Silicon base medium blocking type 1-dimention nano pole structure

A dielectric barrier and nano-electrode technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as deformation and displacement, difficulty in uniform film thickness, and contact, so as to reduce the probability of ignition damage and reduce the electrode Effects of short-circuit problem, stability and life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

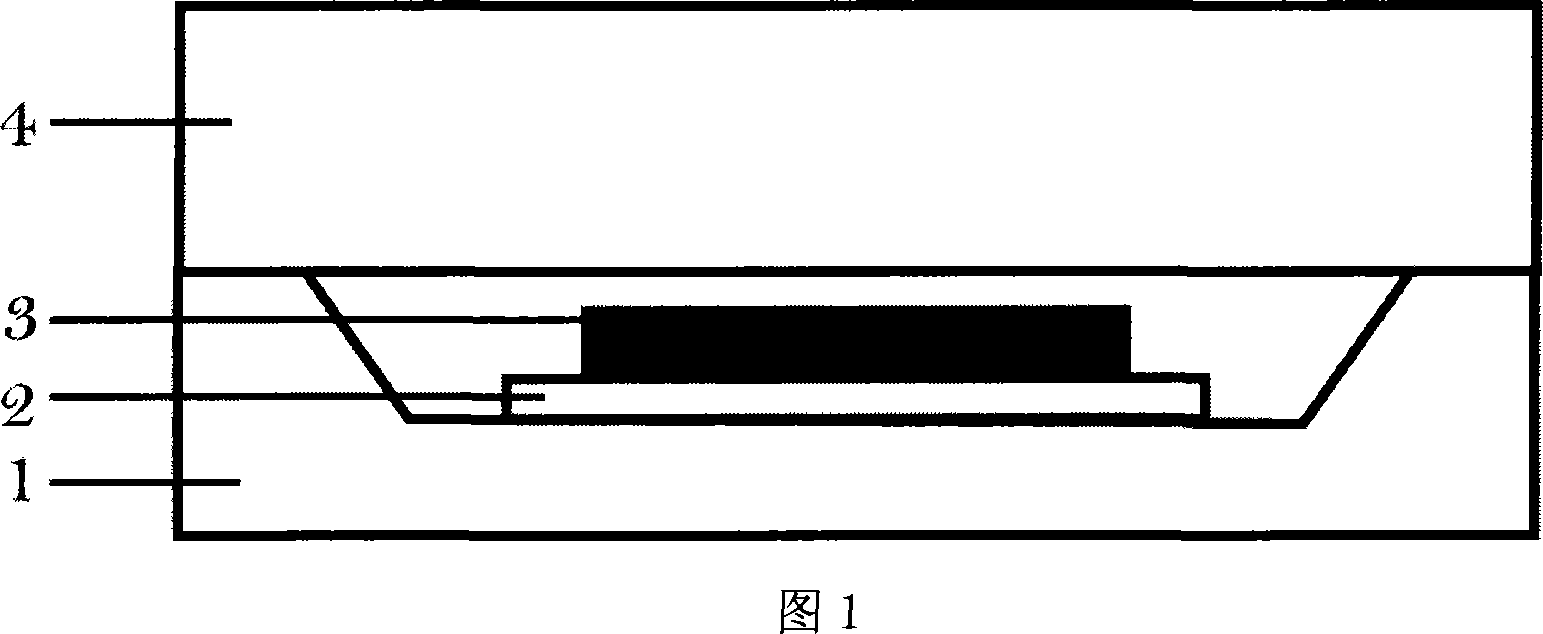

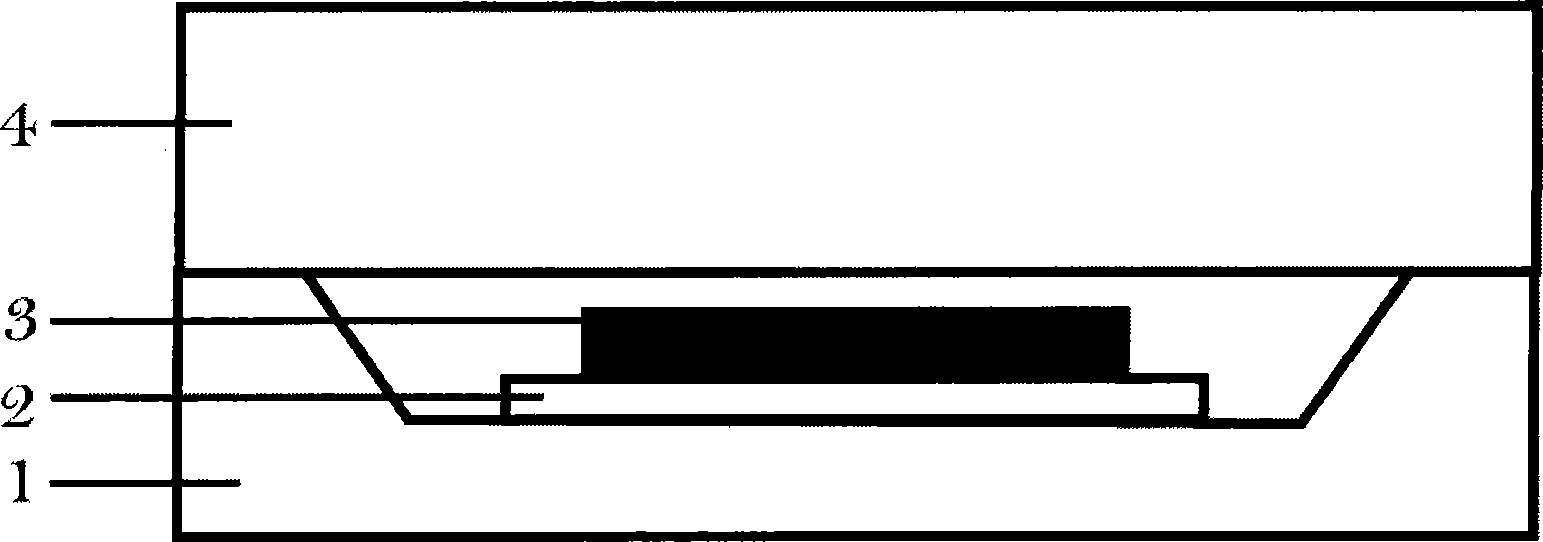

[0017] As shown in Figure 1, this embodiment includes: the electrode structure is formed by bonding two silicon substrates, the upper part and the lower part, and the surface of the lower silicon substrate 1 facing the upper silicon substrate 4 is covered with an insulating layer, and the lower silicon substrate 1 is covered with an insulating layer. Part of the sheet 1 has a pit structure, and a patterned one-dimensional nanomaterial film 3 is arranged in the pit, and a patterned metal conductive layer 2 is arranged on the lower part of the one-dimensional nanomaterial film 3, and the bonded part of the two silicon substrates It is the area around the pit structure of the lower silicon substrate 1, the surface of the upper silicon substrate 4 facing the lower silicon substrate 1 is covered by an insulating layer, and there is an electrode gap between the carbon nanotube film and the upper silicon substrate 4 .

[0018] The one-dimensional nanomaterial film 3, wherein the one-...

example 2

[0025] In this embodiment, the electrode structure is formed by bonding two upper and lower silicon substrates with an area of 8 mm × 8 mm. The surface of the lower silicon substrate 1 facing the upper silicon substrate 4 has a silicon dioxide layer with a thickness of 2 μm. Covered by an insulating layer, the central area of the lower silicon substrate 1 has a square groove-shaped pit structure with an area of 5mm×8mm, and a square carbon nanotube film with an area of 4mm×4mm is arranged in the pit, and the lower part of the carbon nanotube film is arranged There is a Cr / Au metal conductive layer 2 with an area of 4.5mm×8mm square and a thickness of 30nm and 270nm respectively. The metal conductive layer 2 is located in the pit of the lower silicon substrate 1 and serves as the conductive connection layer of the carbon nanotube film. The surface of the upper silicon substrate 4 with an area of 8 mm × 8 mm facing the lower silicon substrate 1 is covered with a silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com