Defect detection method for product of mirror surface bowl-shaped structure

A defect detection and product technology, applied in the field of visual inspection, can solve the problems of reduced imaging contrast, poor imaging of large spots, etc., and achieve the effect of improving quality and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

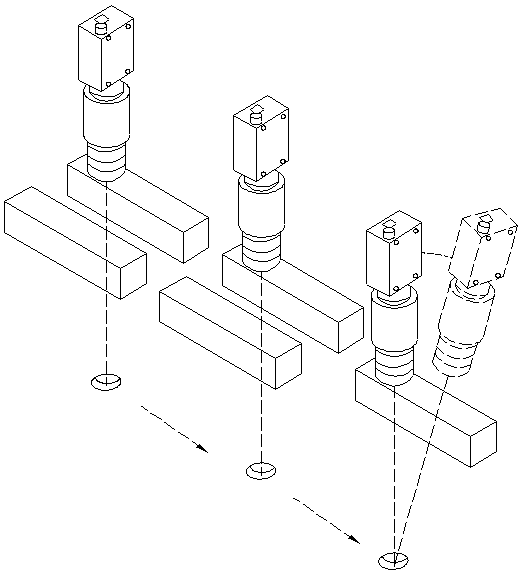

[0026] A defect detection method for mirror bowl-shaped structure products, such as figure 1 The imaging device shown includes a first camera, a second camera and a third camera arranged side by side, the first camera corresponds to the first group of bar light sources, the second camera corresponds to the second group of bar light sources, and the third camera corresponds to the third A group of bar-shaped light sources, the first group of bar-shaped light sources and the second group of bar-shaped light sources have two bar-shaped light sources, and the third group of bar-shaped light sources is one bar-shaped light source.

[0027] During the specific operation, first place the mirror bowl-shaped structure product to be inspected on the carrying table (the carrying table is fixed on the conveyor belt and moves with the conveyor belt), adjust the positions of all cameras, and ensure that all cameras are in an upright state; When the inspection product moves directly under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com