Cloth edge control method in sewing process

A control method and sewing technology, applied in the field of sewing, can solve problems such as discontinuous instructions, complex algorithms, poor reliability, etc., and achieve the effect of beautiful stitches, easy realization, and accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

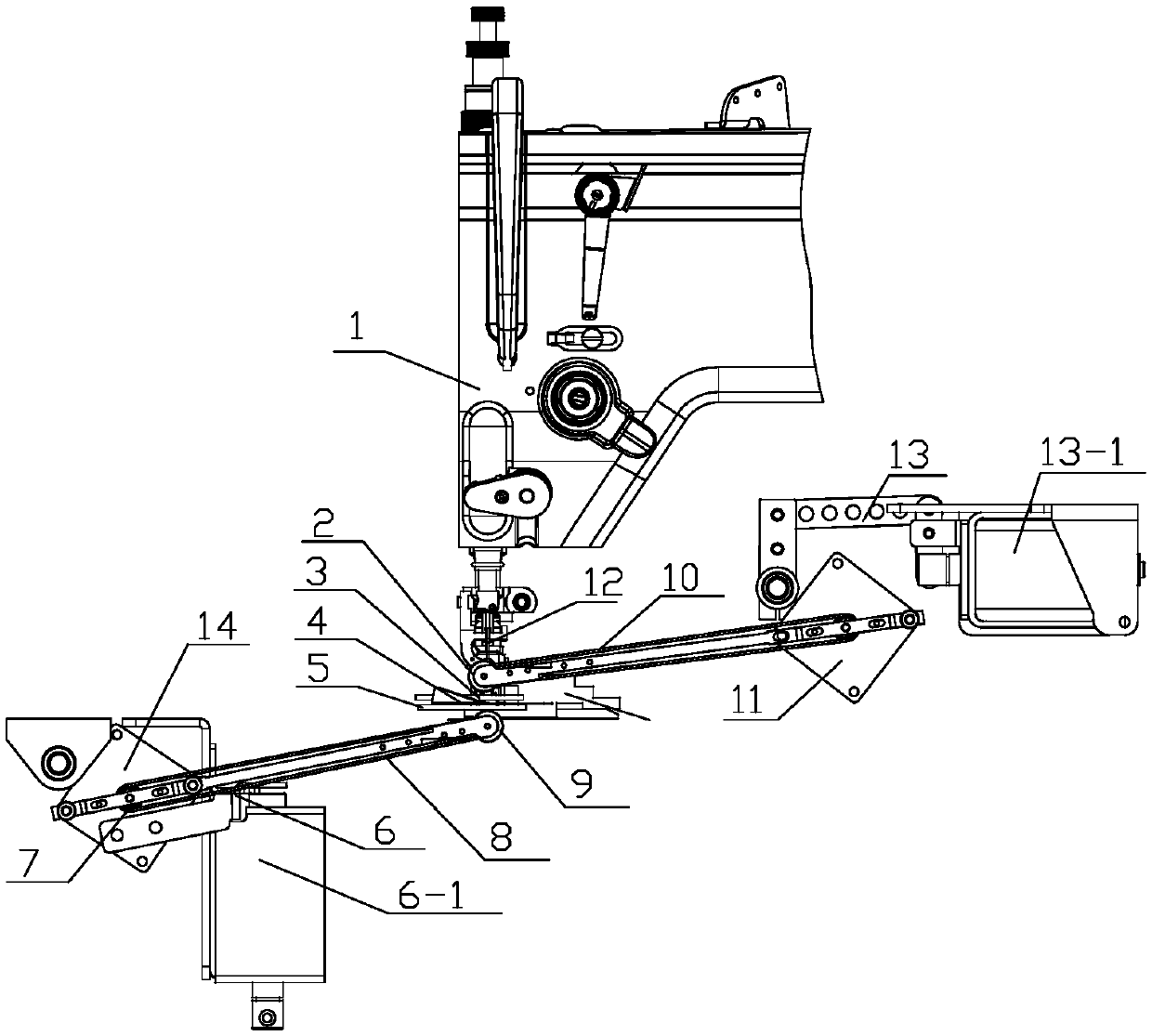

Examples

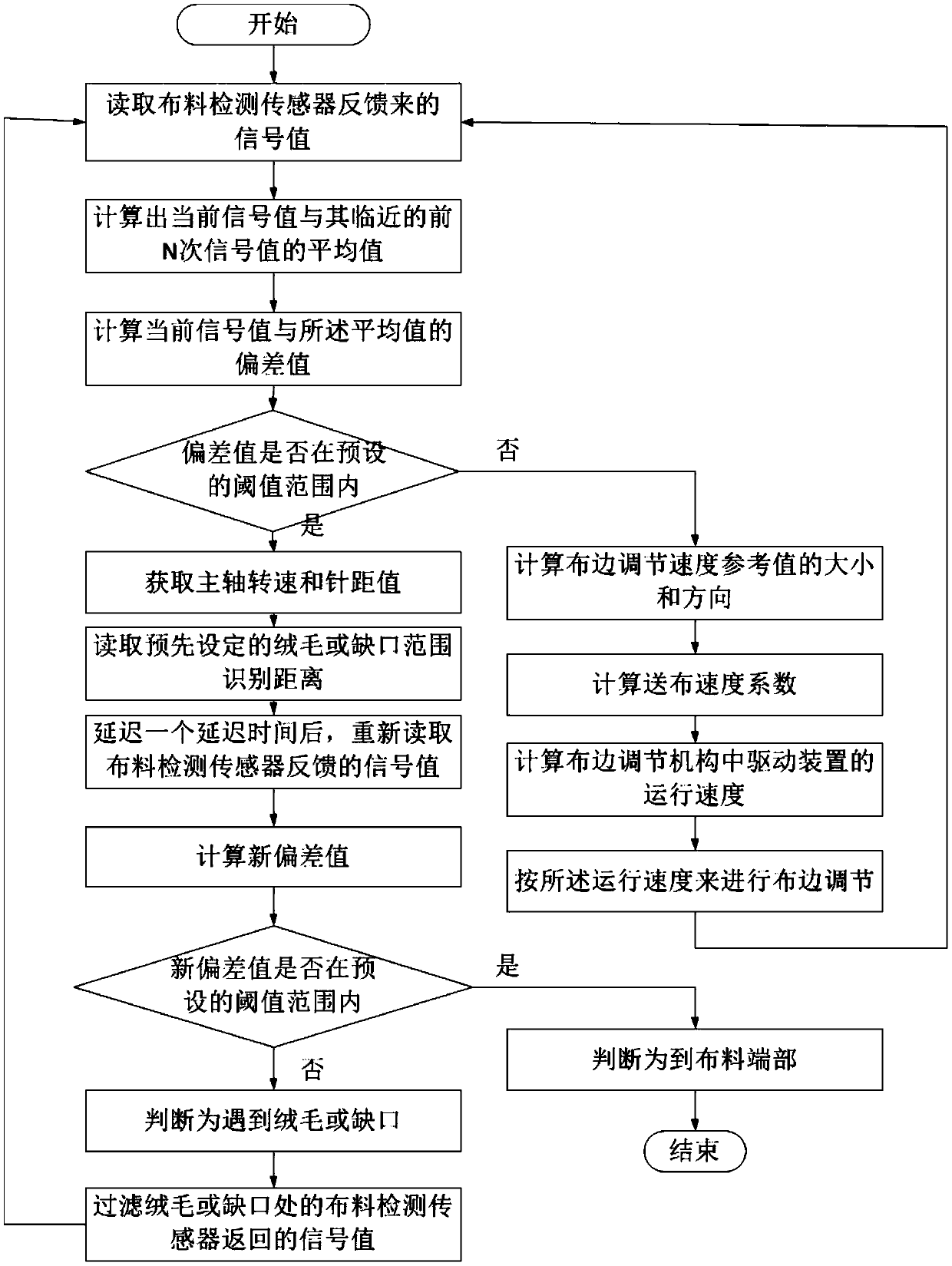

Embodiment 1

[0053] In this embodiment, the specific method for the control unit in step 1) to control the movement of the selvedge adjustment mechanism is: the control unit calculates the cloth feeding speed coefficient in real time according to the preset spindle speed and needle pitch value of the sewing machine, and, according to The current signal value and the aforementioned average value are used to calculate the size and direction of the reference value of the edge adjustment speed, and the reference value of the edge adjustment speed is multiplied by the cloth feeding speed coefficient to obtain the operating speed of the driving device in the edge adjustment mechanism, and the control unit Outputting control commands to the driving device to make the driving device adjust the selvedge according to the running speed; if the driving device is a motor, the running speed of the driving device is the running speed of the motor.

[0054] The specific calculation process of the running s...

Embodiment 2

[0062] The specific judgment process of fluff or gap in the above step 2) is:

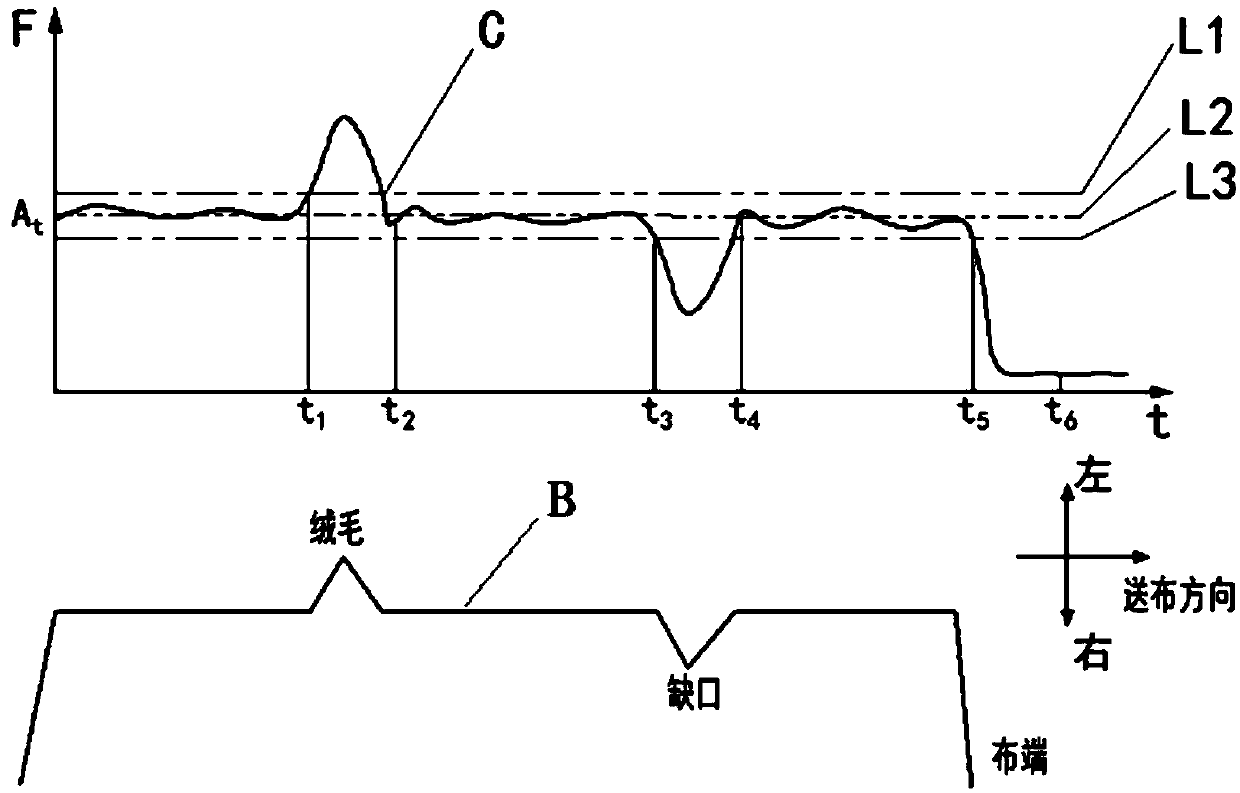

[0063] The fabric detection sensor detects the fabric in real time. When there are fluff or gaps in some positions of the fabric edge, the return value (ie, the current signal value) detected by the fabric detection sensor will be significantly larger or smaller. Record the current signal value as f m , if no corresponding measures are taken, even if the cloth is in the correct position at this time, it will be adjusted in one direction. At this time, after comparing the average value calculated according to the above-mentioned moving average algorithm with the current signal value, if the deviation value exceeds the preset threshold range in the control unit, it is judged that there may be fluff or gaps here. At this time, The control unit outputs relevant signals, and the selvedge adjustment mechanism stops acting. The control unit reads the pre-set fluff or notch recognition distance l, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com