Belt drive self-propelled millet combine harvester

A combine harvester, self-propelled technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems affecting the economic development of millet producing areas, lack of millet harvesting machinery, high labor intensity, etc. Good performance, low loss rate, and the effect of reducing breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

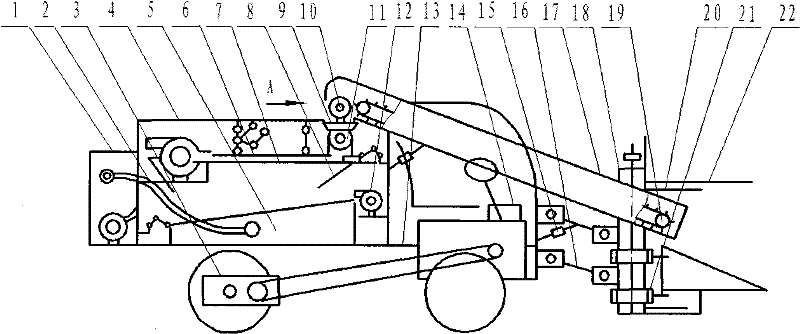

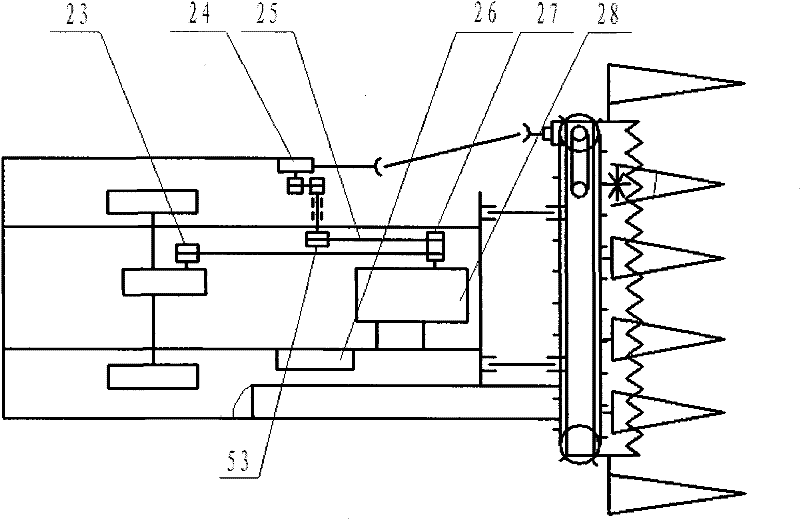

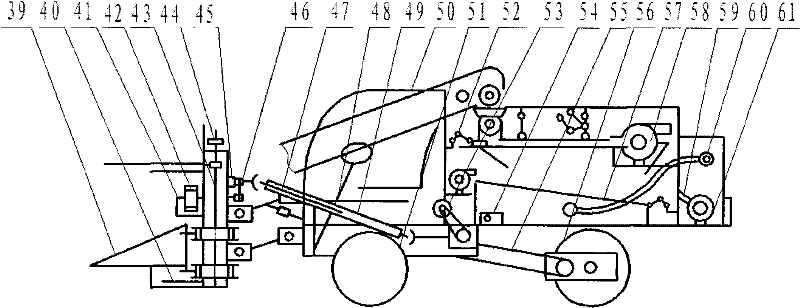

[0033] A belt-driven self-propelled millet combine harvester, as shown in the accompanying drawings, consists of a granary 1, a grain suction pipe 2, a main engine gearbox 3, a frame 4, a grain collection bin 5, a movable grain rubbing board combination 6, a fixed Grain rubbing board 7, grain gathering board 8, scion bucket 9, scion bucket fan 10, rubbing and cutting roller combination 11, trash removal fan 12, vehicle frame 13, harvesting control mechanism combination 14, oil cylinder and oil pipe 15, lifting device 16, conveying Groove 17, cutting platform frame 18, conveying trough pulley 19, corn ear cutter combination 20, grain stalk conveying wheel assembly 21, ear guide 22, host clutch pulley 23, reversing gear box combination 24, transmission belt combination 25, Battery 26, engine pulley 27, engine 28, harvesting clutch belt 29, belt A30, belt B31, belt C32, belt D33, belt E34, belt F35, belt G36, belt H37, belt I38, grain lifter 39, grain stalk cutter Knife combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com