Phase change temperature control device applied to battery pack

A phase-change temperature control and battery pack technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of high cost, low heat dissipation energy at high temperature, and low sealing level, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

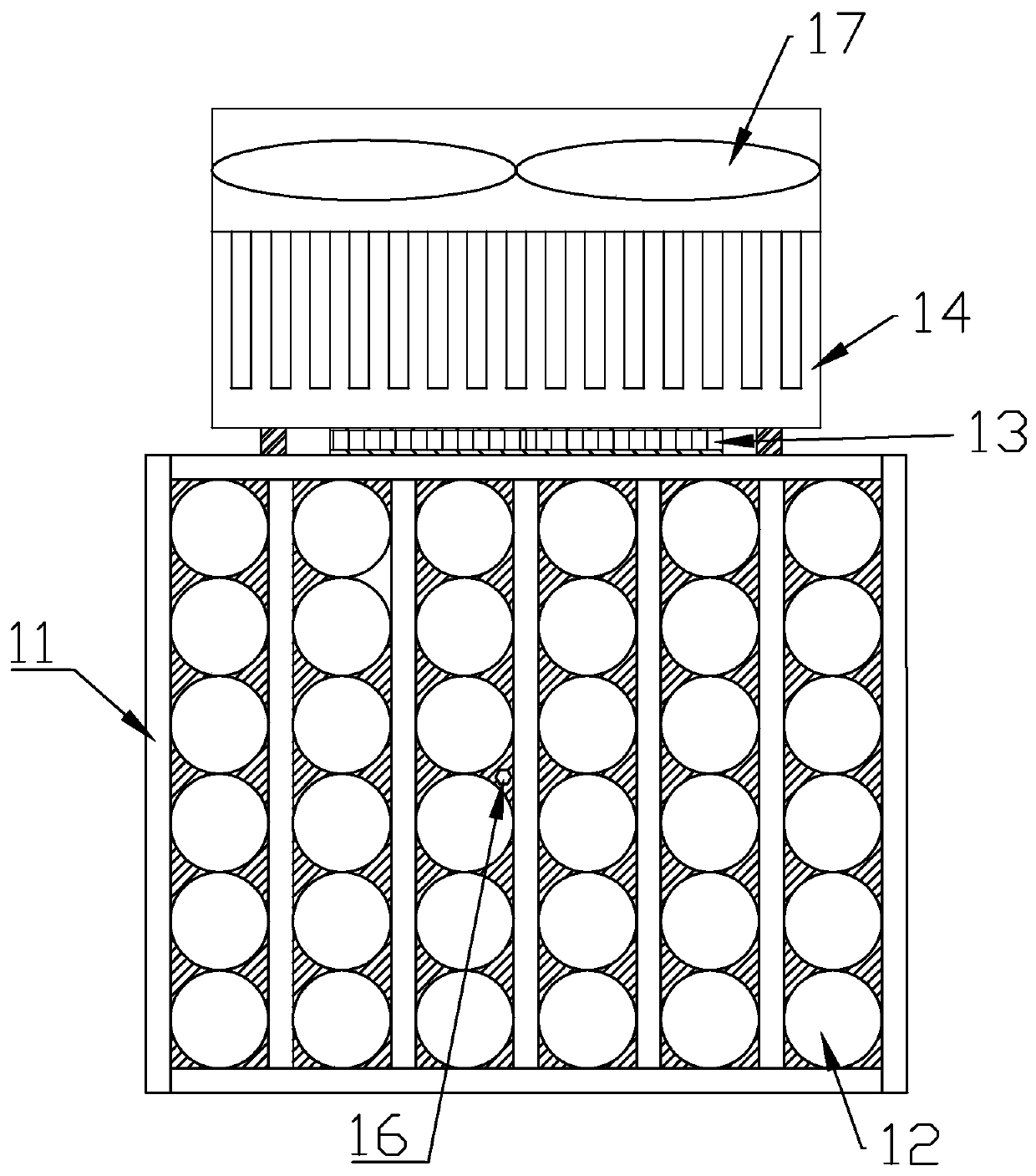

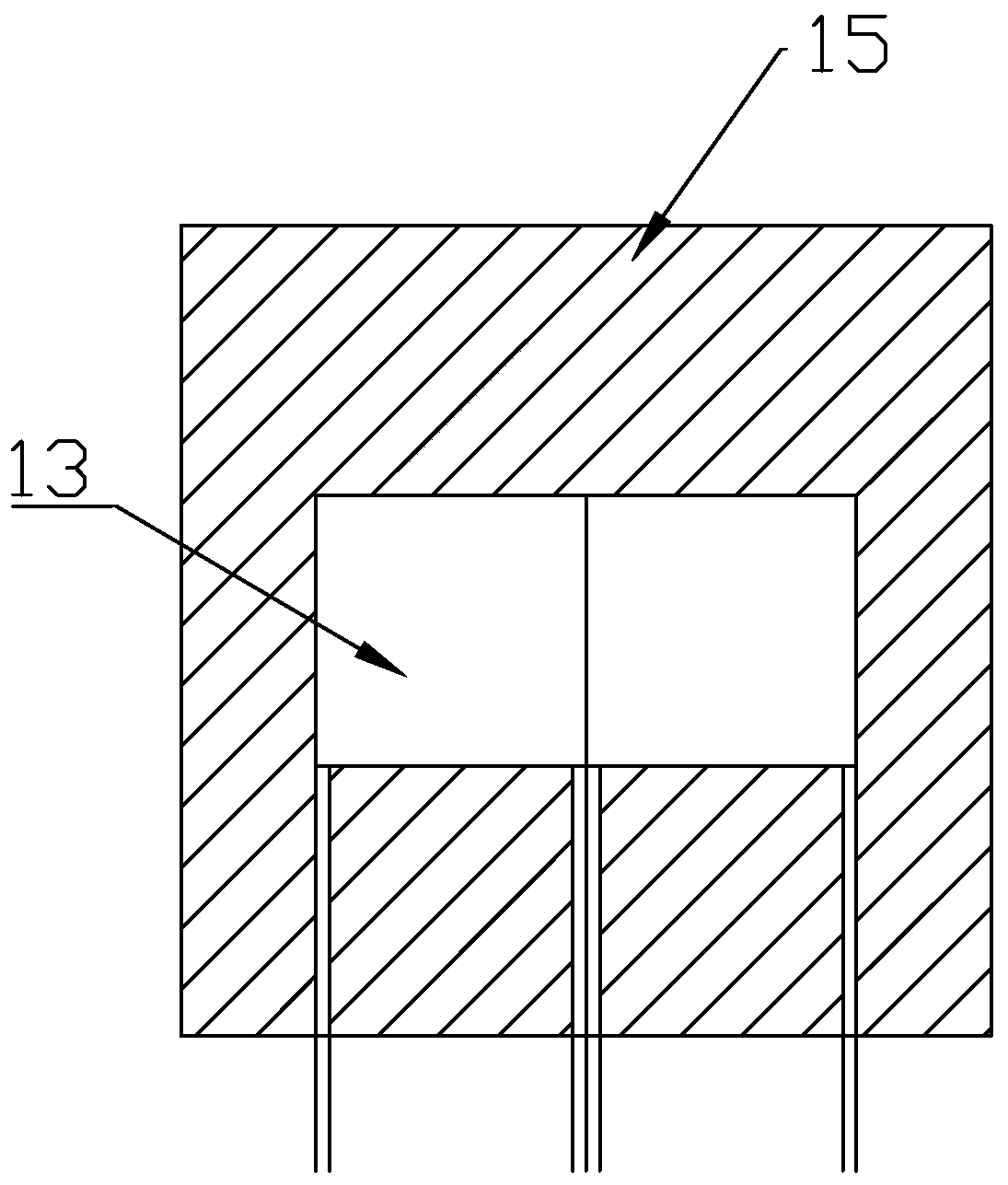

[0018] Combine below Figure 1 to Figure 2 The present invention is further described.

[0019] The invention relates to a phase change temperature control device applied to a battery pack, which includes a casing 11, the side wall of which is a thermally conductive aluminum plate. A temperature control module is arranged on the outer side of the housing 11, and the temperature control module includes a semiconductor cooling chip 13, and the semiconductor cooling chip 13 can be selected as one piece or multiple pieces arranged in an array. A heat insulation board 15 is arranged on the outside of the semiconductor cooling chip 13 , and the semiconductor cooling chip 13 is embedded in the heat insulating board 15 . A plurality of unit cavities 12 for placing batteries are arranged in the housing 11, each unit cavities 12 are arranged in an array, and the spaces between the unit cavities 12 are filled with composite fillers. After the battery is arranged in the unit cavity 12, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com