Ultramicro black fungus powder purification system based on negative pressure

A black fungus powder, ultra-fine technology, applied in the directions of magnetic separation, solid separation, and separation of solids from solids with airflow, etc., can solve the problem of affecting the use effect of black fungus powder, low degree of refinement, and efficiency of iron removal equipment low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

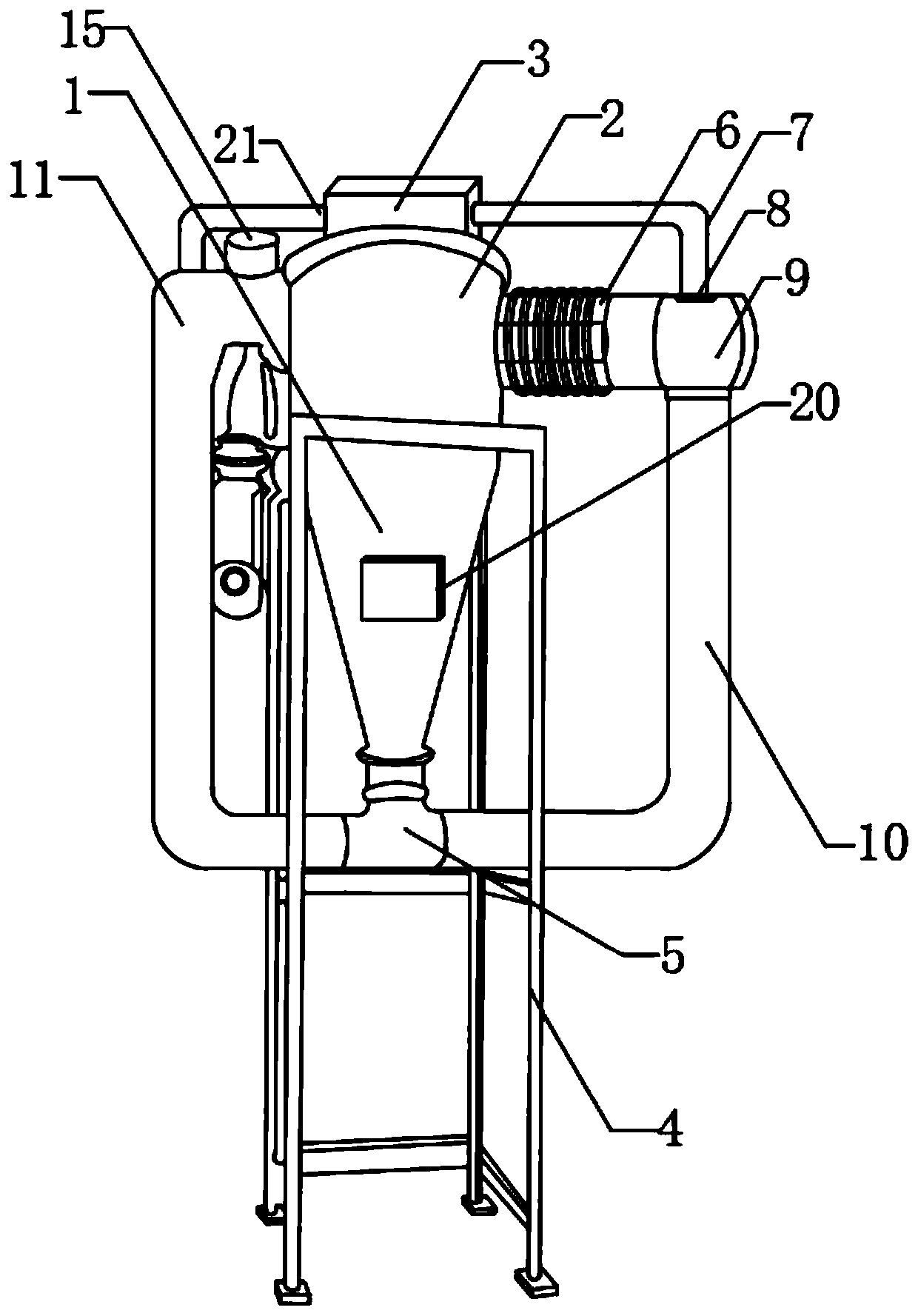

[0025] Such as Figure 1-5 As shown, a negative pressure-based ultrafine black fungus powder purification system includes a purification tank (1) and a hollow cylinder (6). The top of the purification tank (1) is fixedly equipped with a feeding chamber (2), and the hollow circle The cylinder (6) is fixedly mounted on one side of the feeding cavity (2), the surface of the purification tank (1) is provided with a control panel (20), and the purification tank (1) is fixedly mounted on the top of the bracket (4).

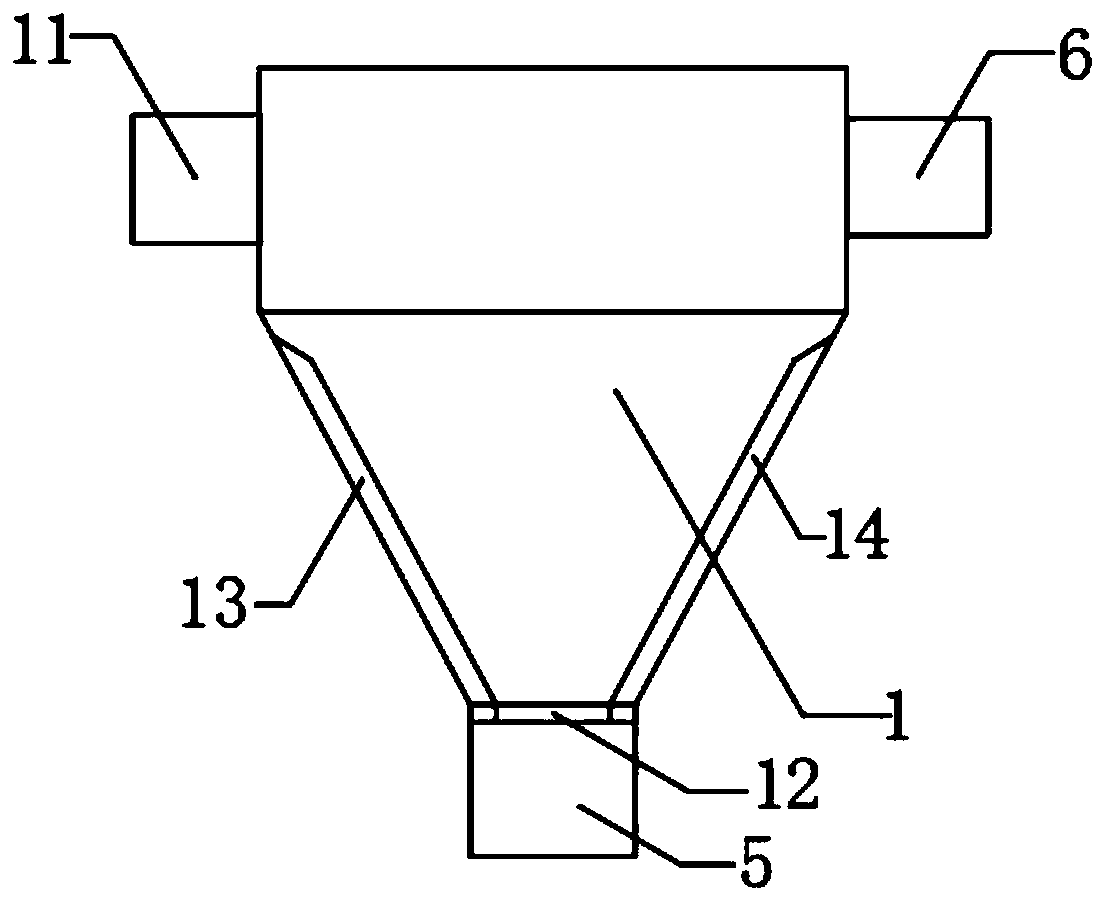

[0026] The purification tank (1) is trapezoidal, and a magnetic slide plate (13) is installed on the surface of one side of the inner wall of the purification tank (1), and an ordinary slide plate (14) is installed on the other side surface of the inner wall of the purification tank (1). A circular magnetic plate (12) is installed at the bottom of the circular magnetic plate (12), and several circular holes (19) are provided on the surface of the circular magnetic plate...

Embodiment 2

[0034] Such as Figure 1-5 As shown, a negative pressure-based ultrafine black fungus powder purification system, such as Figure 1-5 As shown, a negative pressure-based ultrafine black fungus powder purification system includes a purification tank (1) and a hollow cylinder (6). The top of the purification tank (1) is fixedly equipped with a feeding chamber (2), and the hollow circle The cylinder (6) is fixedly mounted on one side of the feeding cavity (2), the surface of the purification tank (1) is provided with a control panel (20), and the purification tank (1) is fixedly mounted on the top of the bracket (4).

[0035] The surface of the hollow cylinder (6) is wound with a coil (16), and the hollow cylinder (6) is made of a transparent material. The top of bar (17) is equipped with solid iron core (18), and one side of hollow cylinder (6) cross section is equipped with separating cavity (9), and the surface spraying of solid iron core (18) is provided with white lacquer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com