Steel reinforcing bar correcting device for reinforced concrete

A technology for reinforced concrete and steel bars, applied in the field of correcting devices for steel bars used in reinforced concrete, can solve problems affecting concrete pouring effects, deformation, and affecting the safety of construction projects, and achieve the effects of avoiding deformation, convenient use, and beneficial use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

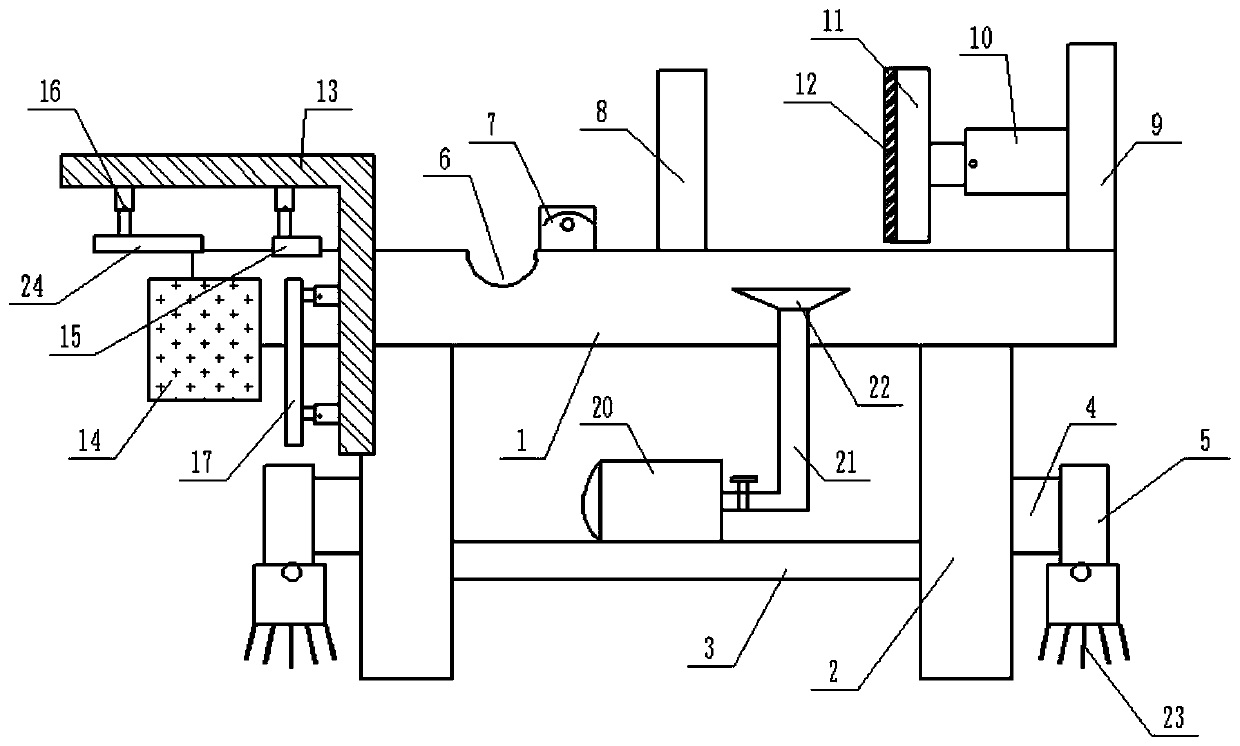

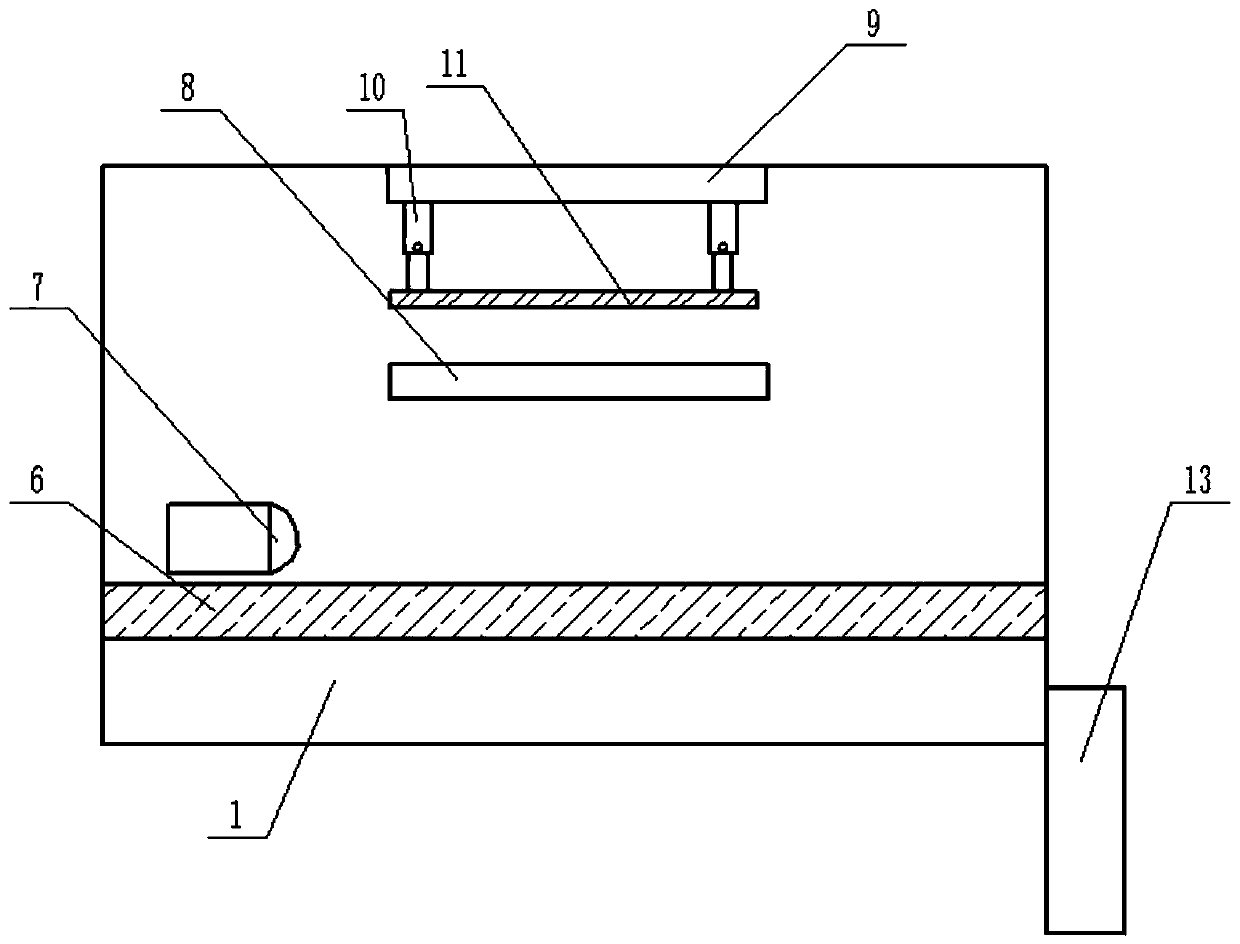

[0021] Example 1: Please refer to Figure 1-3 A straightening device for steel bars for reinforced concrete, comprising a workbench 1, the bottom end of the workbench 1 is provided with a support leg 2, the support legs 2 ensure the stability of the device, and facilitate the safety of the steel bar correction work for concrete.

[0022] The workbench 1 is provided with a steel bar placement groove 6, and there is a laser light 7 on one side of the steel bar placement groove 6. The concrete steel bars are placed in the steel bar placement groove 6, and the laser light 7 is used to shoot the laser along the steel bar placement groove 6, and the contrast is emitted. The advanced laser and steel bars can detect whether the steel bars are bent, which is convenient for subsequent corrections, which is conducive to ensuring the safety of the bearing force of the steel bars after concrete pouring, avoiding deformation and other safety hazards, and is convenient to use.

[0023] The w...

Embodiment 2

[0027] Embodiment 2: On the basis of Embodiment 1, a pull plate 3 is provided between the supporting legs 2, and the pull plate 3 increases the stability of the device and is convenient to use.

[0028] The supporting leg 2 is provided with a connection block 4, the connection block 4 is connected to the top of the lifting column 5, and the bottom of the lifting column 5 is provided with a fixed claw 23. Before working at the bottom working place, adjust the lifting column 5 so that the fixed claw 23 tightly grasps the ground , avoid its sliding, ensure the stability of the device, facilitate the correction of steel bars for concrete, and improve safety.

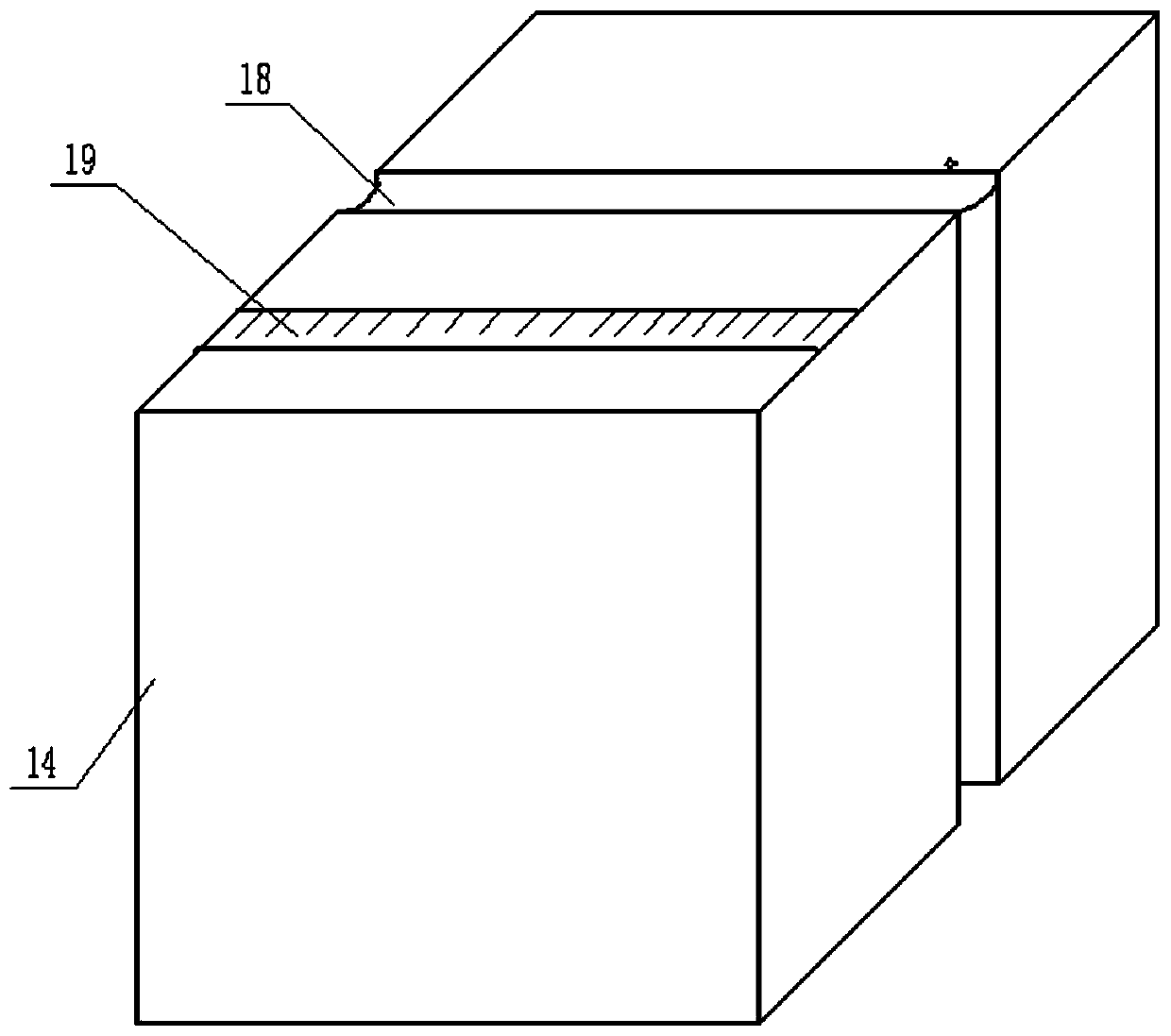

[0029] The fixed square column 14 is provided with a groove 18, and the groove 18 is convenient for reinforcing bars to be placed thereon, avoiding its rolling, and being beneficial to the preparation of stirrups.

[0030] Fixed square column 14 is provided with ruler 19, and ruler 19 is beneficial to measure the degree when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com