Novel spraying-direction gradual-change type mortar throwing-ejection device

A gradient, mortar technology, applied in the direction of architecture, building structure, etc., can solve the problems of high energy consumption, large structure, complex structure, etc., and achieve the effect of uniform spraying of mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

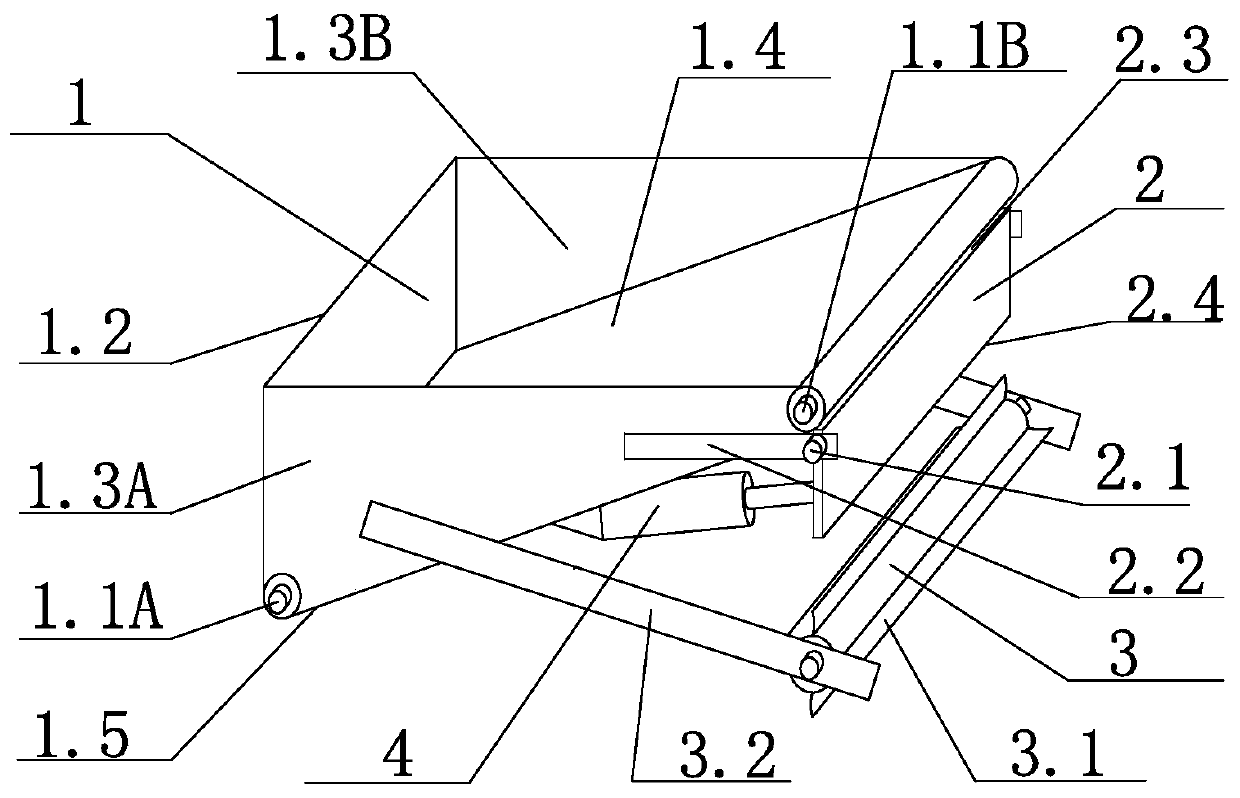

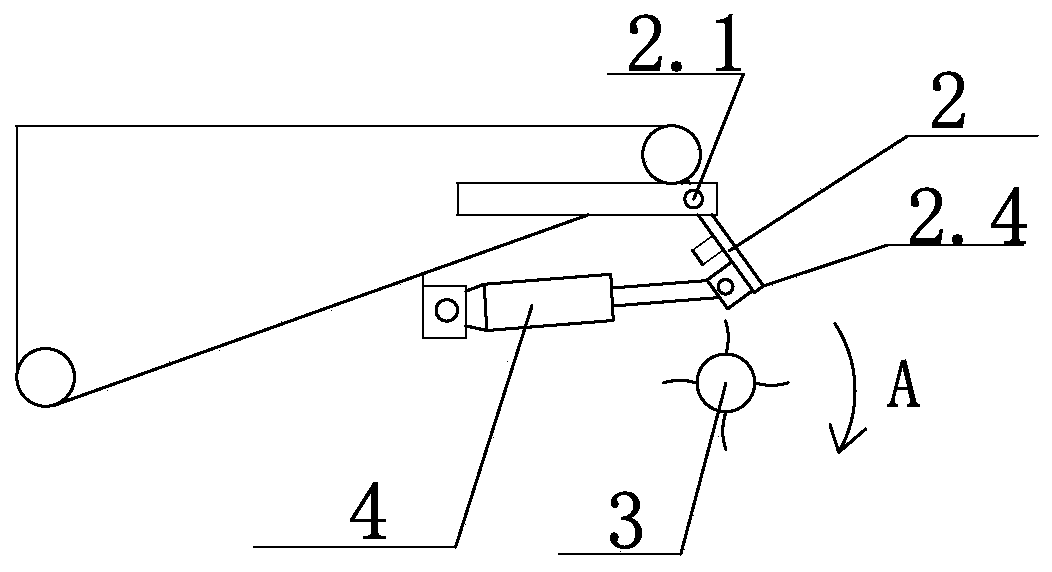

[0047] Such as Figure 1-Figure 4 As shown, the new spraying direction gradual change type mortar ejection device of the present invention comprises a hopper, the bottom of the hopper is provided with a conveyor belt 1.4 which is inclined to transport upwards, a material guide plate 2 is provided below the outlet end of the conveyor belt 1.4, and two tops of the material guide plate 2 are provided. The material guide plate support 2.2 is hinged on the side, the material guide plate support 2.2 is connected to the hopper, the bottom end of the material guide plate 2 is connected to the hopper through a movable joint, and a mortar throwing roller 3 is arranged below the material guide plate 2 . The hopper includes the hopper body 1, the side elevation A1.3A, the side elevation B1.3B, and the end elevation 1.2 constitute the three elevations of the hopper body 1. The inclined bottom surface of the hopper is a conveyor belt, and a bottom shell 1.5 is arranged below the conveyor bel...

Embodiment 2

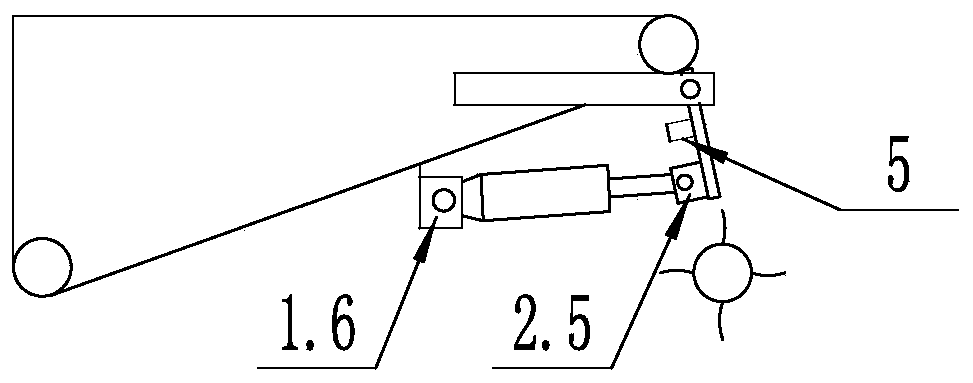

[0064] The movable range of the material guide plate 2 is located, and the material guide plate 2 is vertically arranged downwards, corresponding to the inner side of the cylinder horizontal diameter of the mortar throwing roller 3; and corresponding to the horizontal diameter of the mortar throwing roller 3 in the vertical direction with the bottom end of the material guide plate 2 between the outer ends. Such as figure 2 As shown, the material guide plate is at the far right; Figure 4 As shown, the material guide plate is at the leftmost state; when the electric push rod pushes the material guide plate to move, it moves between the leftmost end and the rightmost end. All the other are with embodiment 1.

Embodiment 3

[0066] Such as Figure 5-Figure 6 As shown, the edge 2.3 on the material guide plate is in the shape of a knife edge. Such as Figure 6 As shown, the material guide plate is in the shape of a knife on one side. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com