Steel box girder installation system and construction method thereof

A technology for installation system and steel box girder, which is applied to bridges, bridge materials, bridge construction, etc., can solve the problems of reduced service life of steel box girders, consumption of manpower and material resources, and increased construction difficulty, so as to shorten the construction period and improve construction efficiency. Efficiency, guaranteed normal operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

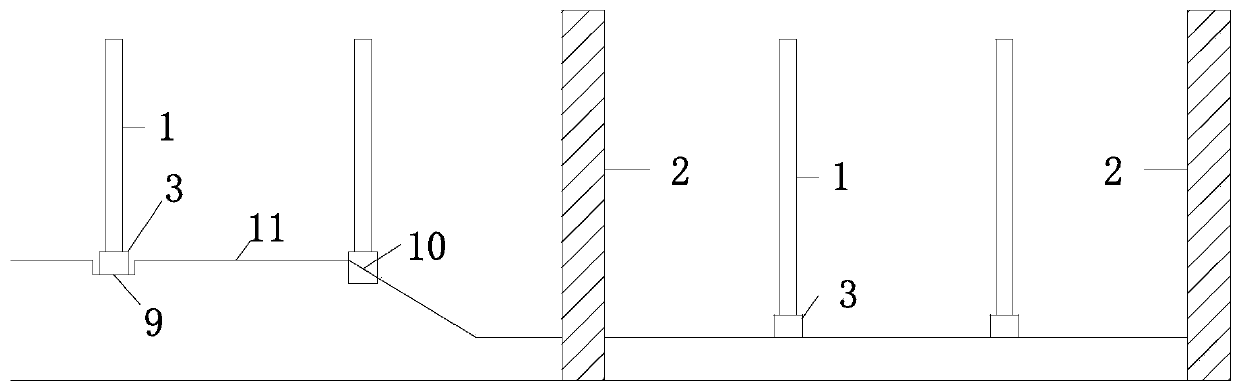

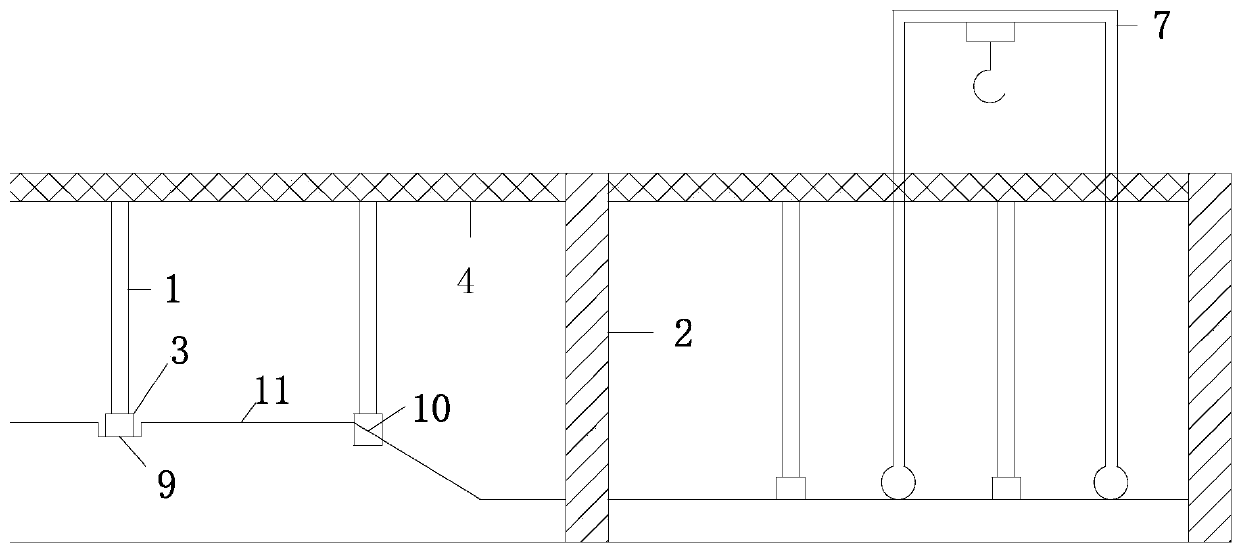

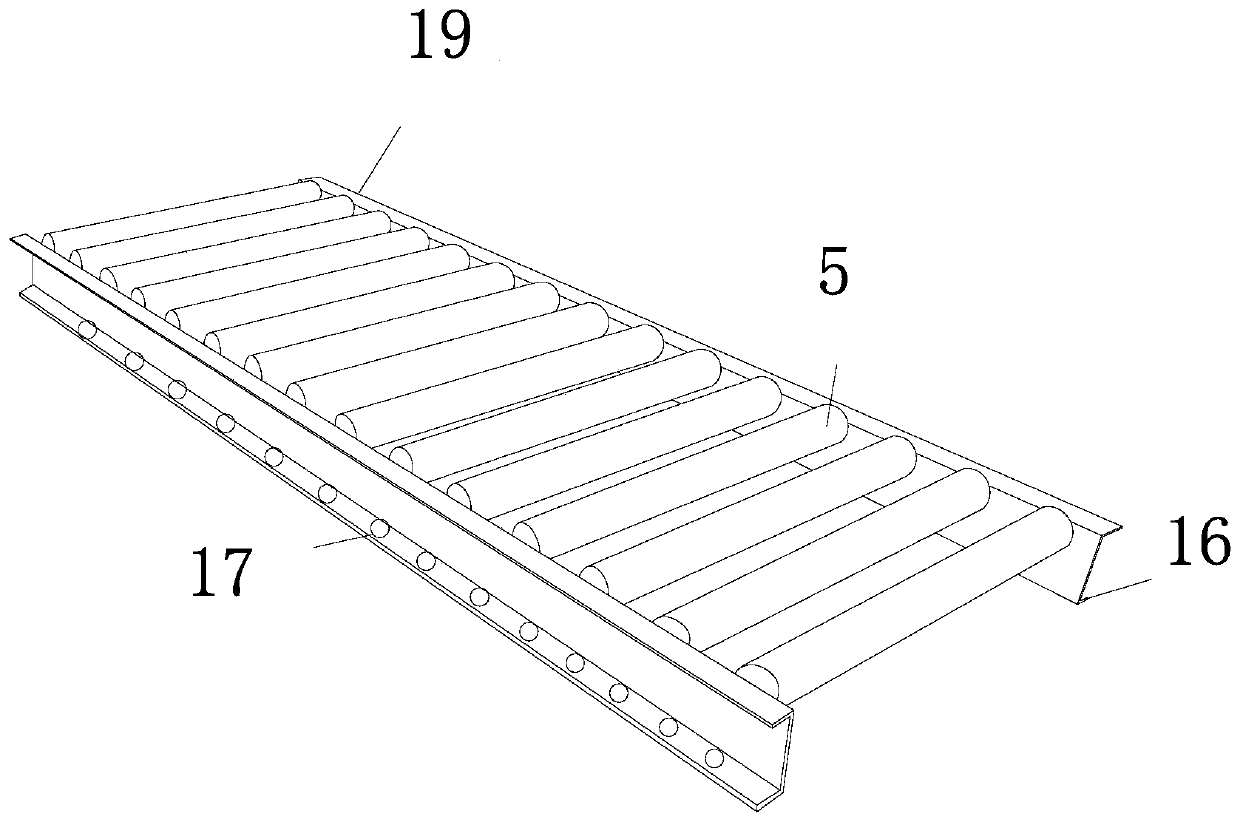

[0046] In the steel box girder installation system, support foundations 3 are set on the central isolation belt 9, road shoulders 10, and both sides of the crossed road, temporary supports 1 are set on the support foundations 3 between buttresses 2, and temporary supports 1 are installed. The Bailey beam 4 connected with the roller system 19, the roller system 19 is composed of the roller 5 and the channel steel 16 with the screw hole 17 on the lower wing plate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com