A Corrosion Pore Device for Improving Corrosion Specific Volume of Aluminum Foil

An aluminum foil and specific volume technology, which is applied in the field of perforation devices, can solve the problems of uneven perforation and low perforation efficiency, and achieves the effects of uniform perforation, high perforation efficiency, and prevention of blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

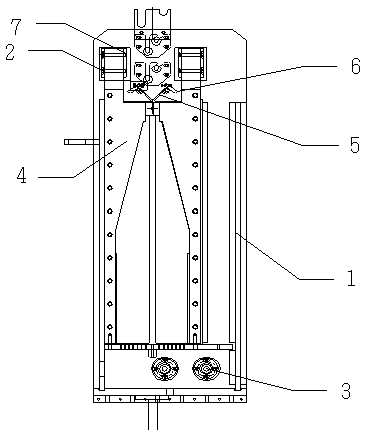

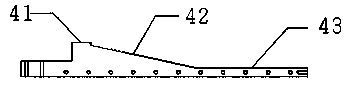

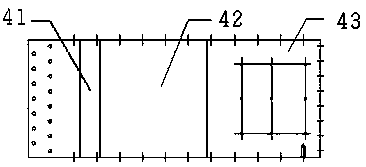

[0022] Such as figure 1 As shown in the figure, there is an corrosion-perforating device for improving the corrosion specific volume of aluminum foil. The aluminum foil is set on the roll body, including the corrosion tank 1, the foil clamping device and the heat dissipation device 2; the bottom of the corrosion tank 1 is provided with a liquid chamber 3, and the corrosion tank Two electrodes 4 are arranged symmetrically inside the body 1, an corrosive solution is arranged in the corrosion tank body 1, the foil clamping device is arranged above the corrosive liquid, the cooling device 2 is arranged above the foil clamping device, and a power supply is also included. Connect the roller body and the electrode. The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com