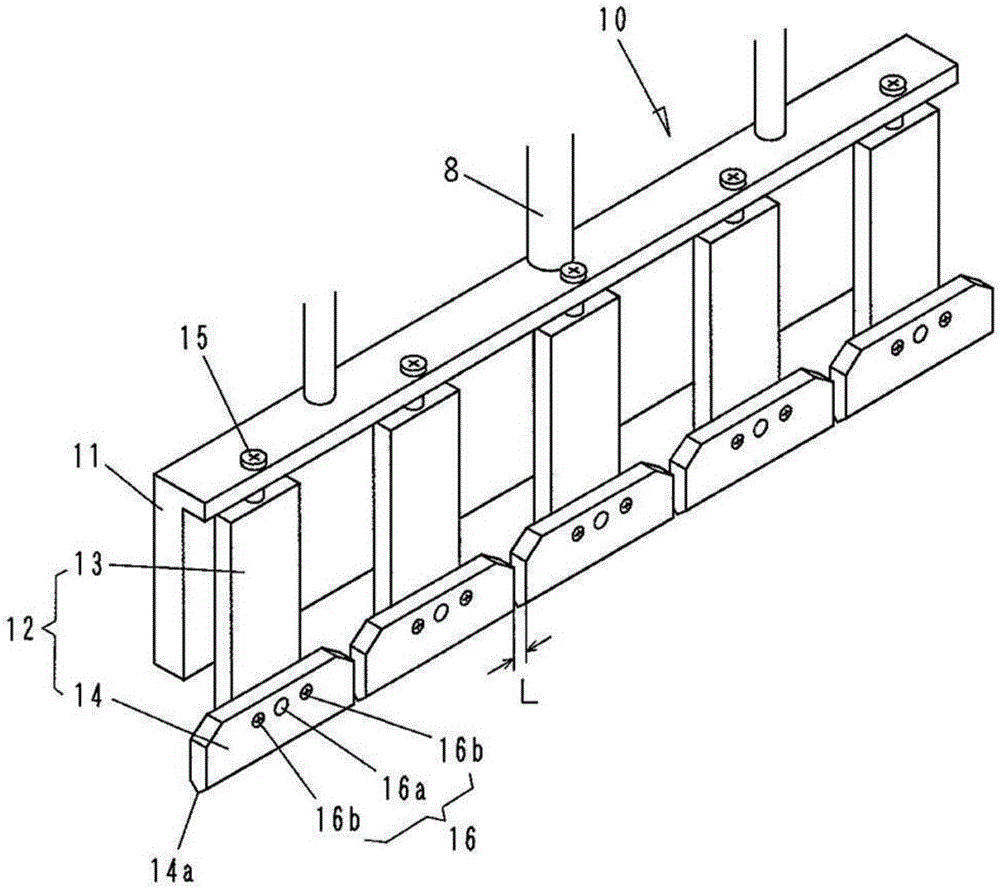

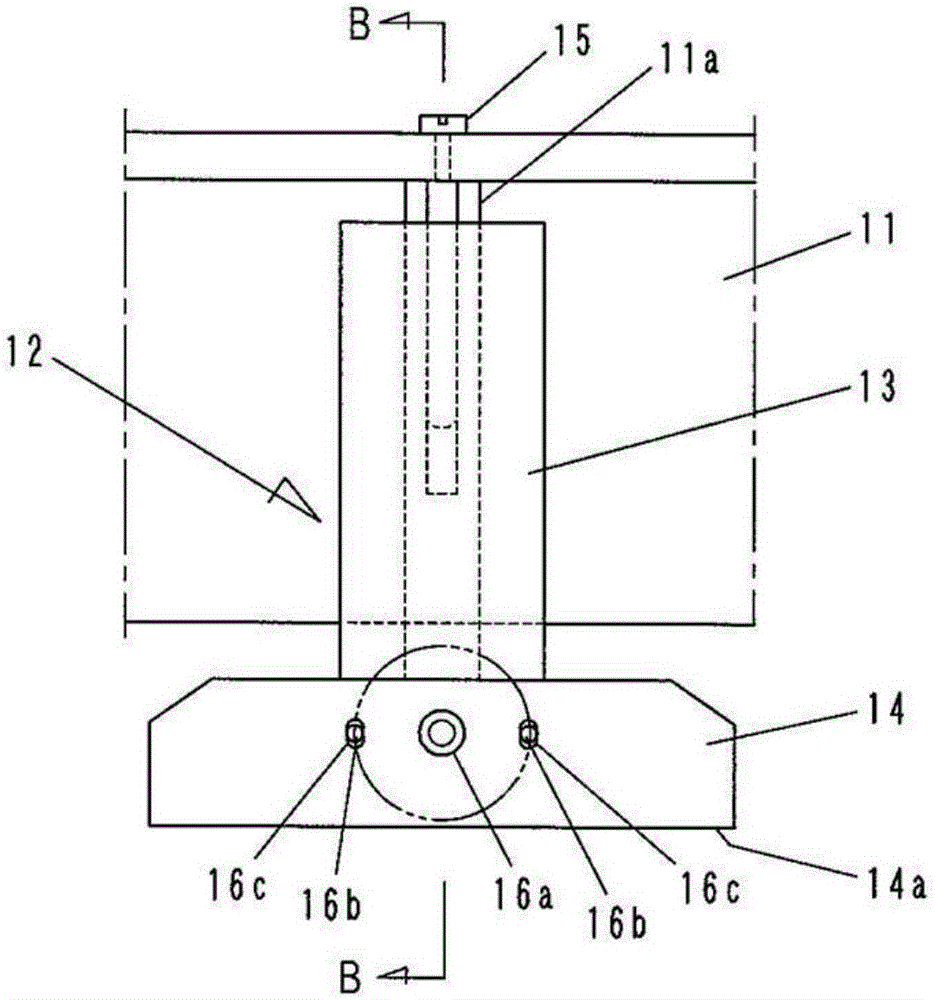

[0028] Hereinafter, details of the cutting device of the present invention will be described based on the accompanying drawings. figure 1 It is a perspective view showing a schematic overall structure of the cutting device of the present invention, Figure 2-4 is showing figure 1 Diagram of the details of the severed strips shown.

[0029] Such as figure 1 As shown, the cutting device A of the present invention is formed to have a table 1 having a mounting surface 1a for mounting a substrate W, and a plurality of suction holes (not shown) are provided on the surface of the table 1. ), the substrate W is adsorbed and held by sucking air through the suction hole.

[0030] In addition, the table 1 can move in the Y direction along the horizontal rail 2 by the screw shaft 4 rotated by the motor 3 . Furthermore, the table 1 can be rotated in a horizontal plane by the rotation drive part 5 which built-in the motor.

[0031] A gate-shaped support body is formed by supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com