A method for simultaneously separating and purifying six flavonoids from sunflowers

A simultaneous separation technology of goldenflower and sunflower, which is applied in the field of natural compound extraction and separation, can solve the problems of complex operation, long production cycle, and limited application of flavonoids, and achieve the effect of high purity, short production cycle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

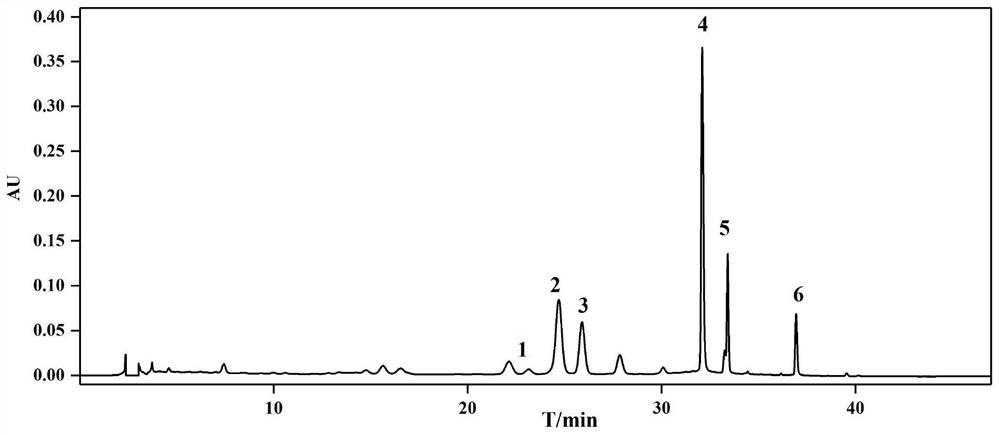

[0052] 1) Preparation of the extract of goldenflower sunflower: Precisely weigh 107g of dried goldenflower sunflower coarse powder, with a solid-liquid ratio of 1:20g / mL, 70% ethanol aqueous solution, 80°C as the extraction condition, microwave extraction for 10min, suction filtration, Repeat the extraction three times, collect the supernatant, and settle to a 250mL volumetric flask to obtain the goldenflower sunflower extract. Its high-performance liquid chromatogram is as follows: figure 1 shown;

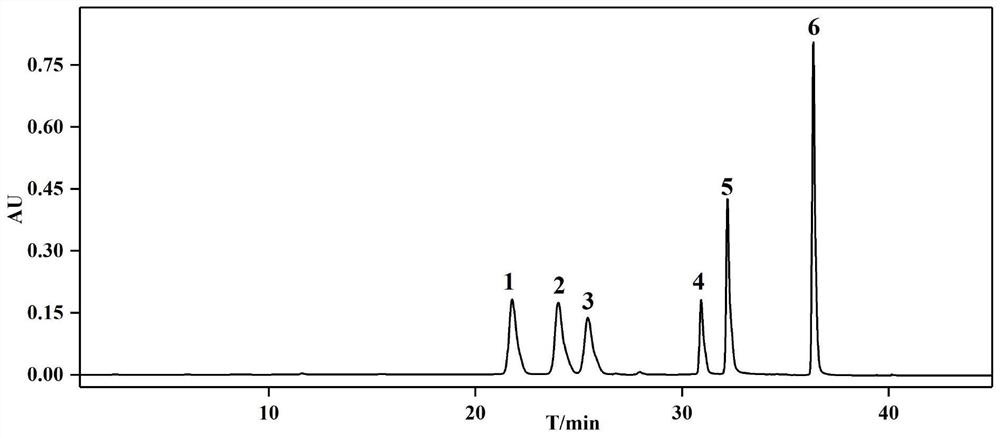

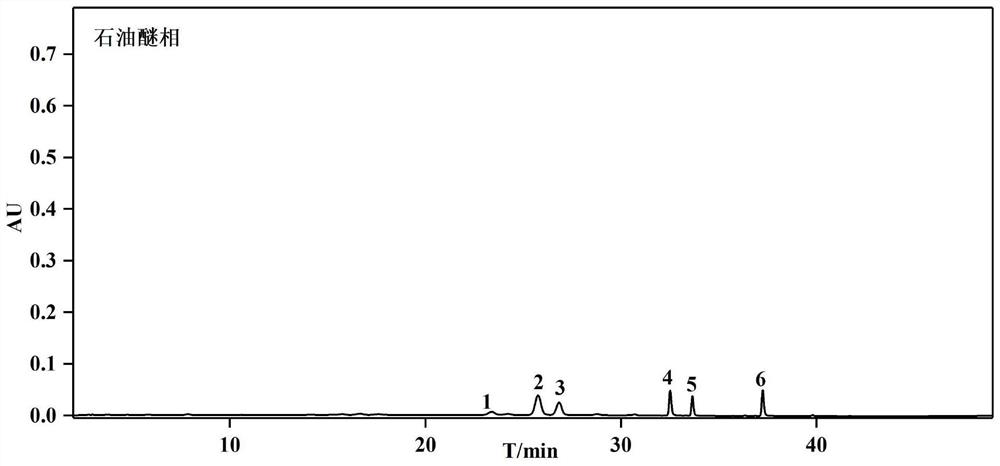

[0053] 2) Solvent extraction: extract the sunflower extract obtained in step 1) with an equivalent amount of petroleum ether, ethyl acetate and n-butanol, repeat the extraction 3 times, combine the extracts, concentrate under reduced pressure, and set the volume to 250mL Volumetric flask, obtain Jinhua sunflower petroleum ether phase, ethyl acetate phase, n-butanol phase and water phase, the HPLC of its petroleum ether phase, ethyl acetate phase, n-butanol phase and water phase ar...

Embodiment 2

[0067] The basic operation is the same as in Example 1, the difference is that 110g of dried goldenrod sunflower coarse powder is accurately weighed, and after HPLC analysis, 35.4mg of rutin is obtained with a purity of 96.87%; 72.5mg of hyperoside is obtained with a purity of 95.37%; 67.5mg of isoquercitrin was obtained with a purity of 98.34%; 151.8mg of cottonsein-8-O-glucuronide was obtained with a purity of 99.27%; 63.2mg of myricetin was obtained with a purity of 96.58%; Cortex 25.3mg, purity 95.78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com