Vehicle A column blind area eliminating device based on negative Fresnel lens and matching method

A Fresnel lens and lens technology, applied in the direction of lens, optical observation device, installation, etc., can solve the problems of delay, high cost, complex structure, etc., and achieve the effect of eliminating the blind area of A-pillar, easy promotion, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

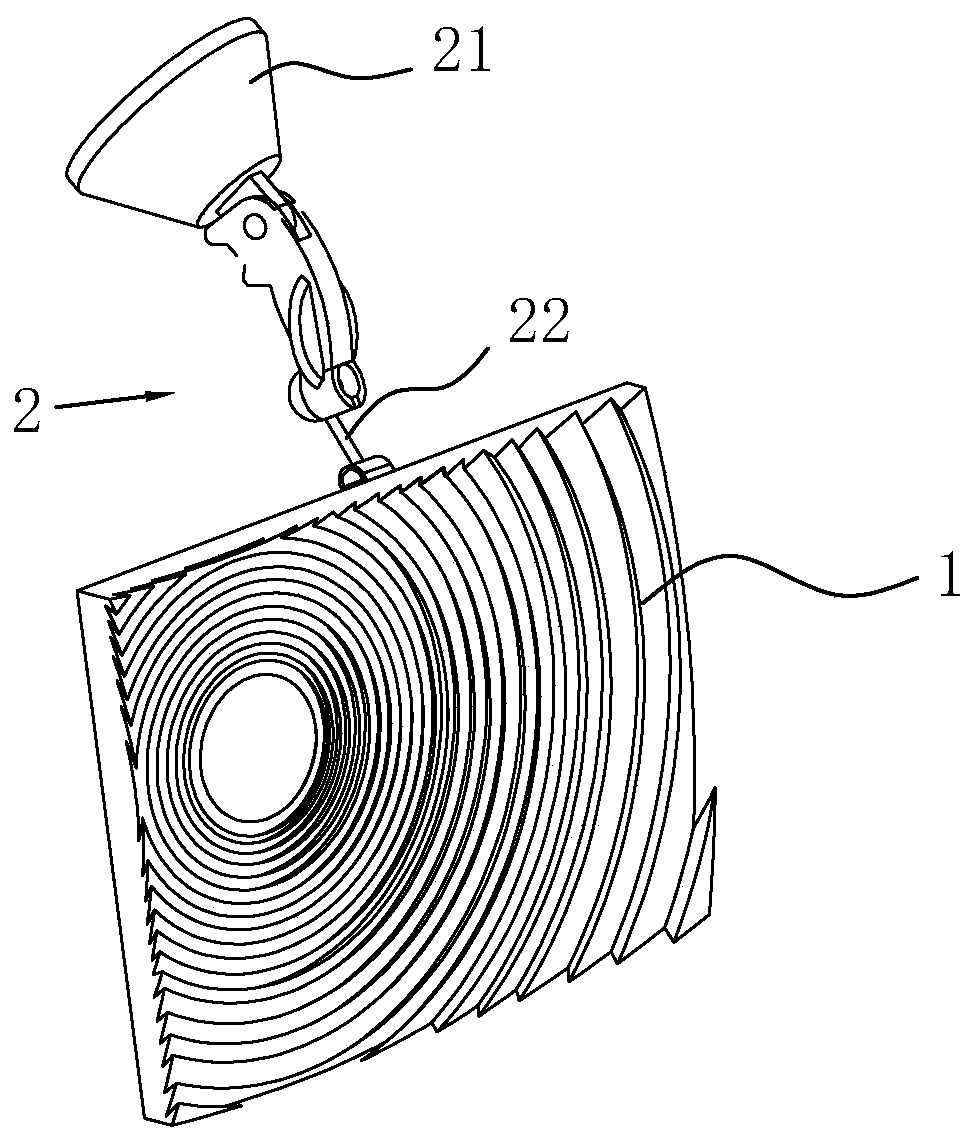

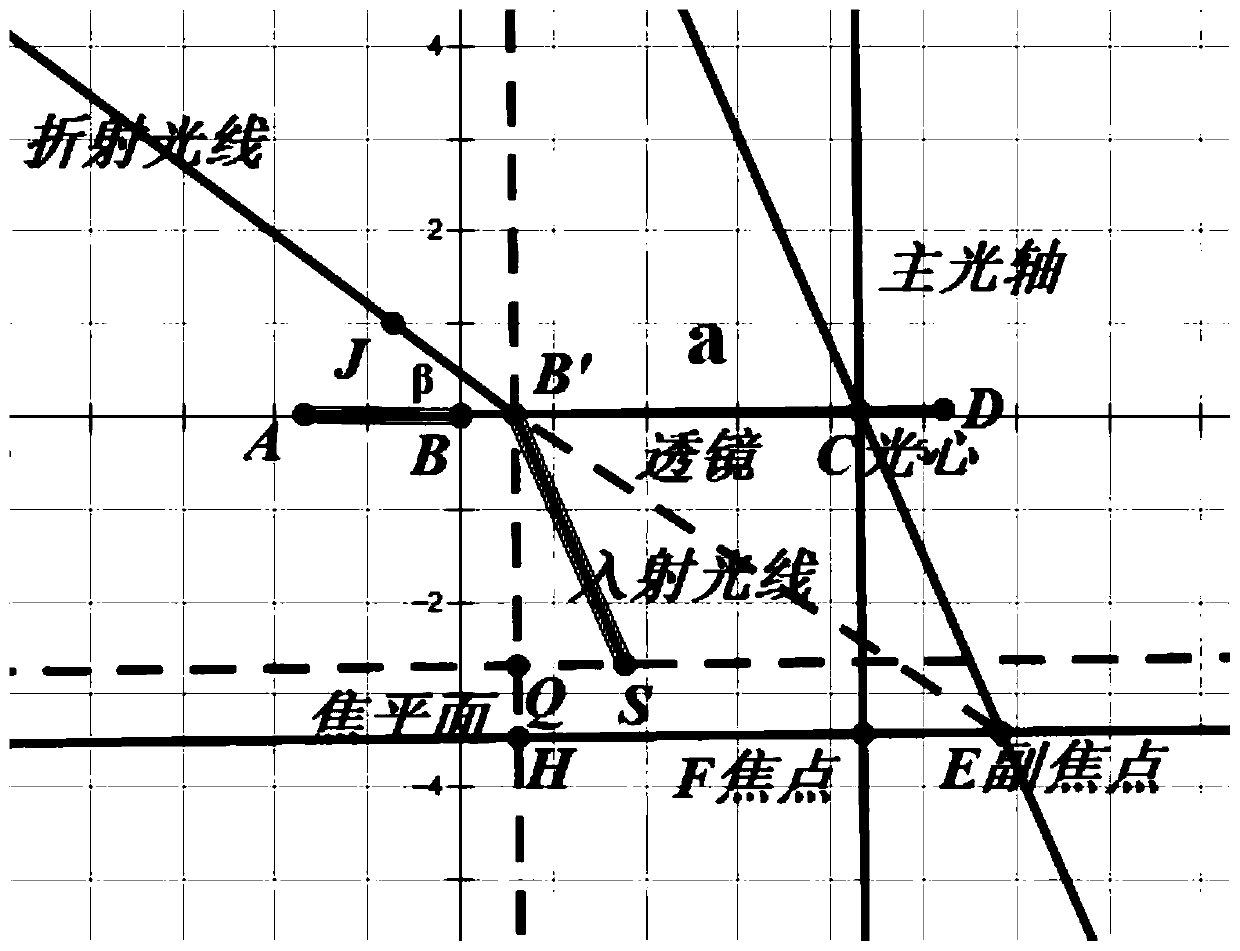

[0226] Embodiment 1: (applied to MPV, SUV and sedan)

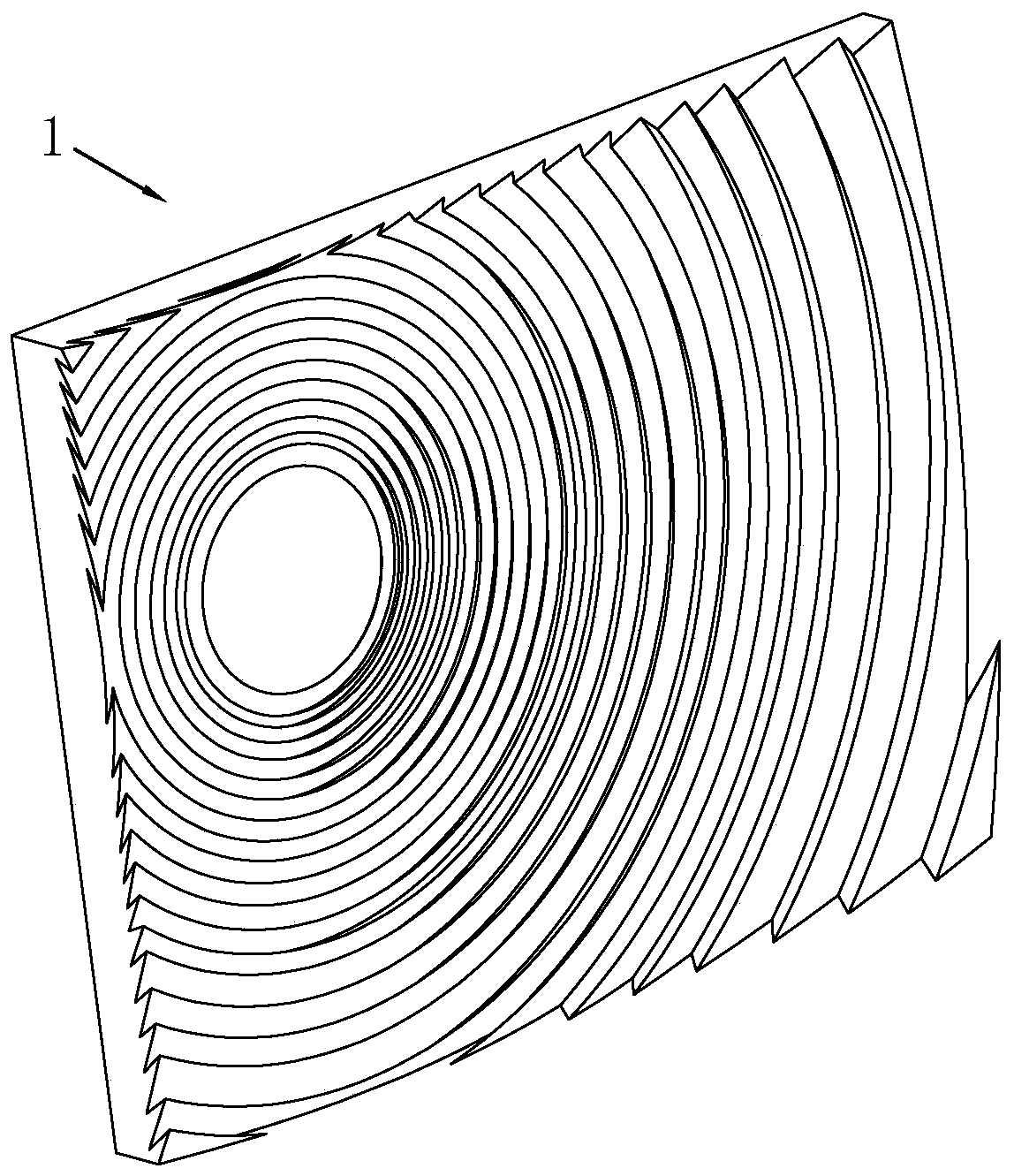

[0227] S31: Select a negative Fresnel lens 1 with a focal length of f=-330mm (where the focal length f=-330mm is only a randomly selected negative Fresnel lens 1 with a smaller focal length, without other uniqueness), and use the negative Fresnel lens Er lens 1 center (concentric circle center) is an angle, obtains long=wide=8cm size (this size is the comparatively suitable size selected according to the model of MPV, SUV and car);

[0228] S32: Sit in the driving position and adjust to the daily driving posture, then face the threaded surface of the negative Fresnel lens 1 to the human body, rotate the negative Fresnel lens 1 so that the center of the negative Fresnel lens 1 (the center of the concentric circle) ) is placed in the upper right corner, and then the center of the upper edge of the negative Fresnel lens 1 is fixed to the position of the connecting part 22 of the suction cup 2 through double-sided adhesive tap...

Embodiment 2

[0235] Embodiment 2: (applied to bus)

[0236] S31: Select a negative Fresnel lens 1 with a focal length of f=-330mm (where the focal length f=-330mm is only a randomly selected negative Fresnel lens 1 with a smaller focal length, without other uniqueness), and use the negative Fresnel lens Er lens 1 center (concentric circle center) is an angle, obtains long=wide=8cm size (this size is the comparatively suitable size selected according to the model of MPV, SUV and car);

[0237] S32: Sit in the driving position and adjust to the daily driving posture, then face the threaded surface of the negative Fresnel lens 1 to the human body, rotate the negative Fresnel lens 1 so that the center of the negative Fresnel lens 1 (the center of the concentric circle) ) is placed in the upper right corner, and then the center of the upper edge of the negative Fresnel lens 1 is fixed to the position of the connecting part 22 of the suction cup 2 through double-sided adhesive tape;

[0238] S3...

Embodiment 3

[0244] Embodiment 3: (applied to MPV, SUV and sedan)

[0245] S41: Select a negative Fresnel lens 1 with a focal length of f=-330mm (where the focal length f=-330mm is only a randomly selected negative Fresnel lens 1 with a smaller focal length, without other uniqueness), and use the negative Fresnel lens The center of lens 1 (the center of concentric circles) is an angle, and the size of 20cm×25cm is obtained (this size is a relatively suitable size selected according to the models of MPV, SUV and sedan);

[0246] S42: Sit in the driving position and adjust to the daily driving posture, then face the threaded surface of the negative Fresnel lens 1 to the human body, rotate the negative Fresnel lens 1 so that the center of the negative Fresnel lens 1 (the center of the concentric circle) ) in the upper right corner, and then fix the center of the upper edge of the negative Fresnel lens 1 to the connecting part 22 of the suction cup 2 through double-sided adhesive tape.

[024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com