Friction winding machine for super-wide sheets

A technology of winding machine and sheet material, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., which can solve the problems that the inflatable shaft cannot be rewound, the edge of the sheet is easy to crack, and the hardness is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

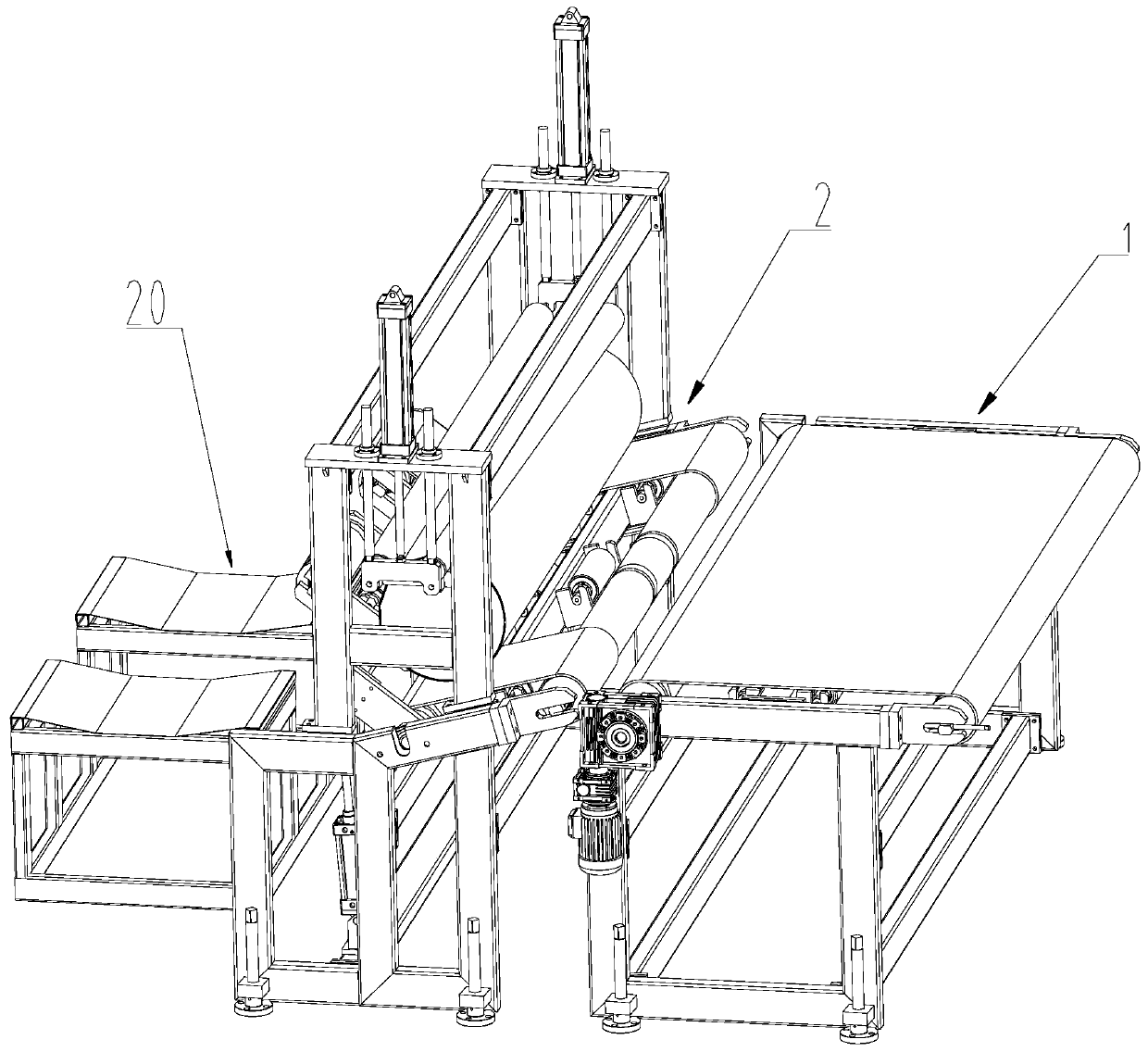

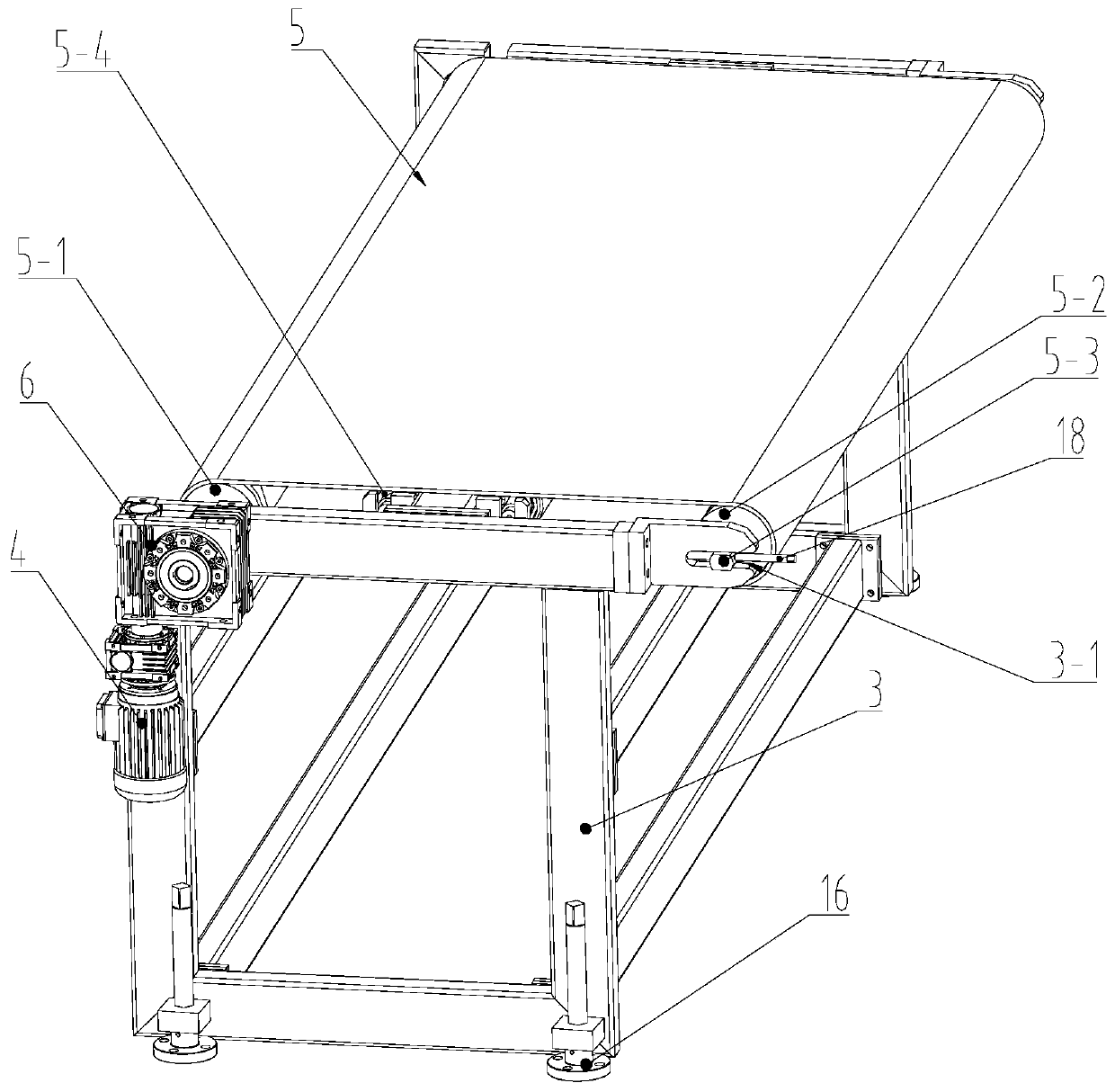

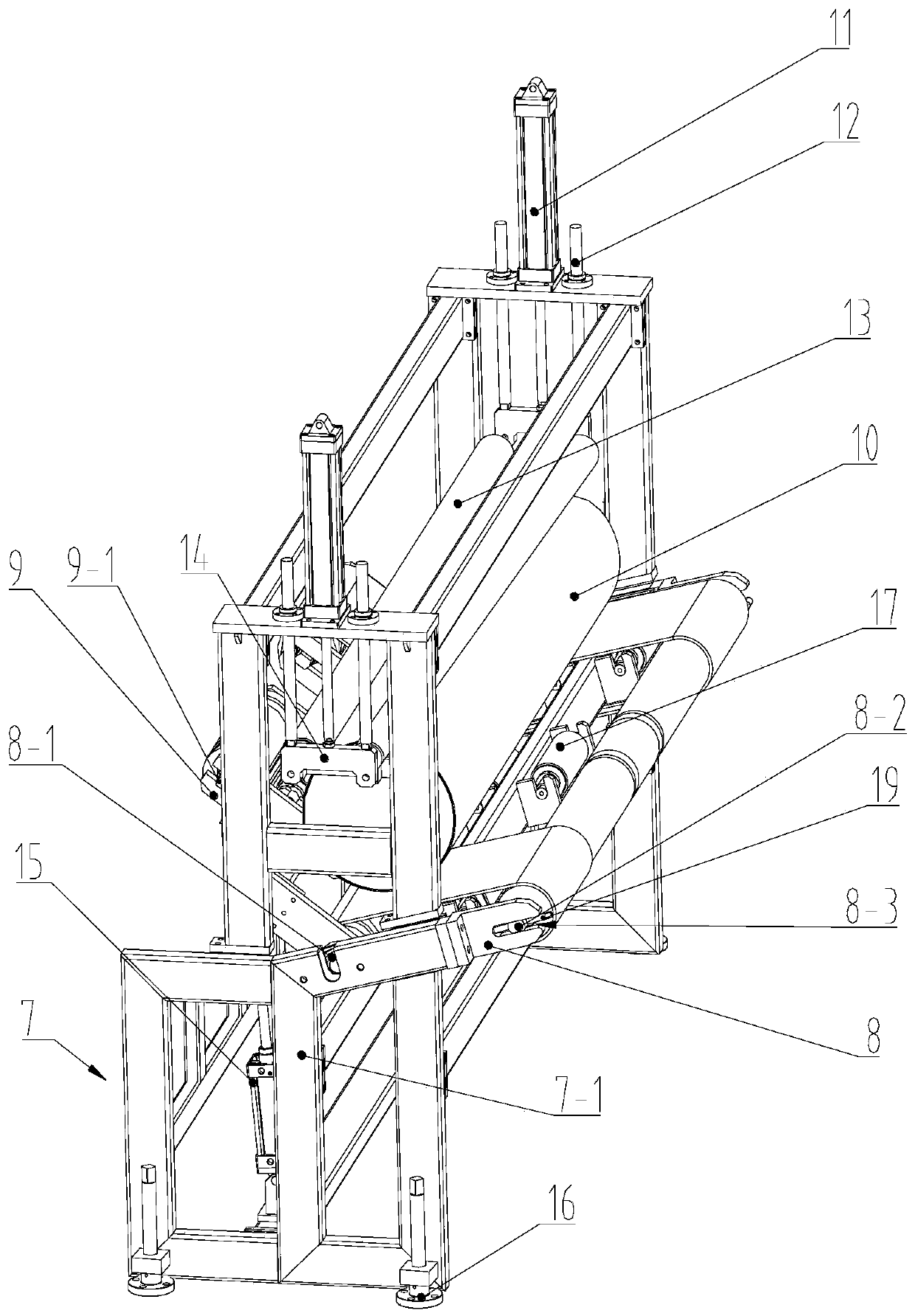

[0025] see Figure 1 to Figure 3, a friction winder for ultra-wide sheets, including a conveying device 1 and a winding device 2 . The conveying device 1 includes a chassis 3 , a motor 4 , and a belt transmission mechanism 5 . The belt transmission mechanism 5 is supported on the underframe 3, the driving roller 5-1 of the belt transmission mechanism 5 is connected with the motor 4 through the reduction mechanism 6, and the driven roller 5-2 of the belt transmission mechanism 5 is fixed by the mandrel 5-3 On the underframe 3, a conveyor belt is provided between the driving roller 5-1 and the driven roller 5-2. When the conveying device 1 is in operation, the motor 4 controls the rotation of the driving roller 5-1 through the reduction mechanism 6, and the driving roller 5 -1 drives the driven roller 5-2 to rotate through the conveyor belt between it and the driven roller 5-2, so that the conveying device 1 can continuously convey the sheet forward. The mandrel 5-3 is circumf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap