A kind of environmental protection equipment with high crushing efficiency to prevent jammed materials

A technology of crushing efficiency and environmental protection equipment, applied in the direction of grain processing, etc., can solve the problems of the impact of the normal operation of the grinder, the low crushing efficiency of the grinder, and the grinding teeth are not easy to bite plastics, etc., to achieve low maintenance costs, simple structure, and improved crushing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

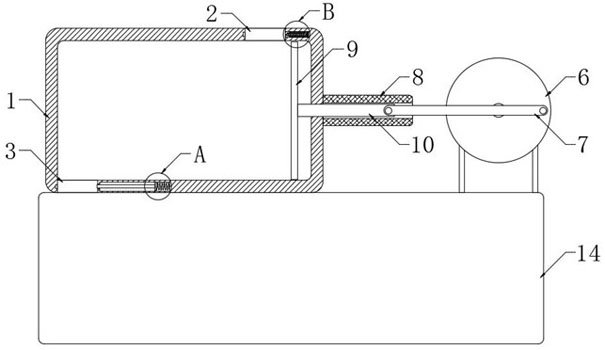

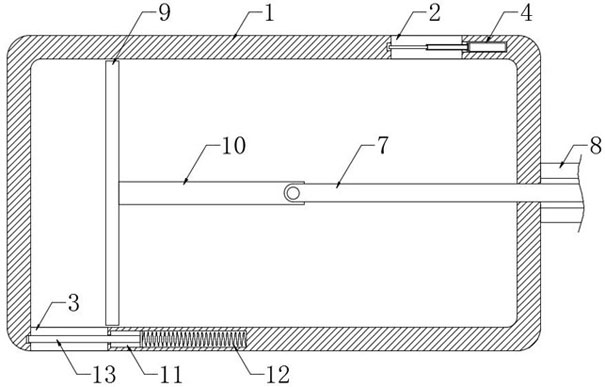

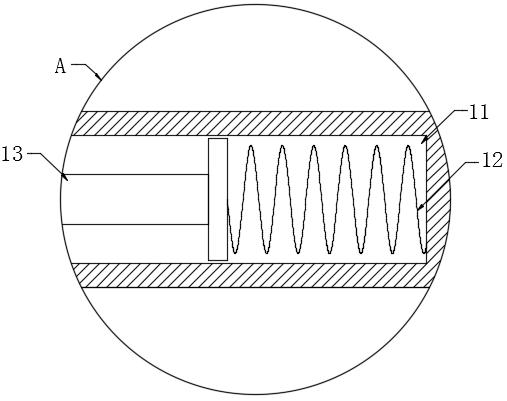

[0025] refer to Figure 1-5 , a kind of environmental protection equipment that prevents the crushing efficiency of jammed materials and is high, comprises processing box 1 and crushing box 14, is provided with crushing mechanism in crushing box 14, and this crushing mechanism is prior art, does not repeat them here, processing box 1 installs At the upper end of the crushing box 14, the upper and lower ends of the processing box 1 are provided with a feed port 2 and a discharge port 3 respectively, and the feed port 2 and the discharge port 3 are respectively located on the opposite sides of the upper and lower end faces of the processing box 1. A feed pipe is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com