Anti-crushing loosening device for discharging of tobacco storage cabinet

A technology for storage cabinets and tobacco, which is applied in the directions of loading/unloading, transportation and packaging, and conveyors. It can solve the problems of increased filament consumption, affecting the inner quality of cigarettes, and repeated stirring of materials arranged in multiple layers of rollers. The effect of whole shred rate and filling value, reduction of tobacco crushing rate, and high rake loosening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

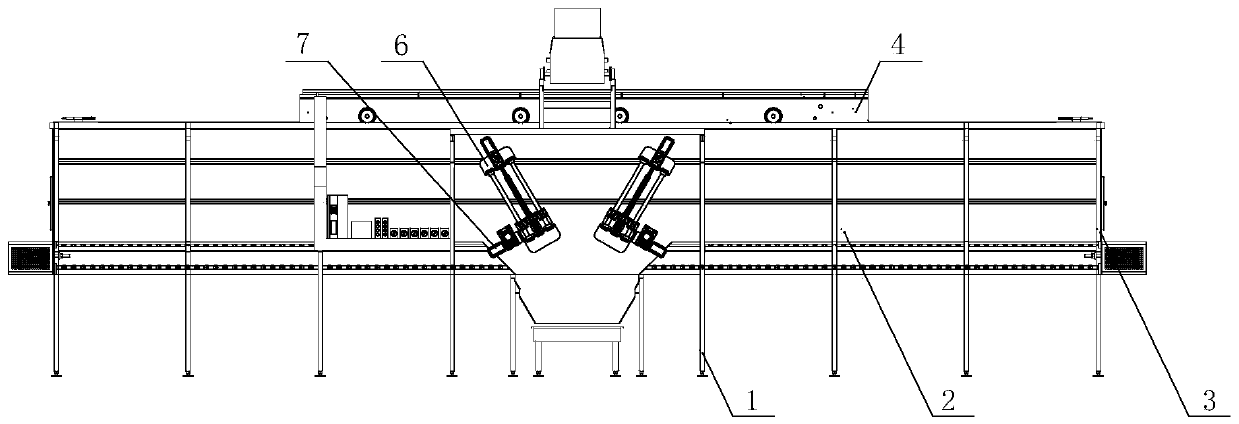

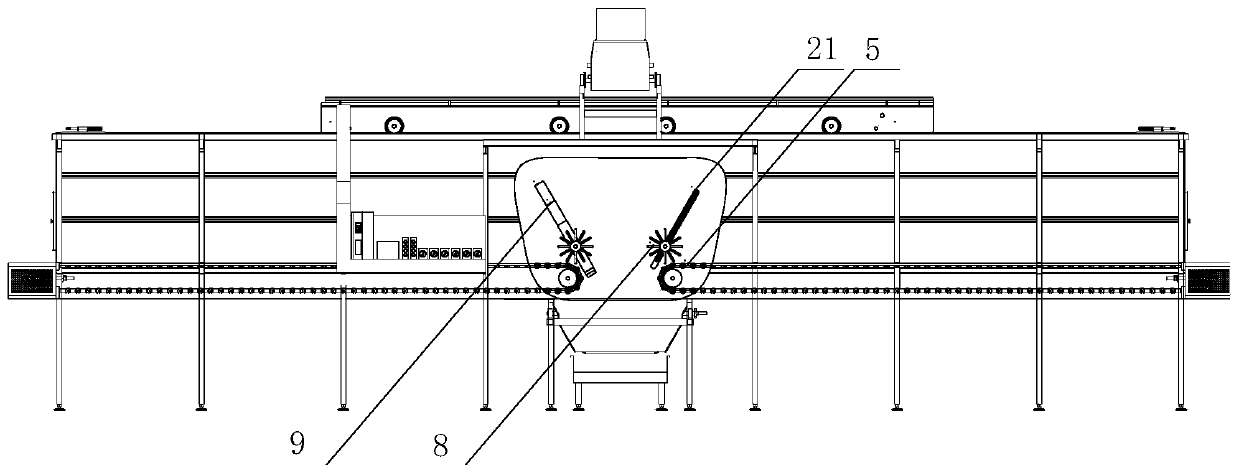

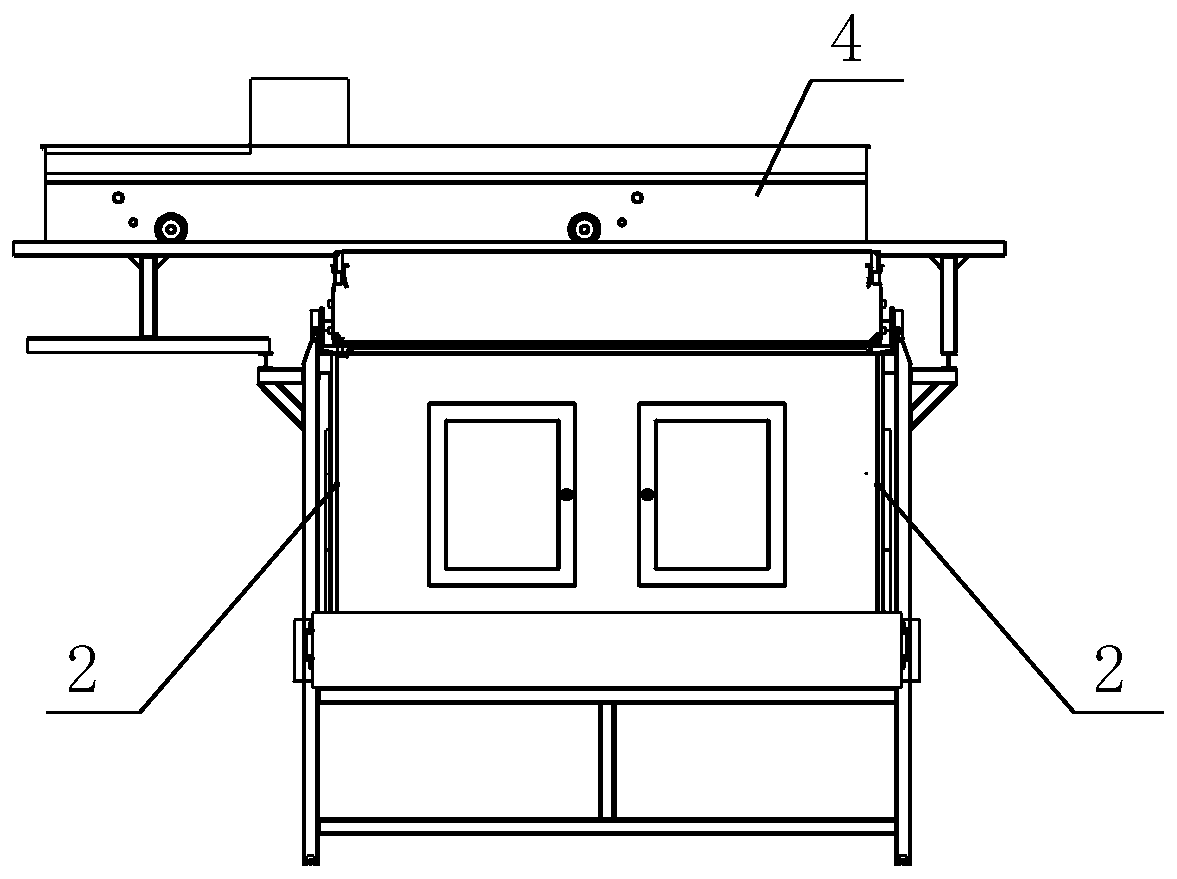

[0022] Such as Figure 1-3 As shown, the storage cabinet includes a column 1, two left and right side panels 2, a discharge opening baffle and a tail baffle 3, forming a trough-shaped cabinet. The material spreading vehicle 4 puts the material on the belt of the material spreading vehicle, and the material spreading vehicle 4 directs the motor and the reducer through electric control to make it reciprocate on the guide rail of the storage cabinet opening from the head to the tail of the storage cabinet. The materials are spread evenly layer by layer on the material bearing belt 5 at the bottom, and this is repeated until the material in the storage cabinet reaches the set storage thickness; The feed port is provided with a raking mechanism 8.

[0023] When discharging, start the conveying bottom belt deceleration motor and raking licker-in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com