Electric melting crucible kiln for drawing flexible glass

A flexible glass and furnace technology, used in glass furnace equipment, electric furnaces, glass manufacturing equipment, etc., can solve the problems of uneven thickness of flexible glass, non-compliance with environmental protection requirements, poor quality of broken plates, etc. Efficient use of energy and effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

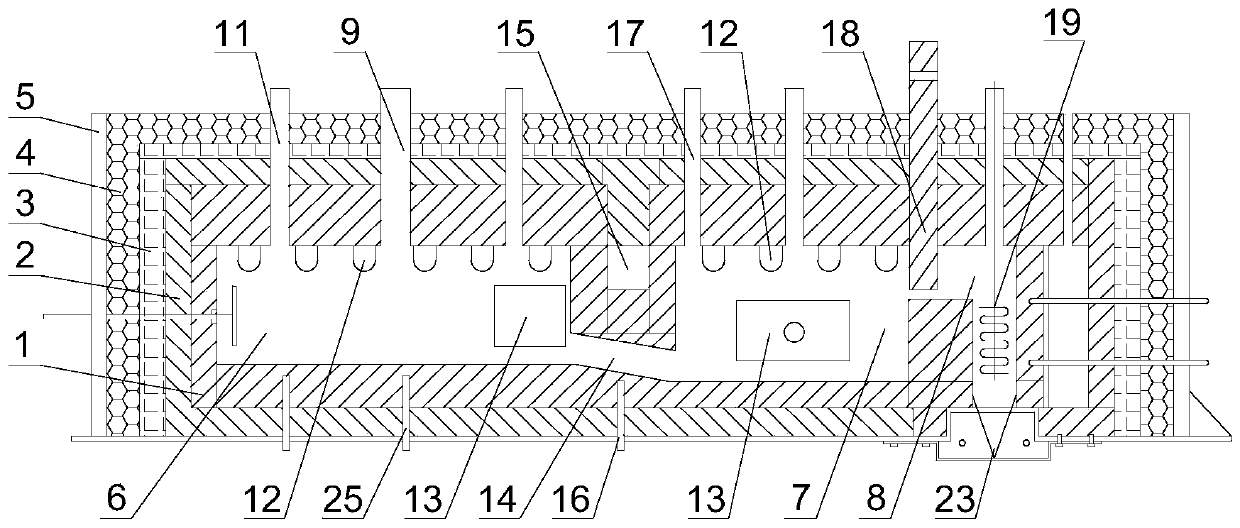

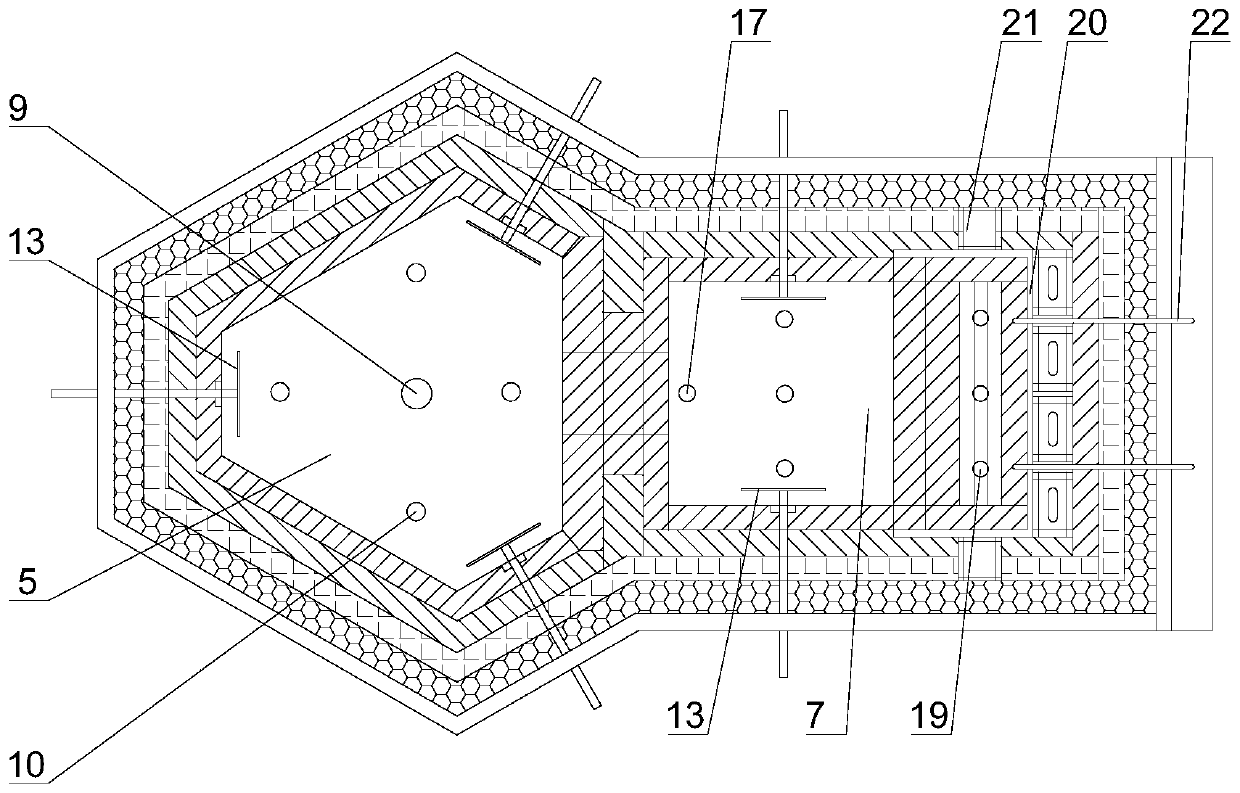

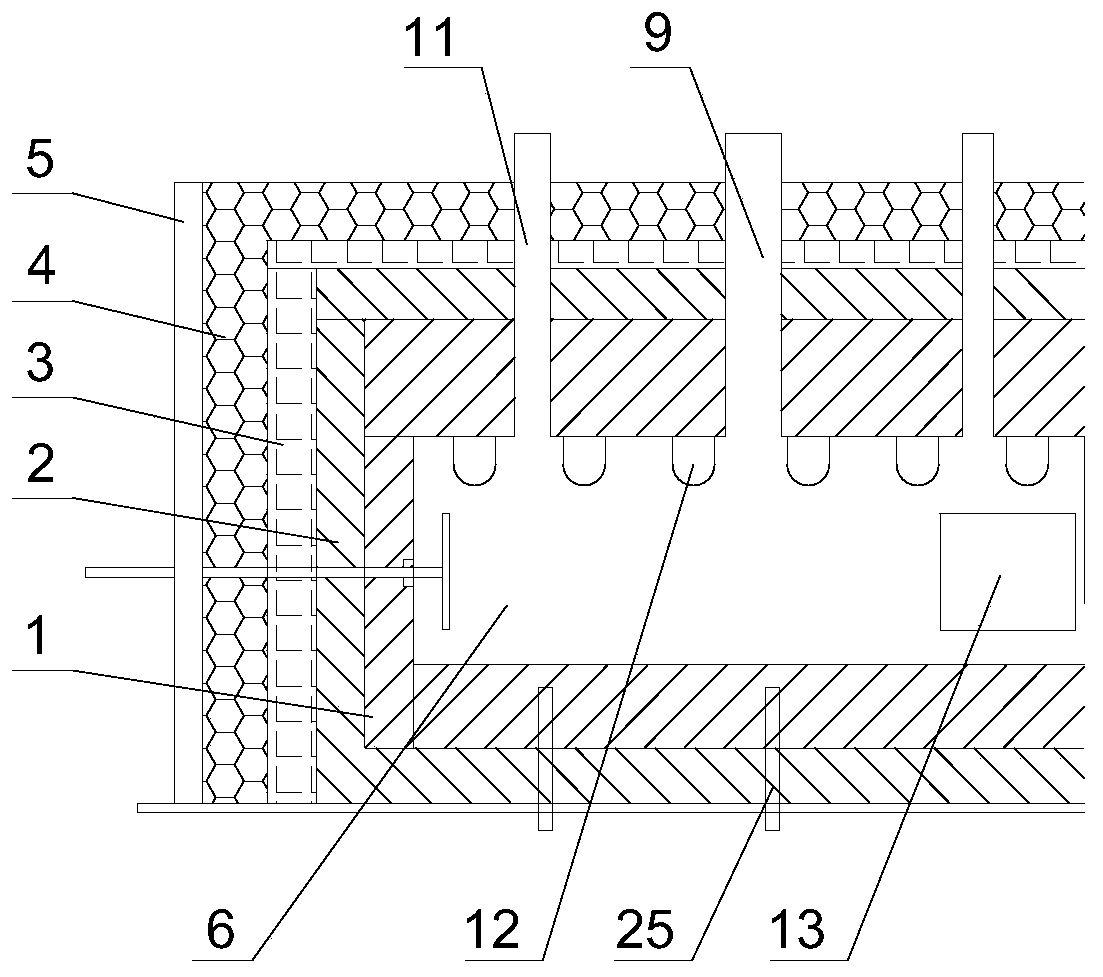

[0027] Specific examples, such as Figure 1 to Figure 7 As shown, an electric melting crucible kiln for drawing flexible glass includes a kiln body 1 surrounded by kiln bottom bricks, kiln side bricks and kiln cover bricks. The kiln body 1 includes The melting chamber 6, clarification chamber 7 and molding chamber 8 communicated in sequence from front to back, the upper end of the melting chamber 6 is provided with a feeding port, the lower end of the molding chamber 8 is provided with a discharge chute 23, and the The insides of the melting chamber 6, the clarification chamber 7 and the molding chamber 8 are all equipped with temperature detection devices and heating devices, and the feature is that: a flow channel 14 communicating between the melting chamber 6 and the clarification chamber 7 is provided; A cooling channel 15 is arranged above the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com