Rotor structure and rotor assembly of surface-mounted permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and rotor structure, which is applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. It can solve the problems of large torque fluctuation, easy vibration and noise, and high cost. Achieve the effect of reducing harmonic distortion rate, reducing weight and cost, reducing cogging torque and torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

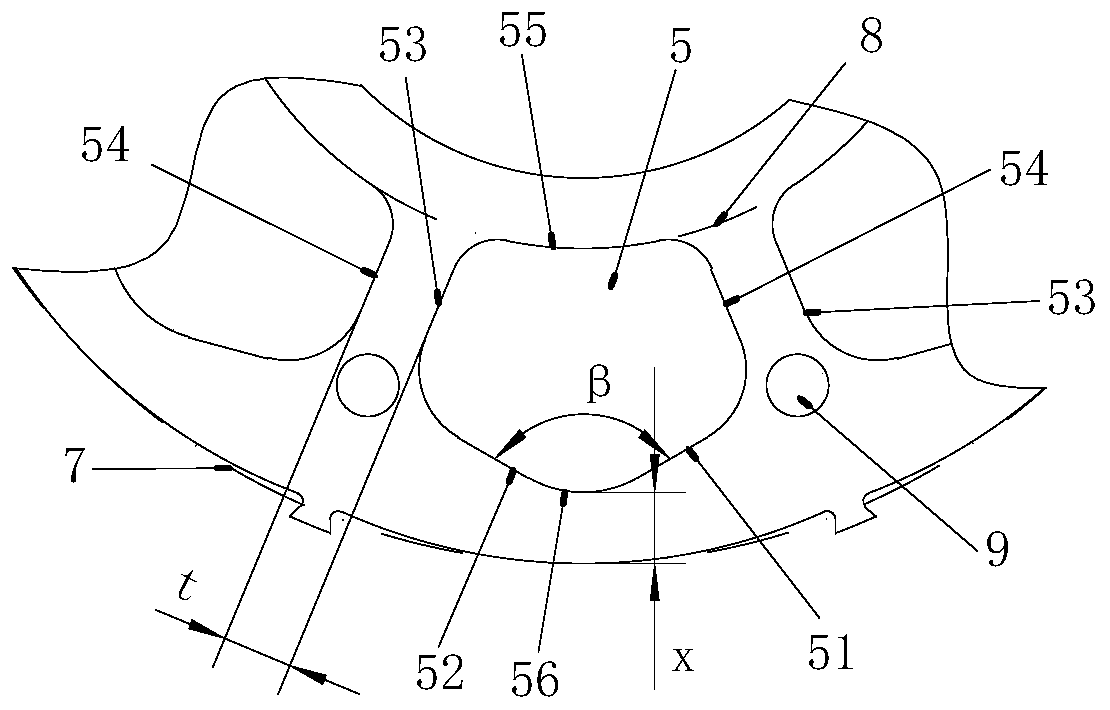

[0044] As the first embodiment of the magnetic steel bit and the magnetic steel, such as Figure 5As shown, the magnetic steel position 3 is a parallel groove, and the groove edges 31 on both sides of the magnetic steel position 3 are parallel to each other, as Image 6 As shown, the magnetic steel 2 is a parallel magnetic steel, and the two side lines 21 of the magnetic steel 2 are parallel to each other.

[0045] As the second embodiment of the magnetic steel bit and the magnetic steel, such as Figure 7 As shown, the magnetic steel position 3 is a dovetail groove, and the straight lines where the groove edges 32 on both sides of the magnetic steel position 3 intersect each other, and the angle formed is γ, as Figure 8 As shown, the magnetic steel 2 is a dovetail type magnetic steel, the straight lines where the side lines 22 on both sides of the magnetic steel 2 intersect each other, and the angle formed is γ1, γ=γ1, and the angle between γ and γ1 can be set according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com