Clamping type electric heater cover plate

An electric heater and snap-fit technology, which is applied in the field of snap-fit electric heater cover plates, can solve problems such as water and other liquids contaminating the cover plates, inconvenient assembly and disassembly, and potential safety hazards, and reduce internal circuit short-circuit problems , good connection effect, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

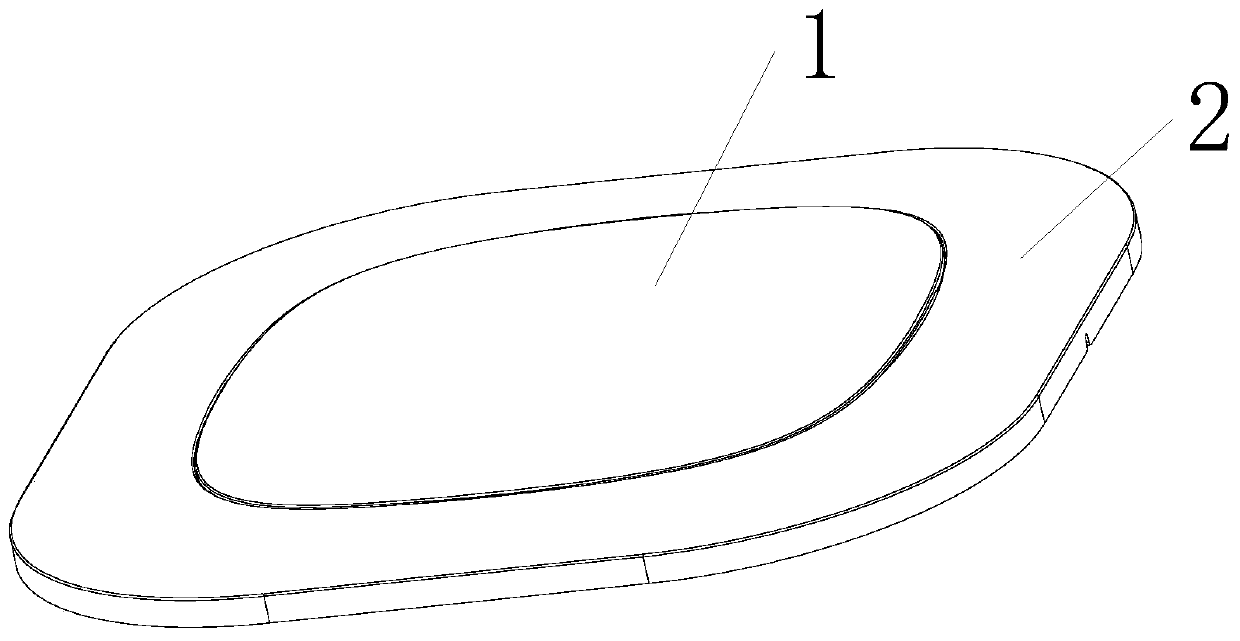

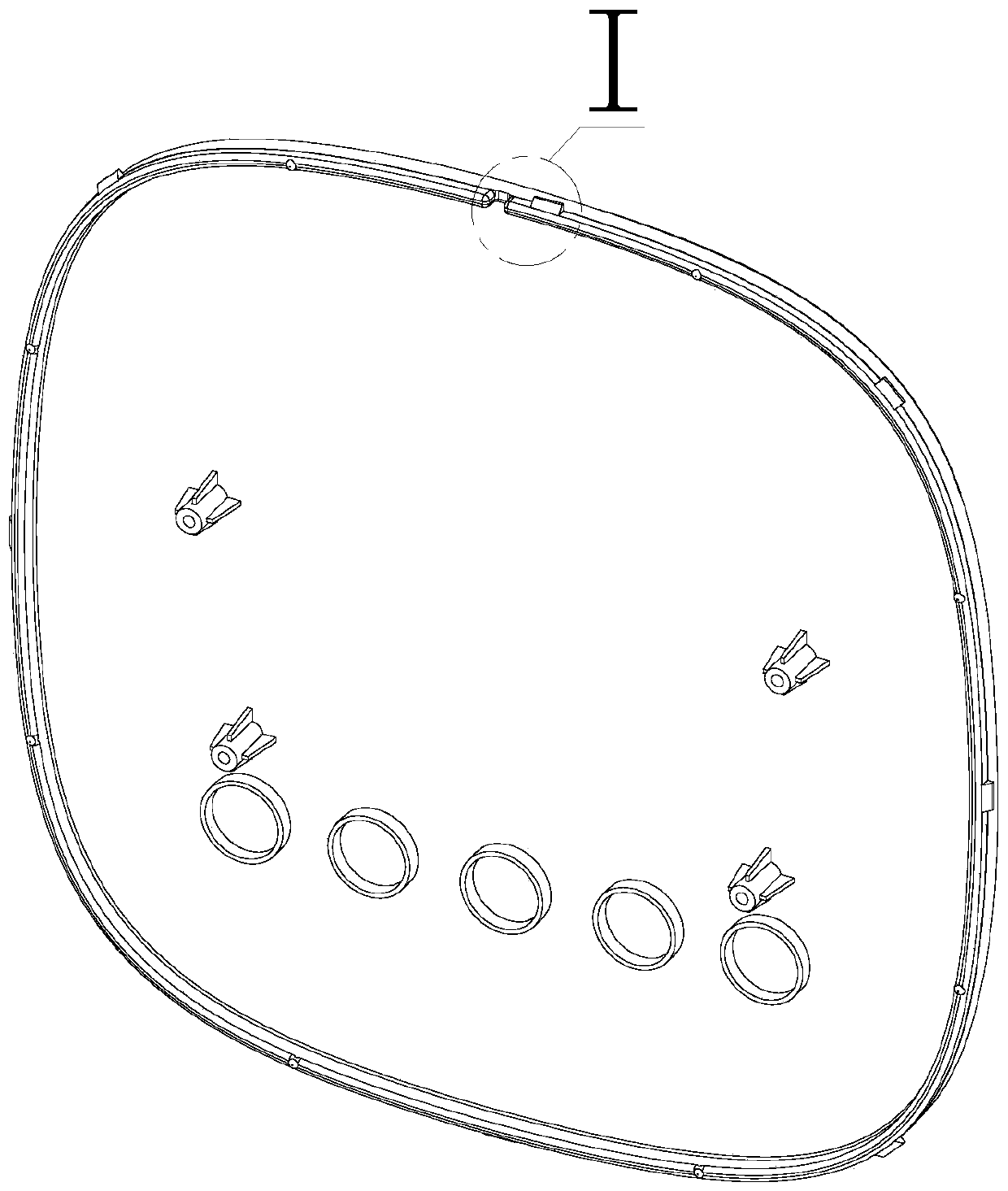

[0017] Such as Figure 1 to Figure 4 As shown, a snap-fit electric heater cover includes a display screen 1 and a top cover 2 that cooperate with each other, and also includes:

[0018] The connection structure is arranged on the display screen 1 and the top cover 2, and is used to realize the connection between the display screen 1 and the top cover 2;

[0019] The waterproof structure is arranged on the top cover 2 and is used to realize waterproofing of the interior.

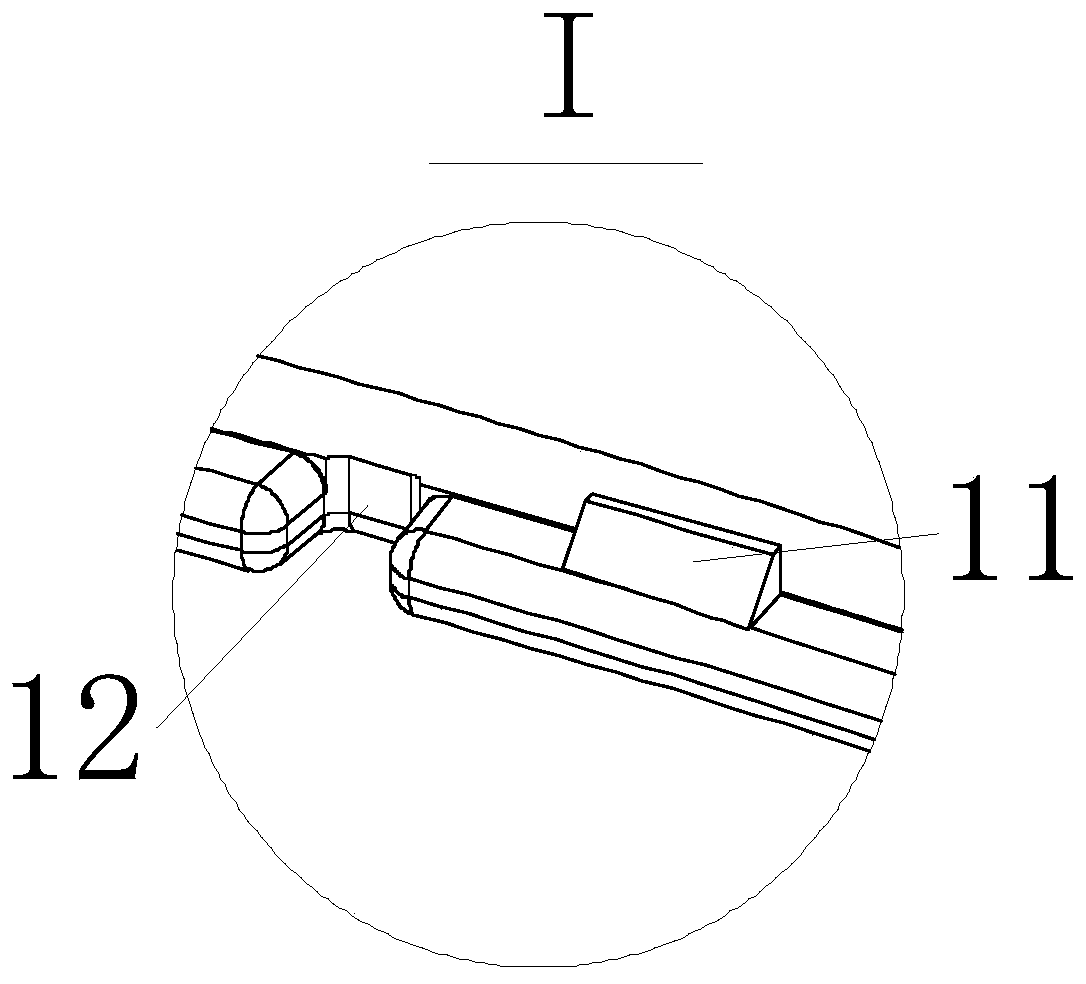

[0020] The connection structure includes several groups of buckles 11 arranged on the display screen 1, buckle grooves 21 arranged on the top cover 2 for one-to-one cooperation with the buckles 11, and several groups of concave holes arranged on the display screen 1. The slot 12 and the top block 22 arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com