Secondary cooling steam white eliminating device for continuous casting

A steam and continuous casting technology, applied in the field of metallurgy, can solve the problems of high investment and operating costs and few cases, and achieve the effects of improving whitening effect and efficiency, easy operation, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

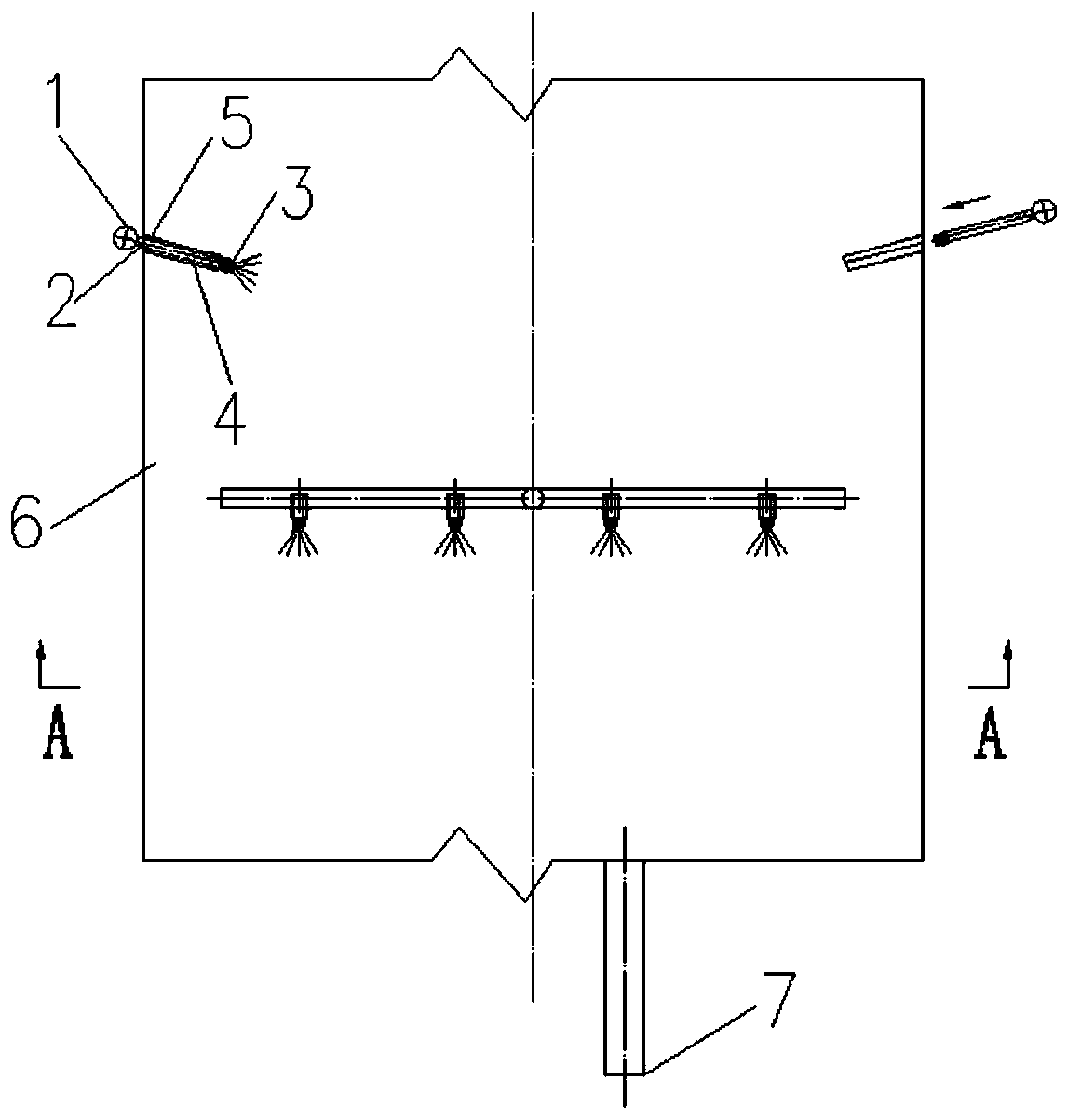

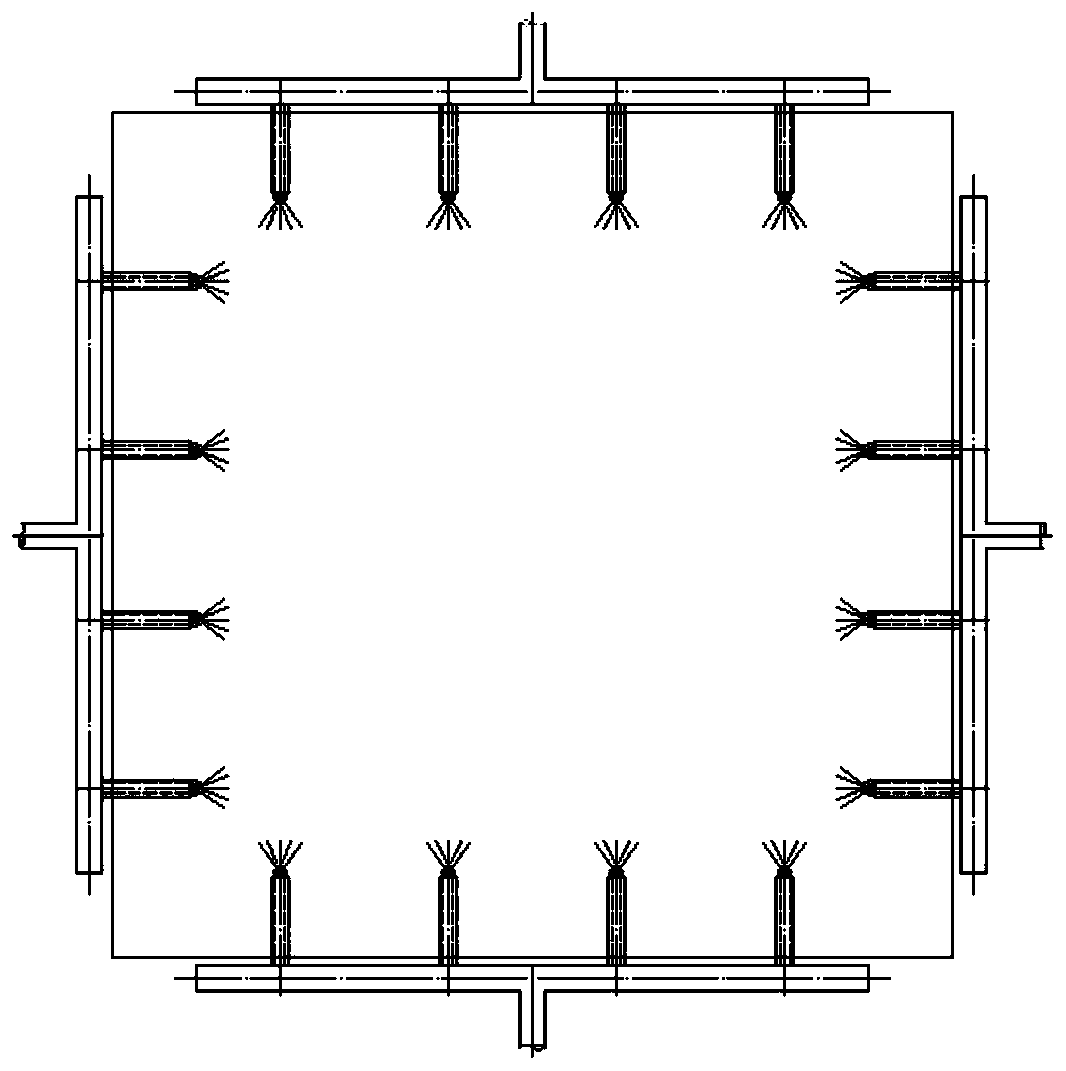

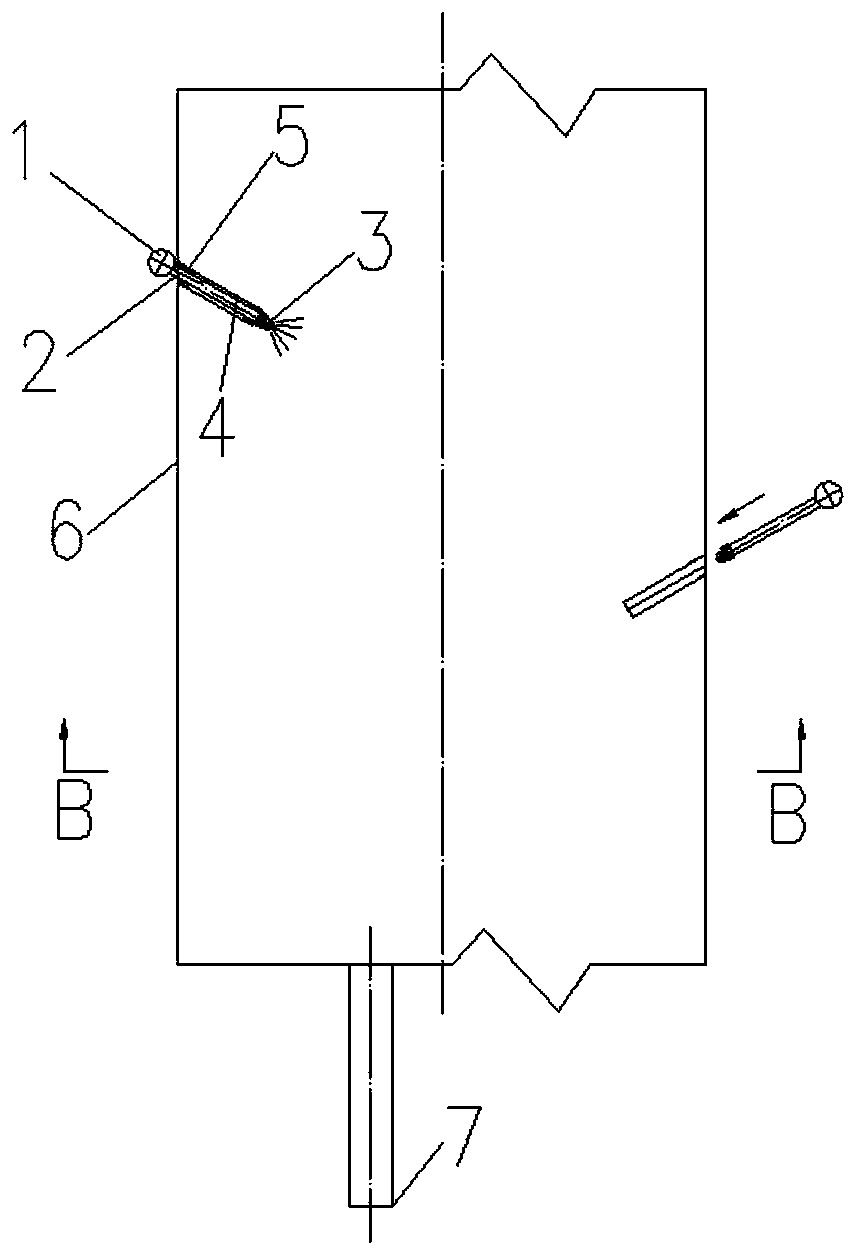

[0020] A large amount of water vapor will be generated when the slab is cooled in the secondary cooling room of the continuous casting workshop, and the fan is often used to discharge it directly through the steam discharge main pipe 6 . The steam discharge main pipe 6 of the continuous casting workshop is arranged above the continuous casting workshop, one end of which communicates with the interior of the continuous casting workshop, and the other end communicates with the inlet of the fan.

[0021] Such as figure 1 with image 3 As shown, a secondary cooling steam whitening device for continuous casting includes a water supply pipe assembly, and several high-pressure nozzles 3 communicated with the water supply pipe assembly; the high-pressure nozzle 3 is installed on the inner wall of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap