Manufacturing method of electrode foil for aluminum electrolytic capacitor and electrode foil

A technology for aluminum electrolytic capacitors and a manufacturing method, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of short hole length, no contribution to the specific volume of the corroded foil, etc., and achieves thinning of thickness, reduction of ineffective dissolution, and distribution of pores on the surface. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The manufacturing method of the electrode foil for aluminum electrolytic capacitor provided in this embodiment comprises the following steps:

[0038] (1) Pretreatment step: Soak the electronic aluminum foil in 40°C and 2% sodium hydroxide aqueous solution by mass for 80 seconds, then wash the aluminum foil with pure water at room temperature to obtain a pore corrosion treatment. aluminum foil;

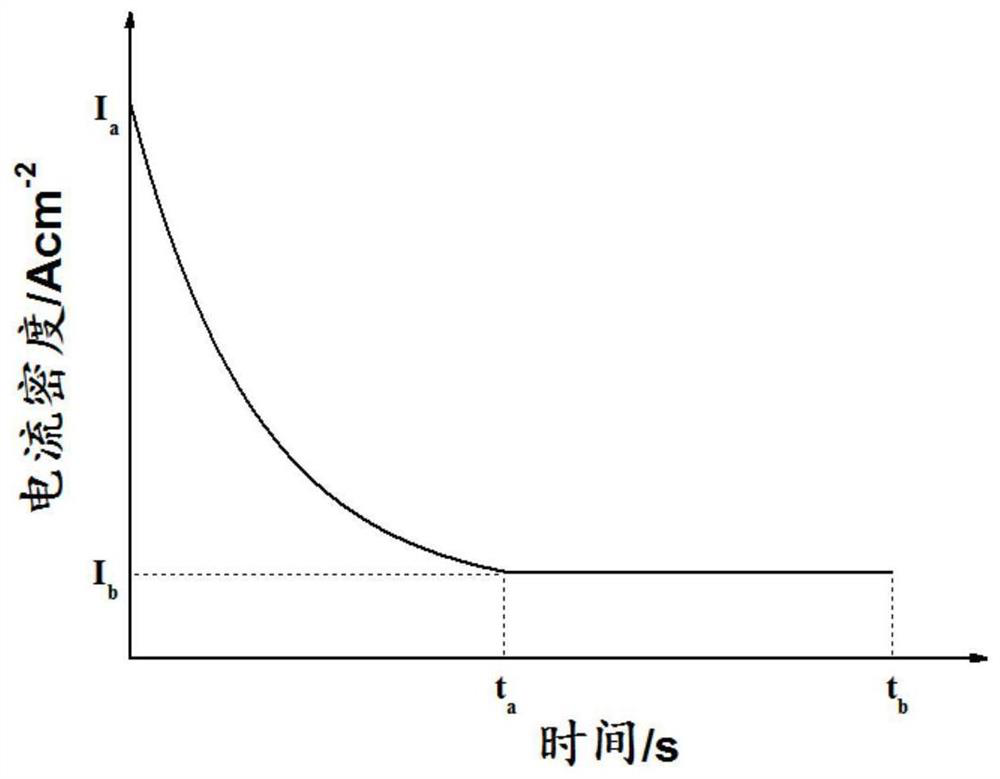

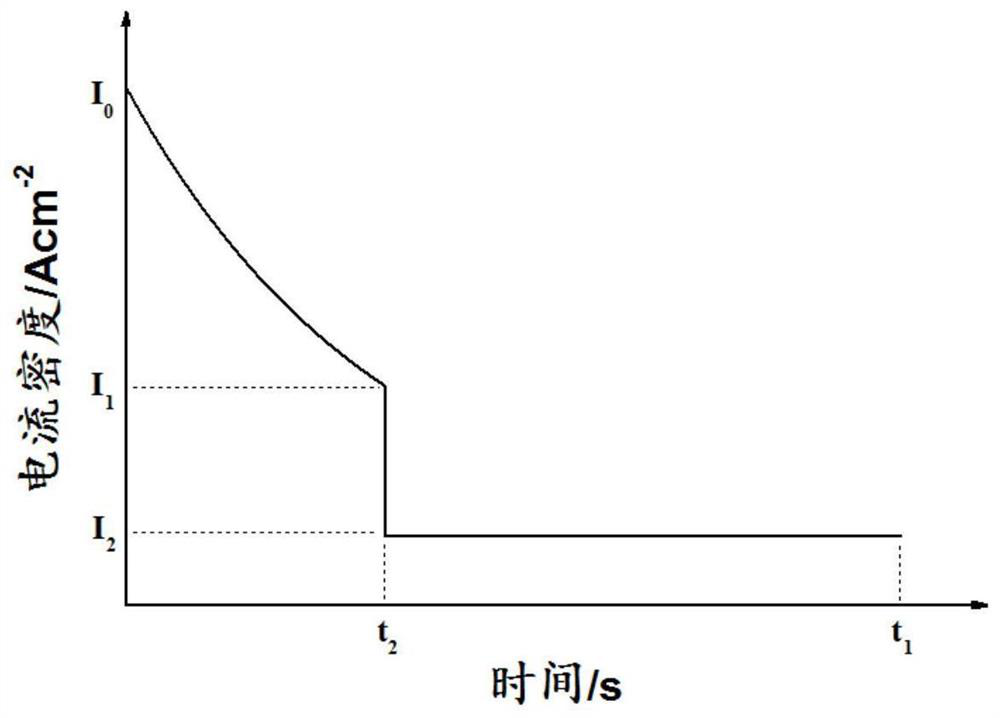

[0039] (2) Pore corrosion treatment step: place the pretreated aluminum foil in an aqueous solution containing hydrochloric acid, sulfuric acid and aluminum ions at a temperature of 75°C for energized porosity corrosion. The aqueous solution containing hydrochloric acid, sulfuric acid and aluminum ions is used The mass percent contents of hydrochloric acid, sulfuric acid and aluminum ions in the medium are 3.5%, 28%, and 1% respectively, and the energized current curve adopted in the porosity corrosion treatment is the attenuation mutation current curve, and the waveform diagra...

Embodiment 2

[0045] The manufacturing method of the electrode foil for aluminum electrolytic capacitor provided in this embodiment comprises the following steps:

[0046] (1) Pretreatment step: soak the electronic aluminum foil in 50°C and 1% sodium hydroxide aqueous solution by mass for 70 seconds, and then wash the aluminum foil with pure water at room temperature to obtain a pore corrosion treatment. aluminum foil;

[0047] (2) Pore corrosion treatment step: place the aluminum foil after pretreatment in an aqueous solution containing hydrochloric acid, sulfuric acid and aluminum ions at a temperature of 70°C for energized porosity corrosion, and the aqueous solution containing hydrochloric acid, sulfuric acid and aluminum ions is used The mass percent contents of hydrochloric acid, sulfuric acid and aluminum ions in the medium were 4%, 35%, and 0.8% respectively, and the energized current curve adopted in the porosity corrosion treatment was the attenuation mutation current curve, and t...

Embodiment 3

[0053] The manufacturing method of the electrode foil for aluminum electrolytic capacitor provided in this embodiment comprises the following steps:

[0054] (1) Pretreatment step: Soak the electronic aluminum foil in 60°C and 0.6% by mass sodium hydroxide aqueous solution for 90 seconds, then wash the aluminum foil with pure water at room temperature to obtain a pore corrosion treatment. aluminum foil;

[0055] (2) Pore corrosion treatment step: place the pretreated aluminum foil in an aqueous solution containing hydrochloric acid, sulfuric acid and aluminum ions at a temperature of 68°C for energized porosity corrosion. The aqueous solution containing hydrochloric acid, sulfuric acid and aluminum ions is used The mass percent contents of hydrochloric acid, sulfuric acid and aluminum ions in the medium were 5%, 40%, and 1% respectively, and the energized current curve adopted in the porosity corrosion treatment was the attenuation mutation current curve, and the waveform diag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com