Auxiliary slot stator punching sheet, stator assembly, motor and compressor

A technology of stator punching and auxiliary slot, which is applied in the fields of auxiliary slot stator punching, stator assembly, motor, and compressor, can solve the problems of large air gap, large energy efficiency loss, and little improvement effect of motor, and achieves the reduction of The effect of air gap magnetic density harmonics, vibration noise reduction, and overall vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

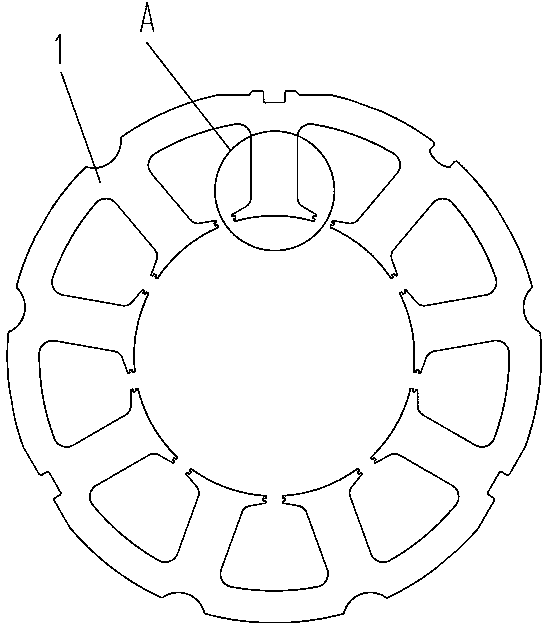

[0029] A kind of auxiliary slot stator stamping of this embodiment, such as Figure 1-2 As shown, it includes a stator punching piece 1, and an auxiliary groove 2 is respectively opened on both sides of the slot shoulder of the stator punching piece 1. By opening the auxiliary slot 2 at the slot shoulder of the stator punching plate 1, the cogging torque and torque ripple of the motor are reduced, the tangential vibration of the motor is reduced, and the sine degree of the air gap magnetic density of the motor is optimized to reduce the air gap magnetic flux density. The dense harmonic wave further reduces the radial vibration of the motor, reduces the overall vibration of the motor, and reduces vibration noise.

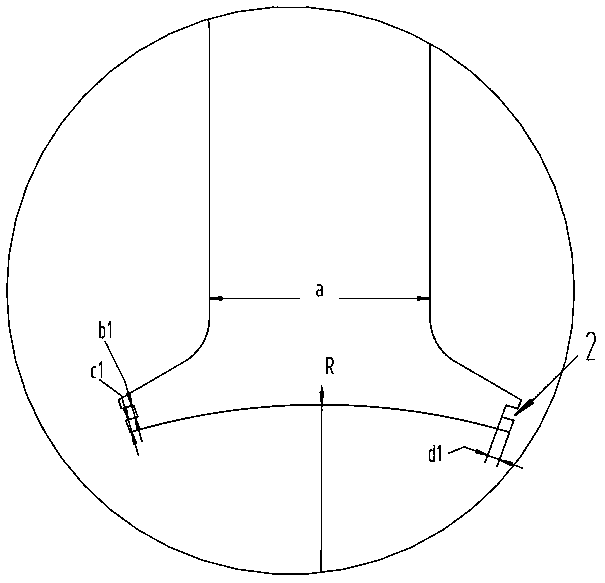

[0030] The width of the auxiliary groove 2 is b1, the depth of the auxiliary groove 2 is d1, and the distance between one side of the auxiliary groove 2 and the bottom of the slot shoulder of the stator punch 1 is c1, and the stator punch 1 The distance between adja...

Embodiment 2

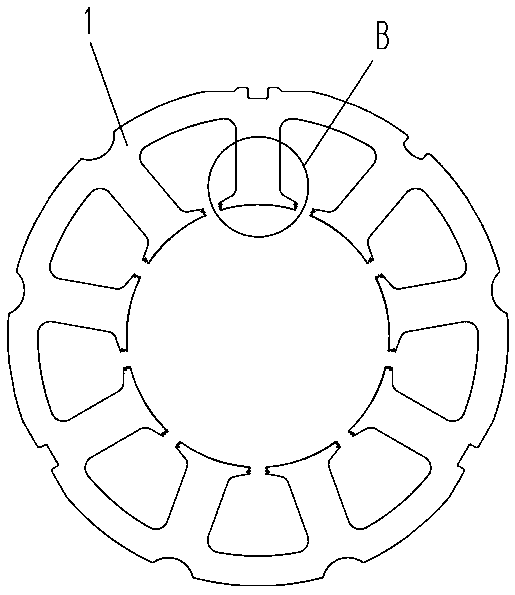

[0033] Such as Figure 3-4 As shown, the other structure of this embodiment is the same as that of Embodiment 1, the difference is that two auxiliary grooves 2 are opened on both sides of the slot shoulder of the stator punching piece 1, which are respectively the first auxiliary groove 3, The second auxiliary groove 4, the width of the first auxiliary groove 3 is b2, the depth of the first auxiliary groove 3 is d2, one side of the first auxiliary groove 3 is away from the slot shoulder of the stator punching piece 1 The distance from the bottom is c2; the width of the second auxiliary slot 4 is b3, the depth of the second auxiliary slot 4 is d3, the distance between adjacent slots of the stator punch 1 is a, and the stator punch 1 The distance between the bottom of the slot shoulder and the center of the stator punch 1 is R, where c2≥0.007*R, c2≥b2, c2≥b3, d2<0.1*a, d3<0.05*a. For the opening of two auxiliary slots 2, when the auxiliary slot 2 satisfies the above relationshi...

Embodiment 3

[0037] The other structures of this embodiment are the same as those of Embodiment 1, except that the auxiliary slot 2 is opened on the side of the slot shoulder of the stator punch 1 . The auxiliary slot 2 is set on the side of the slot shoulder of the stator punching plate 1, which can reduce the cogging torque and torque ripple of the motor, optimize the sine degree of the air gap flux density of the motor, and reduce the harmonics of the air gap flux density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com