Automatic assembly welding machine for cross beam

A welding machine, automatic technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large space occupation, high labor cost, high labor intensity, etc., and achieve high production efficiency and labor load. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the embodiment the present invention is described in detail, it is necessary to point out that this embodiment is only used to further explain the present invention, can not be interpreted as the limitation to the scope of protection of the present invention, those skilled in the art can make according to the content of the above-mentioned invention Some non-essential improvements and adjustments.

[0025] The specific embodiment of the present invention is:

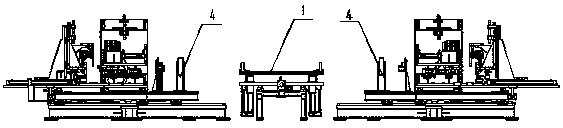

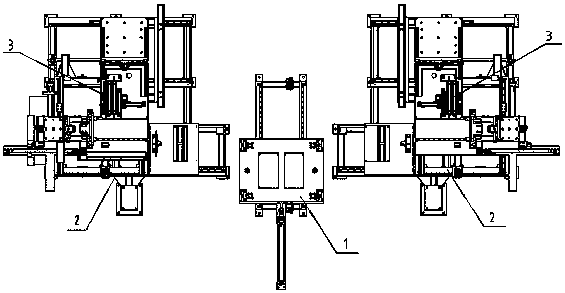

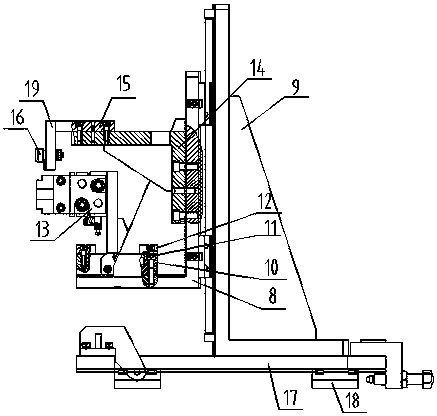

[0026] An automatic beam assembly welding machine, comprising a trolley mechanism 1, two equipment main bodies 2, a gripper mechanism, an automatic feeding mechanism, a flange hopper 3, a roller frame 4, a welding module and a main control board, the trolley mechanism 1 Set between the two equipment main bodies 2, the trolley mechanism 1 and the equipment main body 2 are respectively fixed on the foundation by pouring cement, and the flange silo 3 and the roller frame 4 are fixed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com