Lamp pole bending equipment

A technology for equipment and light poles, which is applied in the field of light pole bending equipment, can solve the problems of steel plate indentation and bending, inability to guarantee, etc., and achieve the effect of avoiding defective products and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

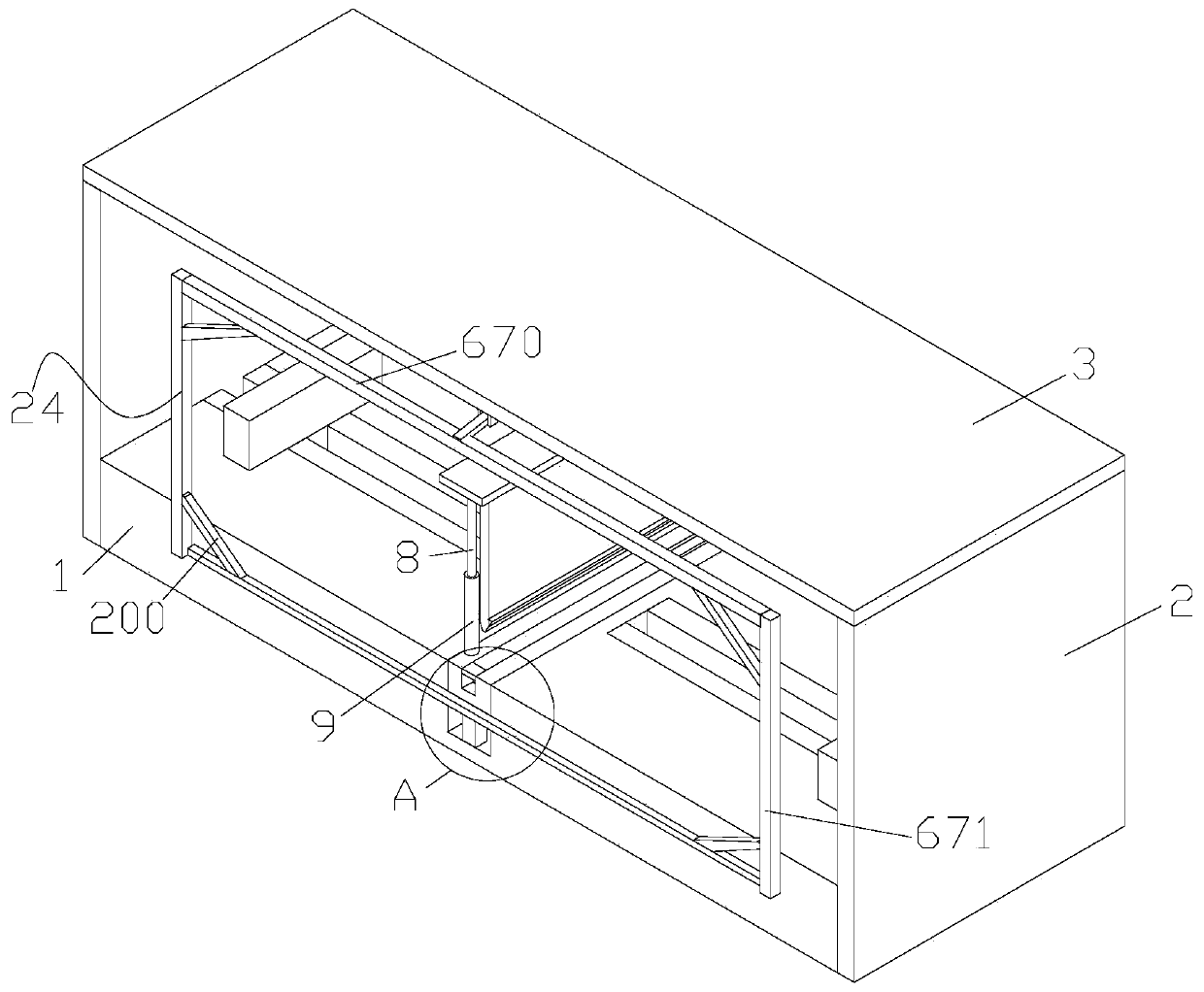

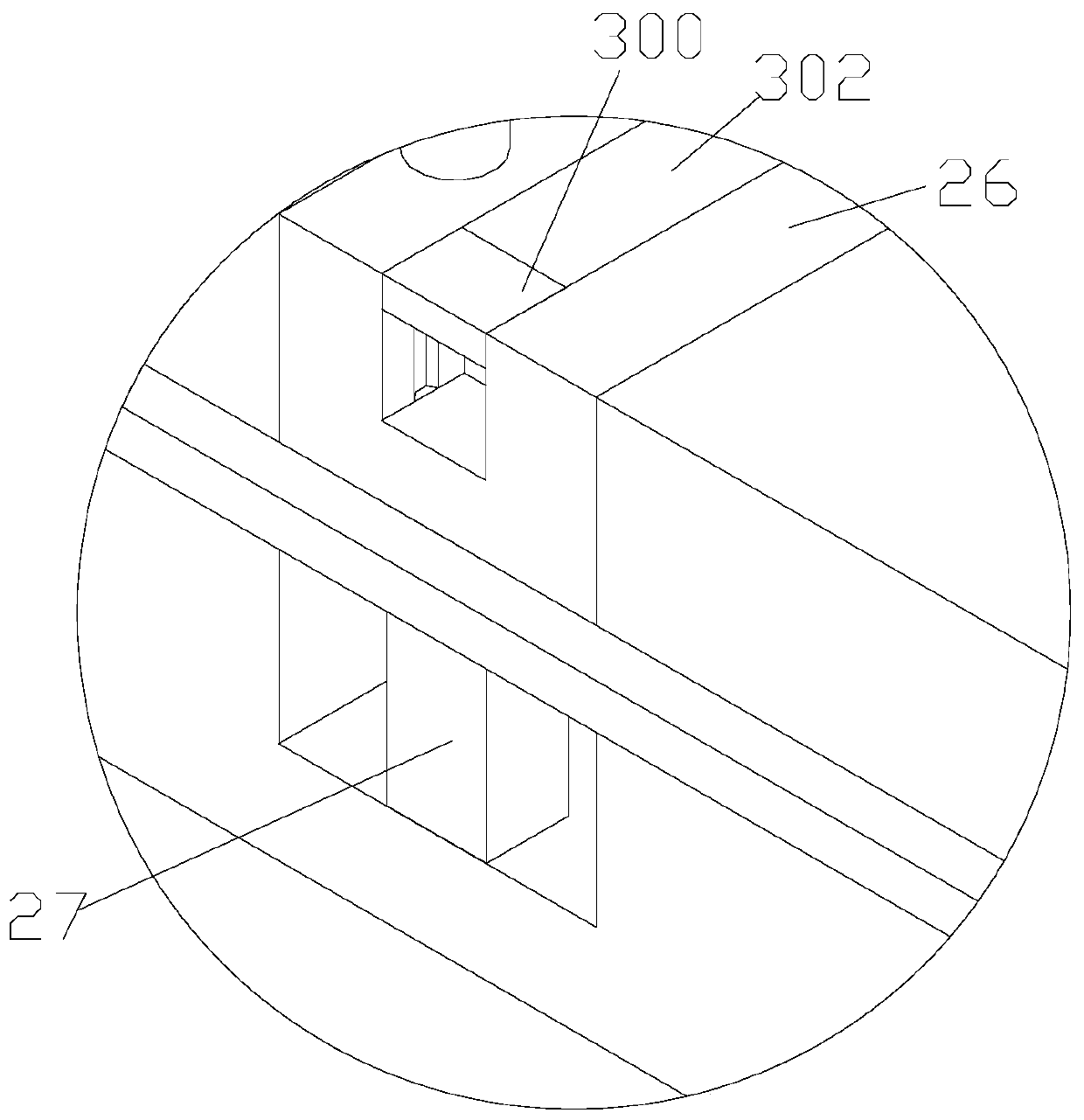

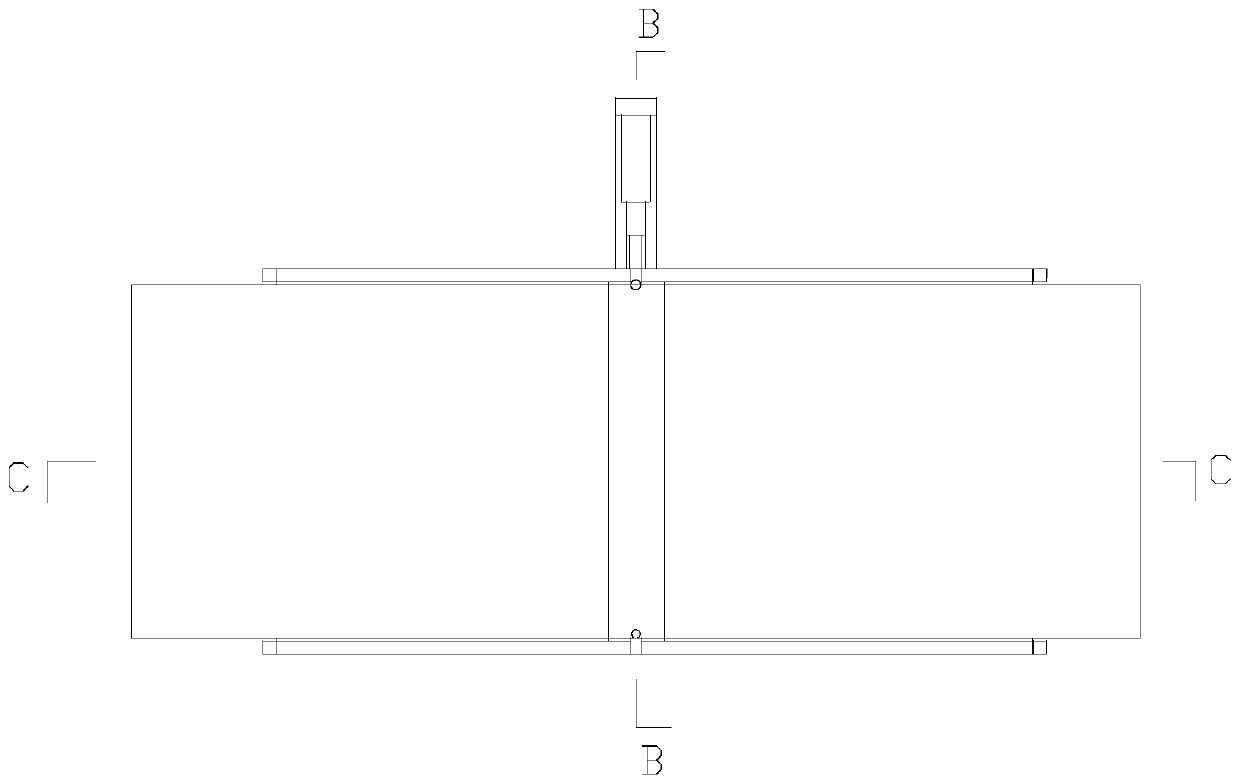

[0021] like Figure 1-6 As shown, in order to achieve the above purpose, the present invention adopts the following technical solutions: a light pole bending equipment, including a machine base 1, two vertical plates 2 fixedly arranged on the left and right end faces of the machine base 1, fixedly arranged on the two vertical plates 2 The top plate 3 on the upper end surface, the groove arranged on the upper surface of the machine base 1, the two stroke grooves respectively arranged on the left and right sides of the groove, the rodless cylinder 4 fixedly arranged in the stroke groove, the rodless cylinder 4 fixedly arranged at the output end of the rodless cylinder 4 The mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap