An automatic turning thread rolling machine

A technology of turning thread rolling machine and thread rolling machine, which is applied to manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of low processing efficiency of metal rods, and achieve the effect of ensuring smooth movement and avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

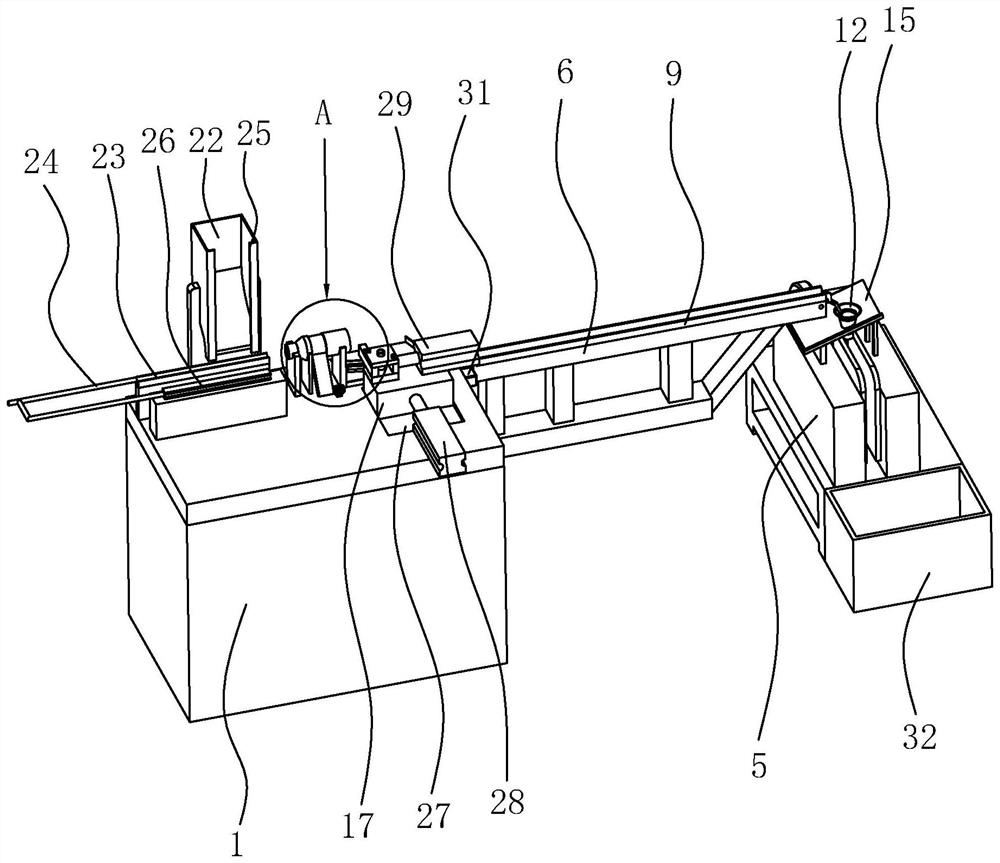

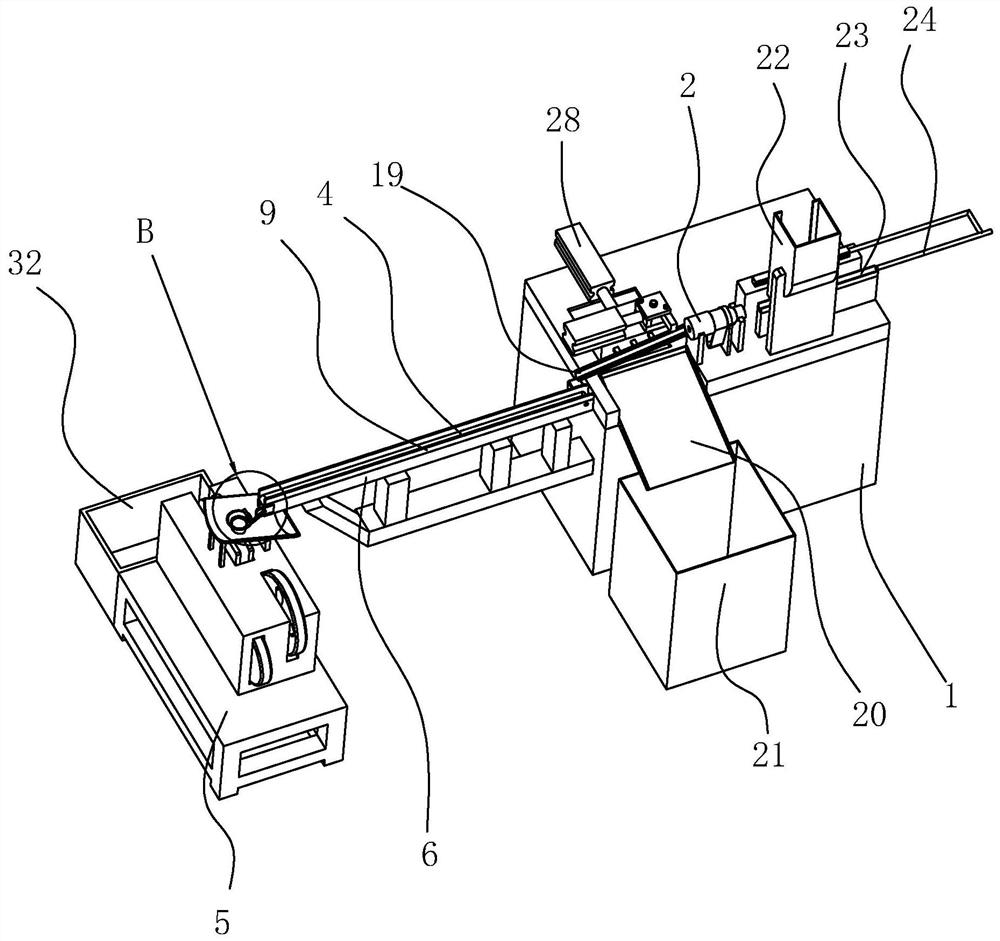

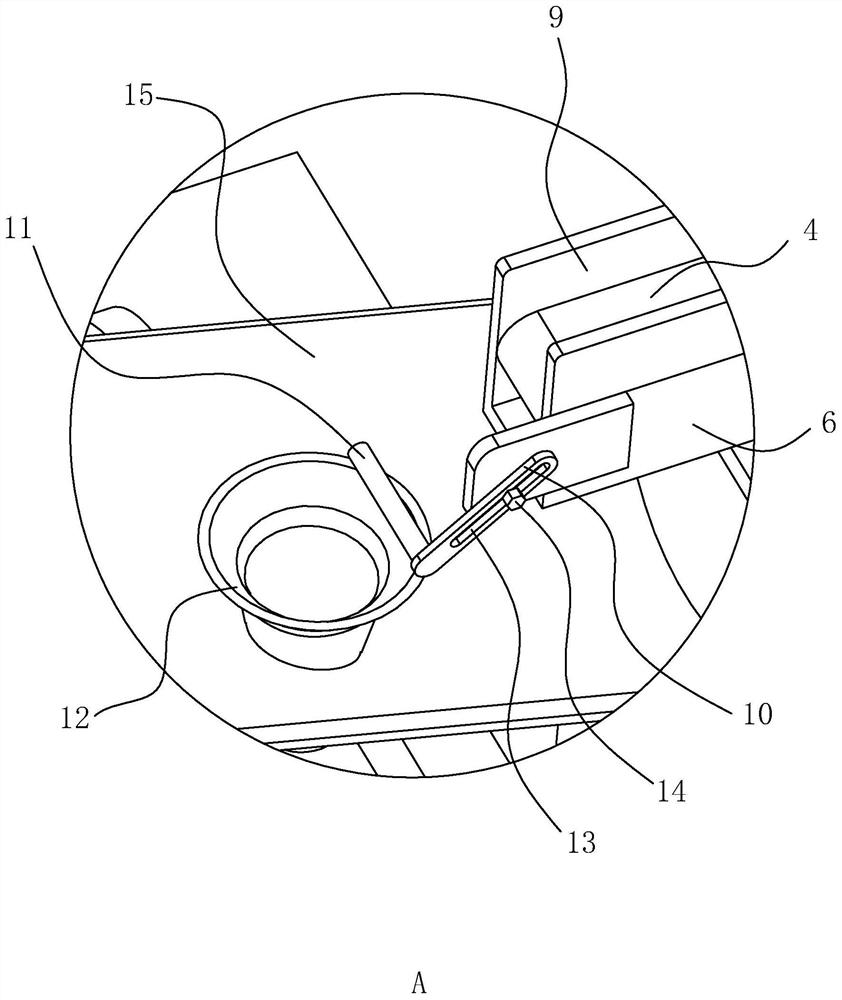

[0040] refer to figure 1 , is a kind of automatic turning thread rolling machine disclosed by the present invention, comprises machine base 1, is provided with feeding device, turning device, conveying transposition device, thread rolling device and unloading device successively on machine base 1; Feeding device comprises The storage rack 22 with openings at the upper and lower ends, the storage rack 22 is cuboid and vertically erected and fixed on the upper end surface of the machine base 1, the thickness of the storage rack 22 is in a trend of decreasing gradually from top to bottom, the storage rack The opening at the lower end of the 22 can only accommodate a metal rod to be processed. The machine base 1 is provided with a slide rail 23 with a U-shaped cross section just below the opening at the lower end of the storage rack 22. The slide rail 23 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com