High-specific-volume and high-performance corrosion foil system

A high-performance, foil-corrosion technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of uneven pores, tumbling and boiling of the bath solution, and affecting material transmission, etc., to achieve high hole formation efficiency, uniform hole formation, and improved corrosion ratio Content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

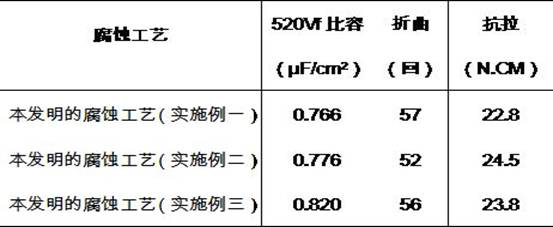

Embodiment 1

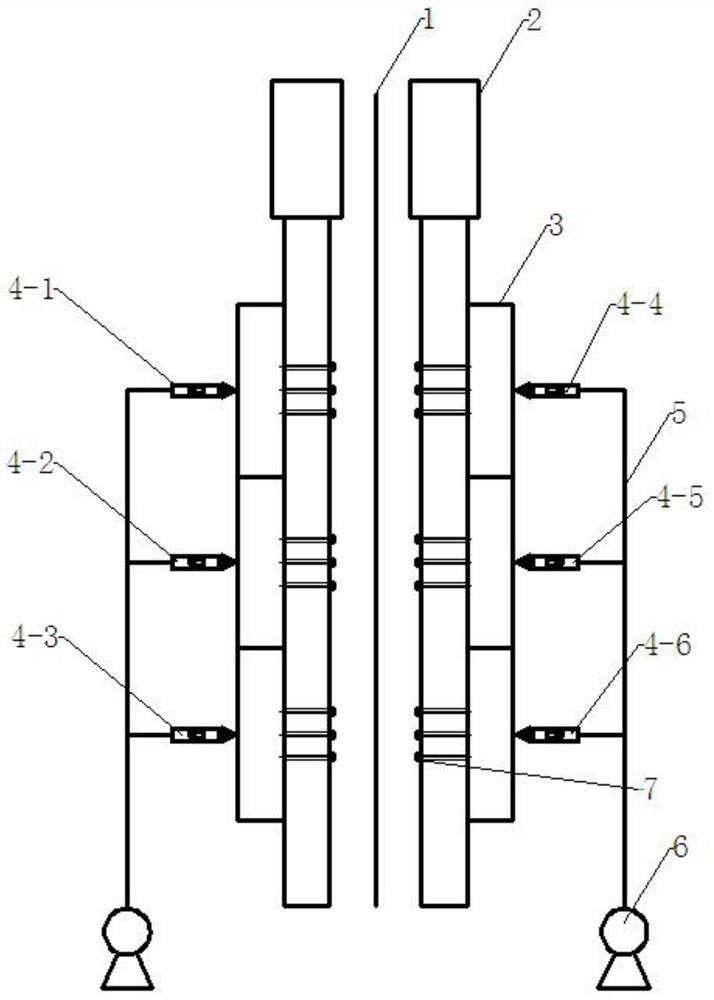

[0019] Please refer to figure 1 , a high specific volume and high performance corroded foil system, the system includes symmetrically arranged graphite pole plates 2, an aluminum foil 1 is arranged between the graphite pole plates, and the opposite faces of the two graphite pole plates are symmetrically arranged. There are several installation holes, nozzles 7 are installed in the installation holes, three hydraulic chambers 3 are installed on the opposite sides of the two graphite plates, the three hydraulic chambers correspond to the same number of nozzles, and the three hydraulic chambers correspond to the same number of nozzles. The hydraulic chambers are connected to the acid and alkali resistant magnetic pump 6 through a liquid supply pipeline 5, and the hydraulic chambers and the liquid supply pipelines are connected through a rotameter.

[0020] The rotameter includes a rotameter (1) 4-1, a rotameter (2) 4-2, a rotameter (3) 4-3, a rotameter (4) 4-4, a rotameter ( 5) ...

Embodiment 2

[0027] (1) Pretreatment: Place the electronic aluminum foil in a 20wt% sulfuric acid 1wt% hydrochloric acid solution at a temperature of 60°C-65°C for 60 seconds.

[0028] (2) First-level corrosion pores: After cleaning the pretreated aluminum foil, it is energized and corroded in a mixed solution containing 2.0wt% hydrochloric acid, 40wt% sulfuric acid and 1.0wt% aluminum ions at a temperature of 70°C, and the current density is 0.6 A / cm2, the time is 120 seconds, and flowmeters 1 and 4 are 4m³ / h;

[0029] Flow meters 2 and 4 are 4m³ / h; flow meters 3 and 6 are 4m³ / h.

[0030] (3) Secondary corrosion hole expansion: the cleaned perforated foil is energized in a mixed solution containing 10wt% nitric acid, 0.1g / L polypropylene alcohol (10000) and 4.0wt% aluminum ions at a temperature of 69 ° C and subjected to DC corrosion , current density 0.15A / cm2, time 800 seconds.

[0031] (4) Post-treatment: soak the reamed foil after cleaning for 80 seconds in a solution containing 5wt...

Embodiment 3

[0033] (1) Pretreatment: Place the electronic aluminum foil in a 20wt% sulfuric acid 1wt% hydrochloric acid solution at a temperature of 60°C-65°C for 60 seconds.

[0034] (2) First-level corrosion pores: After cleaning the pretreated aluminum foil, it is energized and corroded in a mixed solution containing 2.0wt% hydrochloric acid, 40wt% sulfuric acid and 1.0wt% aluminum ions at a temperature of 70 ° C, and the current density is 0.6 A / cm2, the time is 120 seconds, and flowmeters 1 and 4 are 5m³ / h;

[0035] Flow meters 2 and 5 are 4m³ / h; flow meters 3 and 6 are 3m³ / h

[0036] (3) Secondary corrosion expansion: the cleaned perforated foil is energized in a mixed solution containing 10wt% nitric acid, 0.1g / L polypropylene alcohol (10000) and 4.0wt% aluminum ions at a temperature of 69°C , current density 0.15A / cm2, time 800 seconds.

[0037] (4) Post-treatment: soak the reamed foil after cleaning for 80 seconds in a solution containing 5wt% nitric acid at a temperature of 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com