A kind of preparation method of electrode foil for low-voltage aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and electrode foils, which is applied in the manufacture of electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of not being able to achieve current efficiency, and achieve the effects of improving pore efficiency, reducing dissolution, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] According to the embodiment provided by the present invention, the preparation method of the electrode foil for low-voltage aluminum electrolytic capacitors includes:

[0027] 1) Pre-treatment: soak the aluminum foil in an aqueous solution of 0.1-1 wt.% sodium hydroxide at 30-60°C for 30-90 seconds, and then wash it with water;

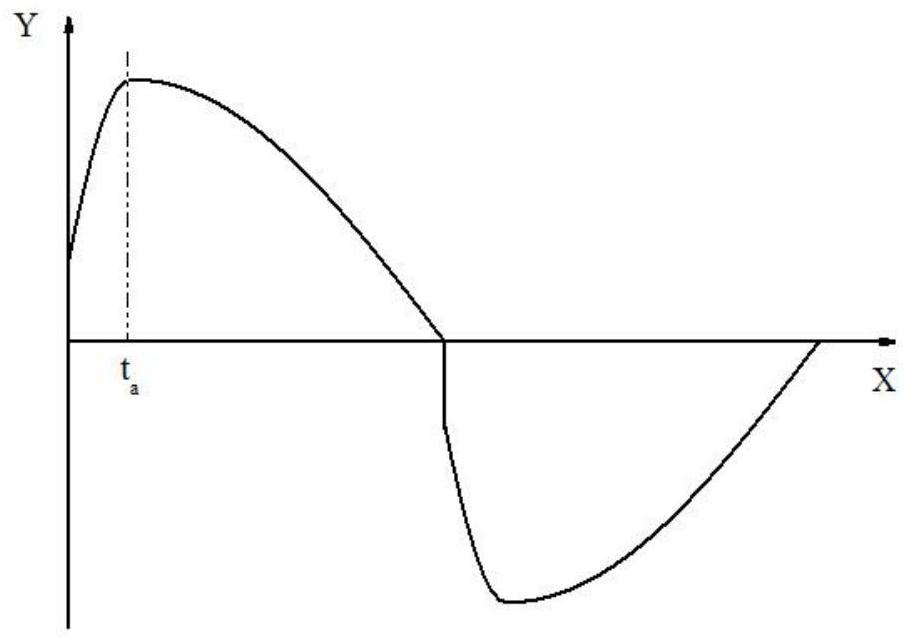

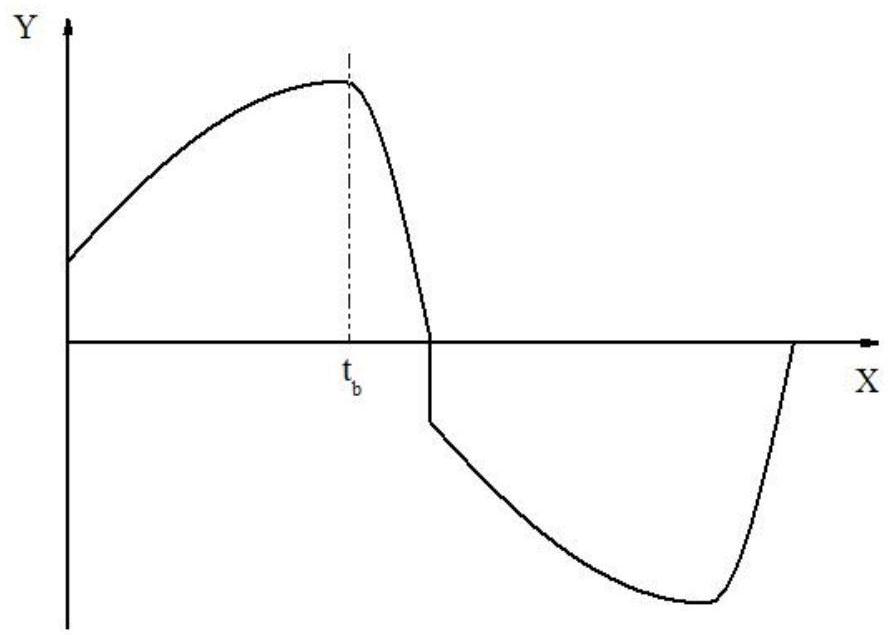

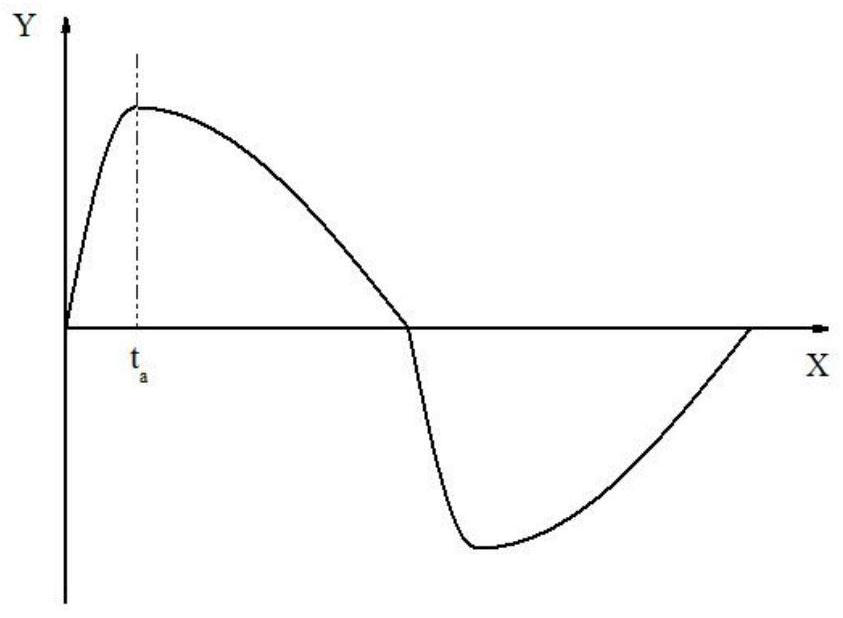

[0028] 2) Pore corrosion: put the pretreated aluminum foil in an aqueous solution containing 5-15wt.% hydrochloric acid, 0.01-0.1wt.% sulfuric acid and 0.1-2.0wt.% aluminum chloride solution at 10-50°C Pore corrosion, the current density is 0.1~0.5A / cm 2 , the power-on time is 10-50 seconds, the frequency is 10-40 Hz, the power-on waveform used in the hole corrosion is an offset sine wave whose initial current is not zero and the value of the peak deviation from zero is 0-0.25T, and The peak deviates from the zero point value is not the endpoint value, and then washed;

[0029] 3) Intermediate treatment: put the aluminum foil corroded by th...

Embodiment 1

[0113] 1) Pretreatment: Soak the aluminum foil in an aqueous solution of 1 wt.% sodium hydroxide at 40°C for 80 seconds, then wash it with water at room temperature for 60 seconds;

[0114] 2) Pore corrosion: place the aluminum foil after the above pretreatment in an aqueous solution containing 6wt.% hydrochloric acid, 0.03wt.% sulfuric acid and 1wt% aluminum chloride at 50°C, and the current density is 0.5A / cm 2 , the power-on time is 20 seconds, the frequency is 20Hz, the power-on waveform is an offset sine wave whose current starting point is not zero and the peak deviates from zero with a value of 0.05T, and then washed with water at room temperature for 120 seconds;

[0115] 3) Intermediate treatment: put the above-mentioned aluminum foil corroded by the hole layout in an aqueous solution of potassium dihydrogen phosphate containing 2wt.% at 60°C for intermediate treatment, the treatment time is 80 seconds, and then wash with water at room temperature for 100 seconds;

...

Embodiment 2

[0122] 1) Pretreatment: Soak the aluminum foil in an aqueous solution of 0.4wt.% sodium hydroxide at 60°C for 40 seconds, then wash it with water at room temperature for 60 seconds;

[0123] 2) Pore corrosion: put the aluminum foil after the above pretreatment in 30°C containing 10wt.% hydrochloric acid, 0.06wt.% sulfuric acid and 0.6wt.% aluminum trichloride aqueous solution, and the current density is 0.3A / cm 2 , the power-on time is 40 seconds, the frequency is 30Hz, the power-on waveform is an offset sine wave whose current starting point is not zero and the peak deviates from zero with a value of 0.10T, and then washed with water at room temperature for 180 seconds;

[0124] 3) Medium treatment: put the above-mentioned aluminum foil corroded by the hole layout in an aqueous solution of potassium dihydrogen phosphate containing 6wt.% at 80°C for medium treatment, the treatment time is 80 seconds, and then wash with water at room temperature for 120 seconds;

[0125] 4) De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com