Inflatable shield tail sealing device

A shield tail sealing and inflatable technology, used in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of harsh working environment, difficult replacement, large wear and tear, and achieve the effect of preventing mud from infiltrating into the shield tail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

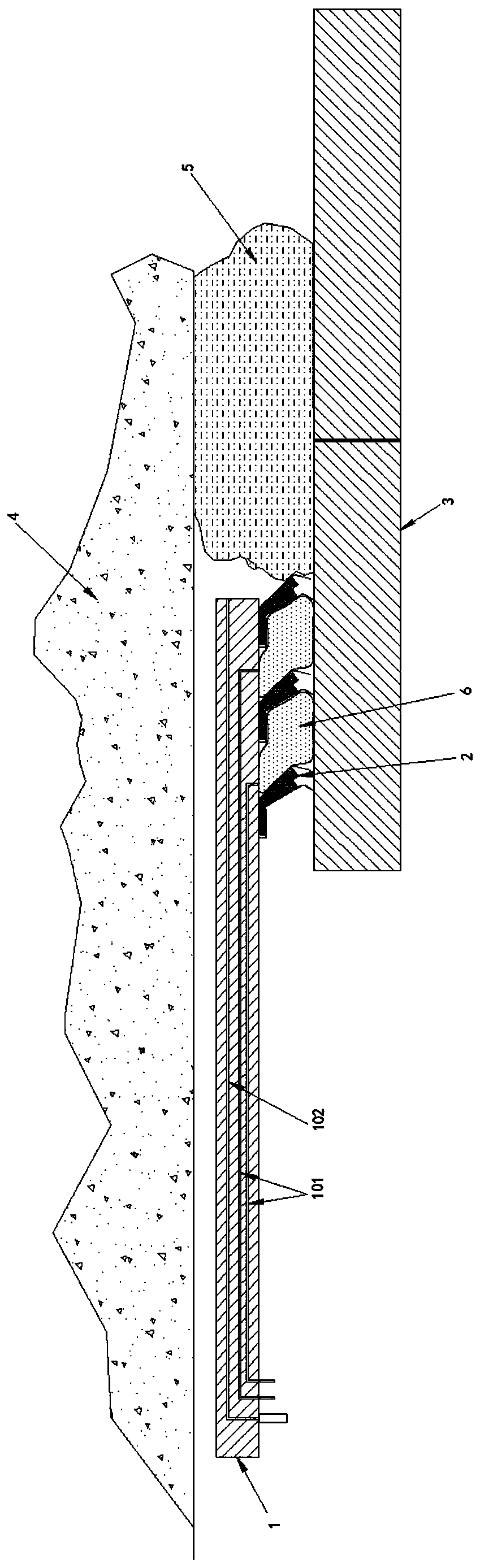

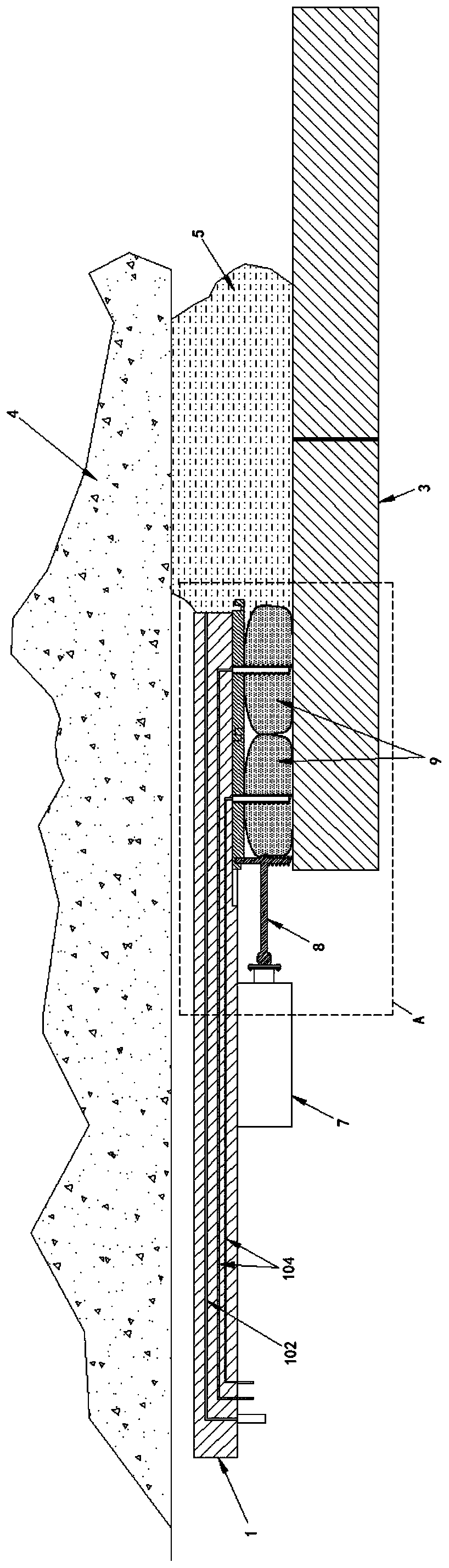

[0027] Such as figure 2 and image 3 As shown, the inflatable shield tail sealing device of this embodiment includes a shield tail 1, a linear drive 7, a connecting rod 8 and two airbags 9;

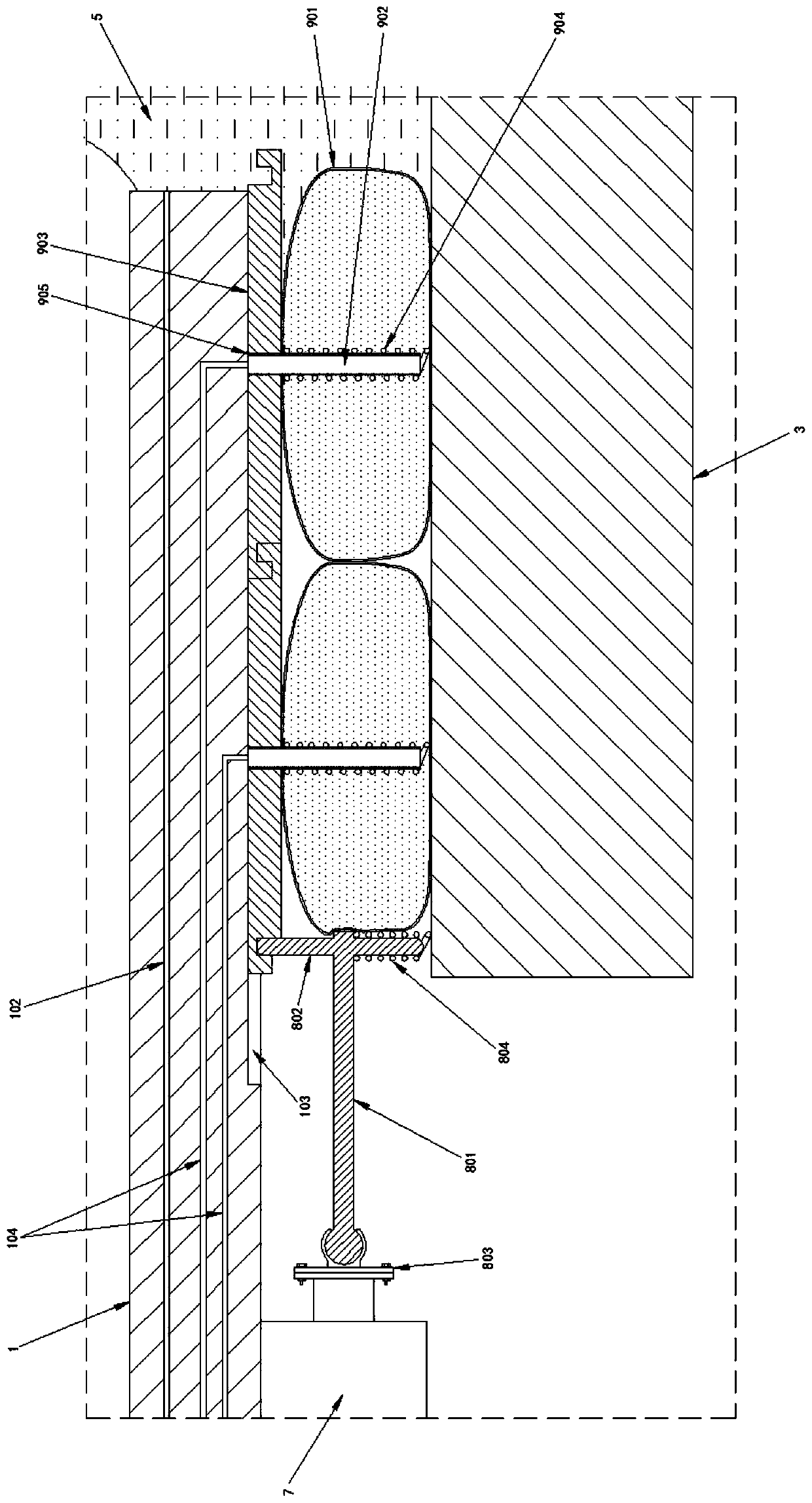

[0028] Such as image 3 and Figure 4 As shown, the airbag 9 includes an airbag body 901, an air nozzle 902 and a connector 903. The airbag body 901 is in a circular shape, and one end of the air nozzle 902 is inserted into the airbag body 901 and the other end is inserted into the connector 903. The air nozzle 902 is located at the airbag body. One end in 901 is covered with a first spring 904; the surface of the connecting piece 903 is provided with an annular groove, and a rubber gasket 905 is installed in the annular groove, and both ends of the connecting piece 903 are provided with tenons and tenon grooves that can engage with each other; The nozzles 902 are evenly distributed around the central axis of the airbag body 901; each air nozzle 902 is equipped with a connecting piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com