Equipment for detecting terminal electrical performance

A technology of electrical performance testing and terminals, applied in the field of transportation testing, can solve the problems of low testing efficiency, increased cost, and more construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

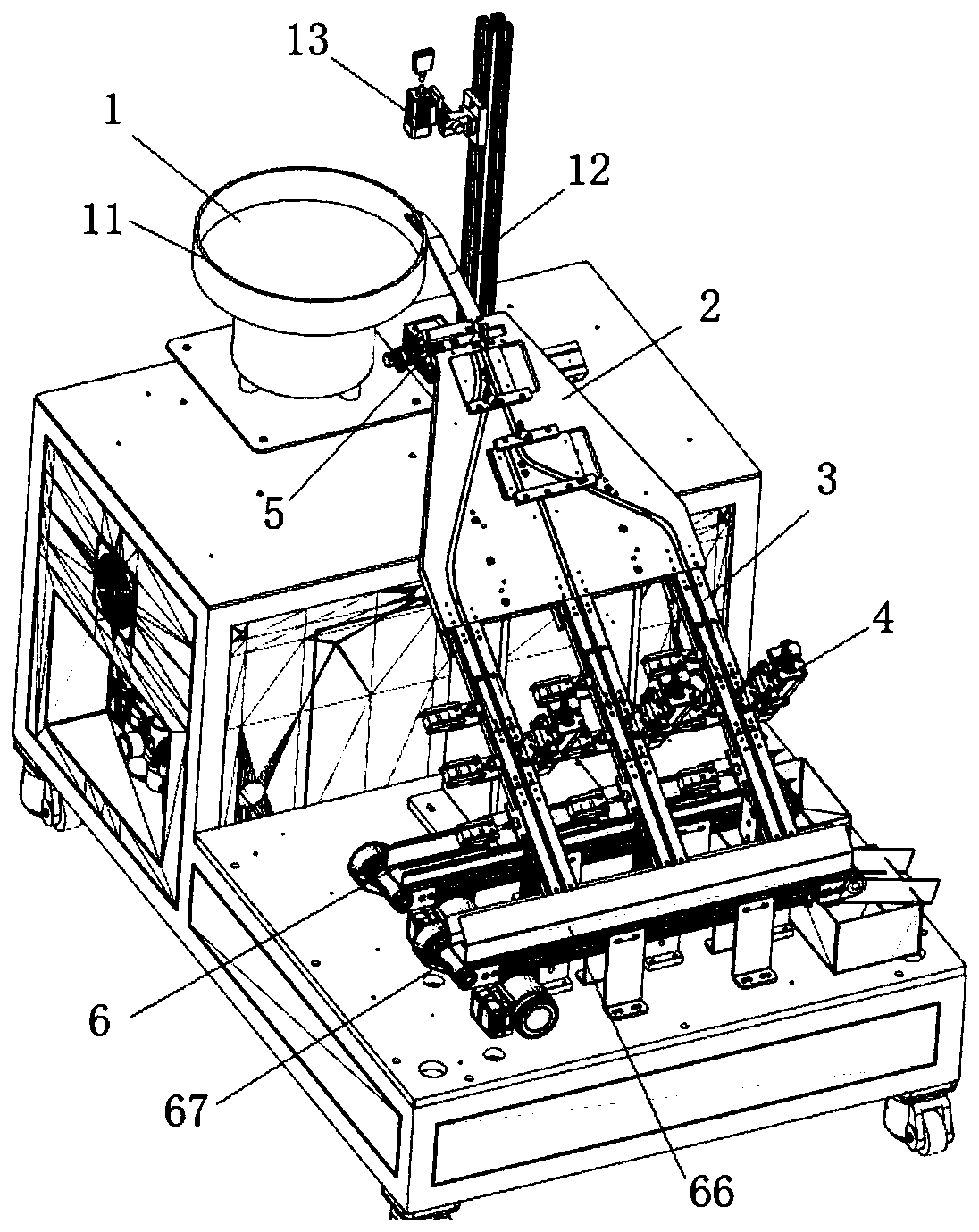

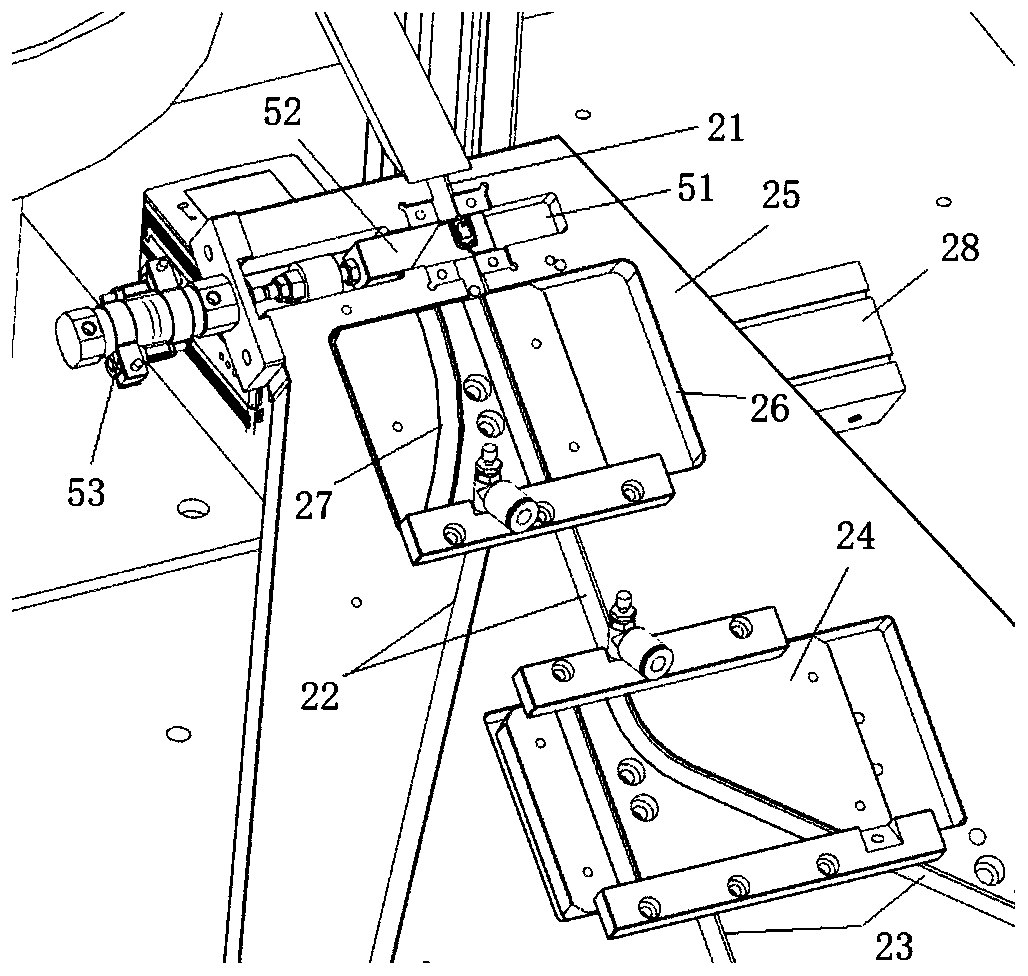

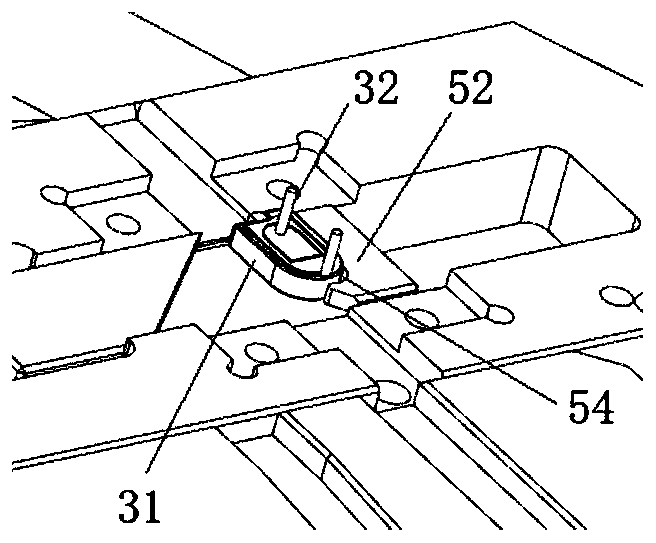

[0029] refer to Figure 1-6 As shown, this embodiment is a terminal electrical performance testing equipment, including a feeding device 1 for transferring materials, a dislocation device 2 arranged at the end of the feeding device 1 for distributing materials to each downstream conveying channel, and a dislocation device 2 arranged at the docking downstream The side of the detection slide rail 3 at the end of the conveying path and the detection device 4 for pressing down on the material 31 for electrification detection, and the material leakage device 6 provided on the detection slide rail 3 for pushing out waste from the side.

[0030] The dislocation device 2 comprises some multi-stage material passing plates 24, a main conveying path 21 and some descending conveying paths, and the descending conveying path comprises a secondary conveying path 22 and a branch conveying path 23; Distributed to several downstream conveying lanes 22, the single secondary conveying lane 22 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com