A new method and application of producing ferulic acid esterase by fermenting straw of Pyrocystis sp.

The technology of ferulic acid esterase and Trichoderma piriformis is applied in the field of anaerobic fermentation of Leymus chinensis to produce ferulic acid esterase, which can solve the problems of low conversion efficiency, long pretreatment time and high cost, and achieves improved economic benefits, Simple fermentation process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the preparation of piromyces Piromyces CY1 inoculum:

[0034]Draw 1mL of Piromyces CY1 culture and inoculate it into a 20mL Heinz anaerobic tube with 9mL of liquid basic medium based on 0.1g of air-dried and crushed wheat straw. The final concentrations of chloramphenicol in the liquid basic medium were 1600IU / mL and 2000IU / mL respectively, and the final concentration of chloramphenicol in the medium was 50 μg / mL. After anaerobic culture at 39°C for 72 hours, the growth peak is reached, and the fermentation broth is a high-activity bacterial agent at this time.

Embodiment 2

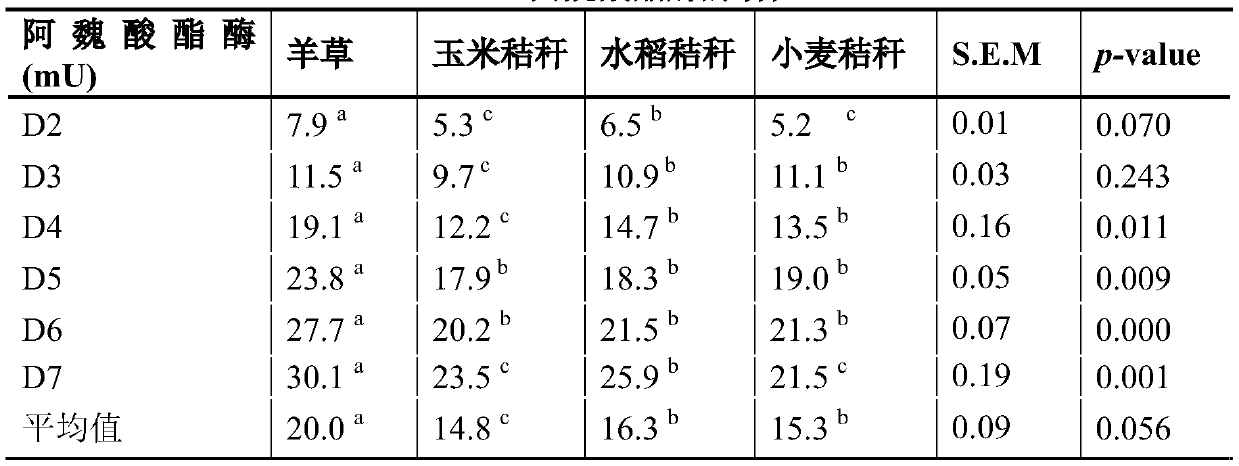

[0035] Example 2: Production of ferulic acid esterase by anaerobic fermentation of Leymus chinensis by Piromyces CY1

[0036] 1. The method for producing ferulic acid esterase by anaerobic fermentation Leymus chinensis

[0037] 90mL of liquid basic medium was placed in a 100mL anaerobic fermentation bottle, and 1.0g of crushed and air-dried Leymus chinensis, rice straw, wheat straw and corn straw were used as substrates. Deoxygenation. Sterilize. Inoculate 10 mL of Piromyces CY1 subcultured for 72 hours into the above-mentioned anaerobic medium with Leymus chinensis, rice straw, wheat straw and corn straw as substrates, and compound antibiotics were added at the same time to make it The final concentration of penicillin 1600IU / mL and streptomycin sulfate 2000IU / mL in the anaerobic medium solution, the final concentration of chloramphenicol in the medium was 50 μg / mL, and anaerobic culture was carried out at 39°C for 7 days. A total of 3 parallel experiments were set up to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com