Pre-oxidation furnace with end-to-end blowing structure

A pre-oxidation furnace, end-to-end technology, applied in the field of oxidation furnace, can solve the problems of large sag, unfavorable installation of air outlet devices, etc., and achieve the effect of solving inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

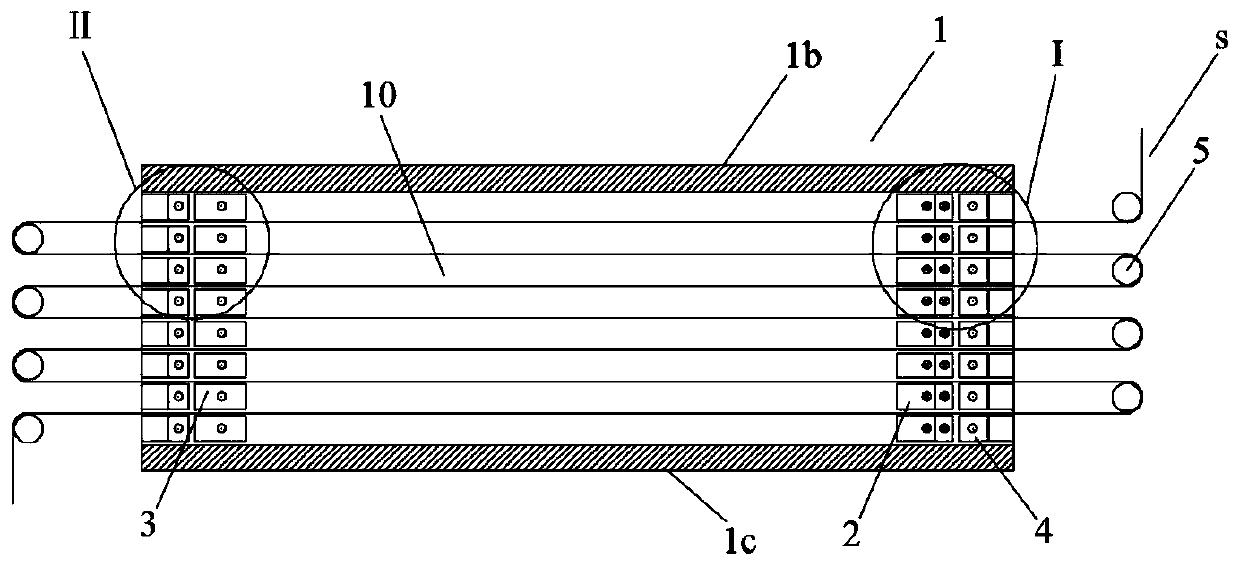

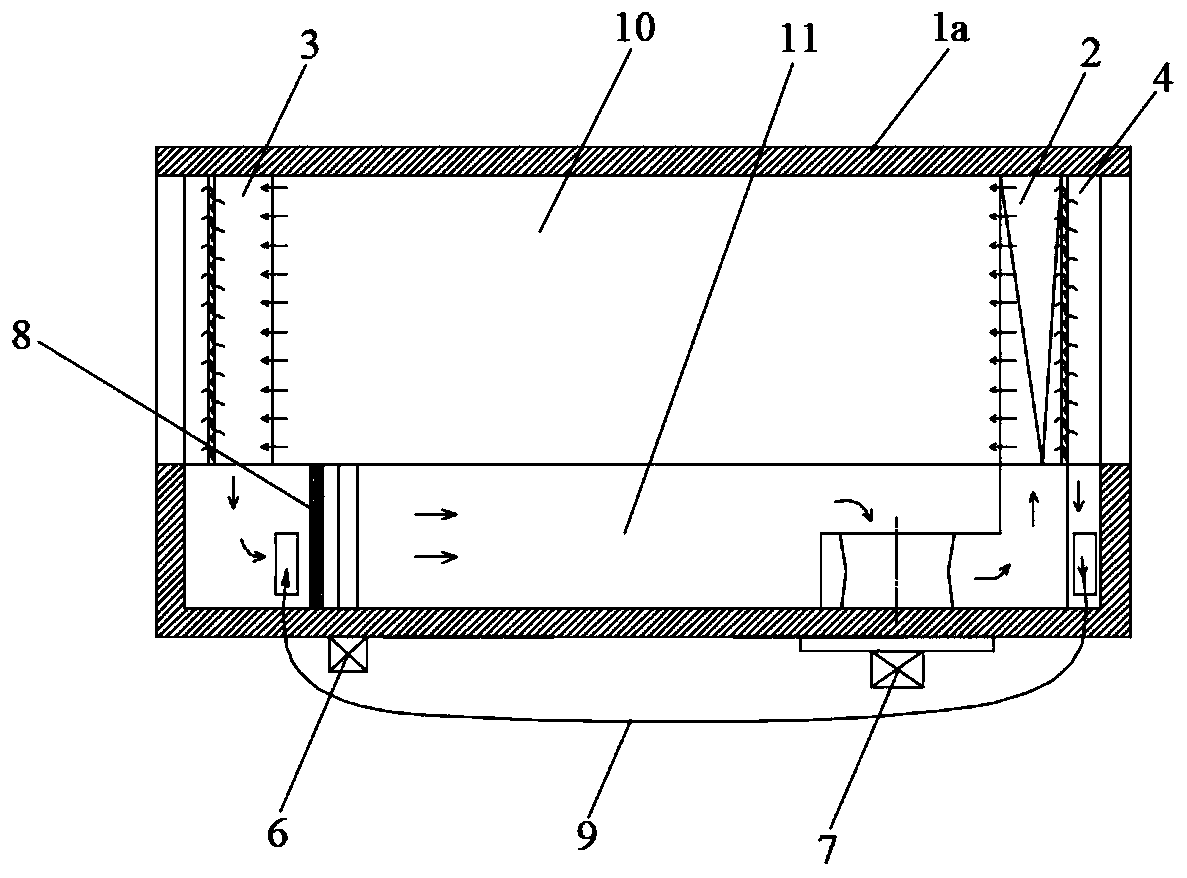

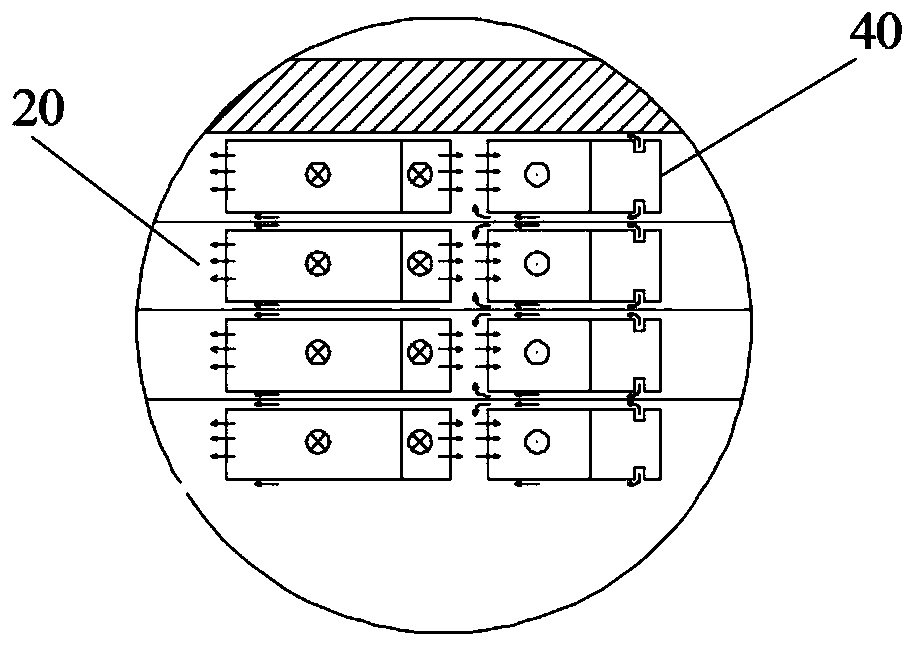

[0049] Such as Figure 1-7 As shown, the pre-oxidation furnace of the end-to-end blowing structure of the present embodiment includes a furnace body 1 and an air outlet device 2 installed in the furnace body, a first air return device 3 and a second return air device 4, and also includes a corresponding The guide roller 5 that the left and right ends of furnace body 1 is installed.

[0050] Such as figure 1 and 2 As shown, the furnace body 1 is surrounded by two vertical side walls 1a opposite in the length direction, two vertical end walls opposite in the width direction, a top wall 1b, and a bottom wall 1c. Hollow rectangular parallelepiped structure; the end walls at the left and right ends of the furnace body have seven groups of through-holes arranged at vertical intervals (the number of through-hole groups is not limited to the seven groups in this embodiment, and can be freely designed according to actual needs).

[0051] Such as figure 2 As shown, the furnace body...

Embodiment 2

[0059] The difference between the preoxidation furnace of the end-to-end blowing structure of the present embodiment and embodiment one is:

[0060] Such as Figure 8 As shown, a first mesh plate A corresponding to the first air return port and a second mesh plate B corresponding to the second air return port are installed in the furnace body to ensure the uniformity and stability of the return air.

[0061] The long-term movement of the pre-oxidation furnace will easily block the first mesh plate A and the second mesh plate B; therefore, it is necessary to clean the first mesh plate and the second mesh plate online, specifically, as Figure 9 and 10 As shown, the furnace body of the present embodiment has a draw-in port C corresponding to the first mesh plate and the second mesh plate one by one, and the draw-in port C is equipped with a thermal insulation sealing plug D. By pulling out the insulation sealing plug, the first mesh plate or the second mesh plate can be pulled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com