Micro channel condenser for circulating type air source heat pump water heater

An air-source heat pump and micro-channel technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of low heat exchange efficiency and limited use occasions, and achieve increased heat exchange coefficient and reduced weight. , The effect of easy recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

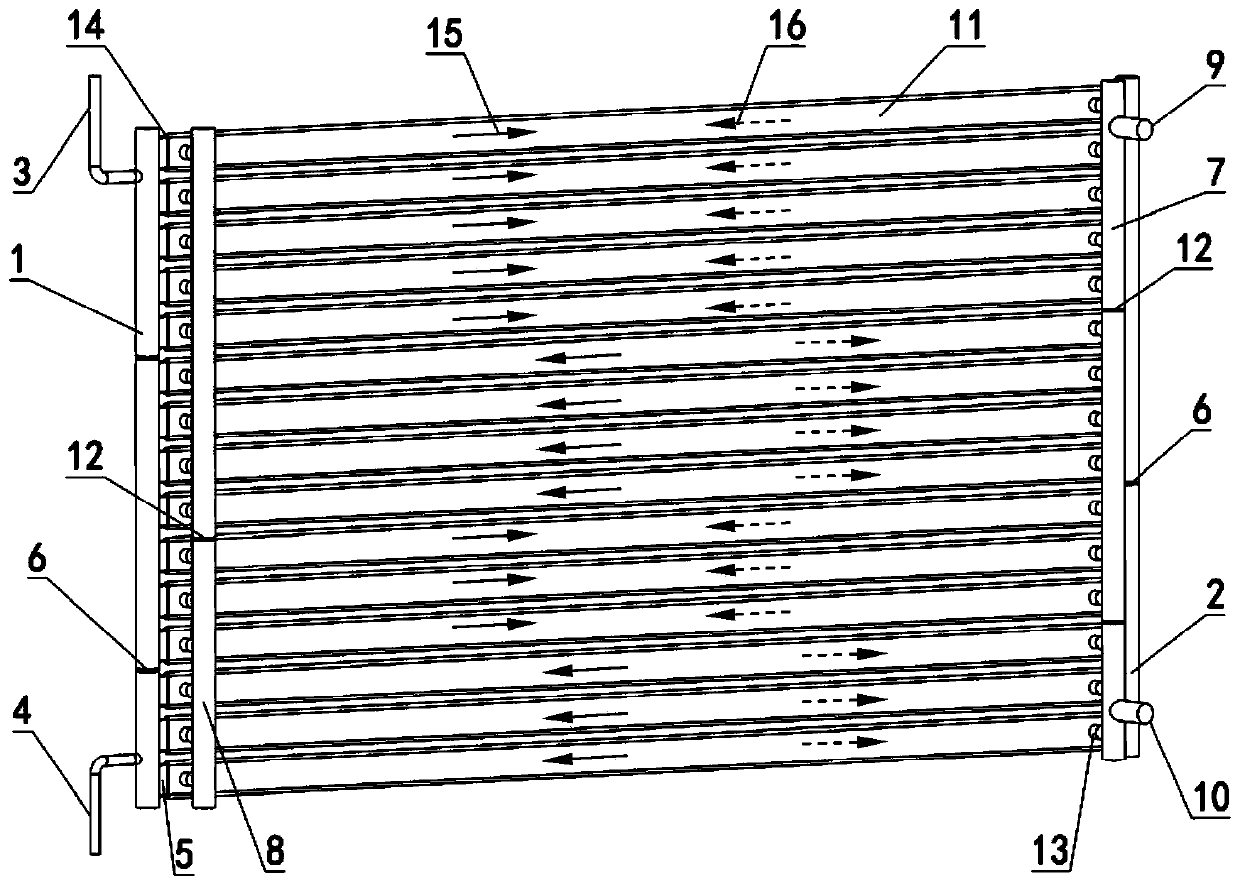

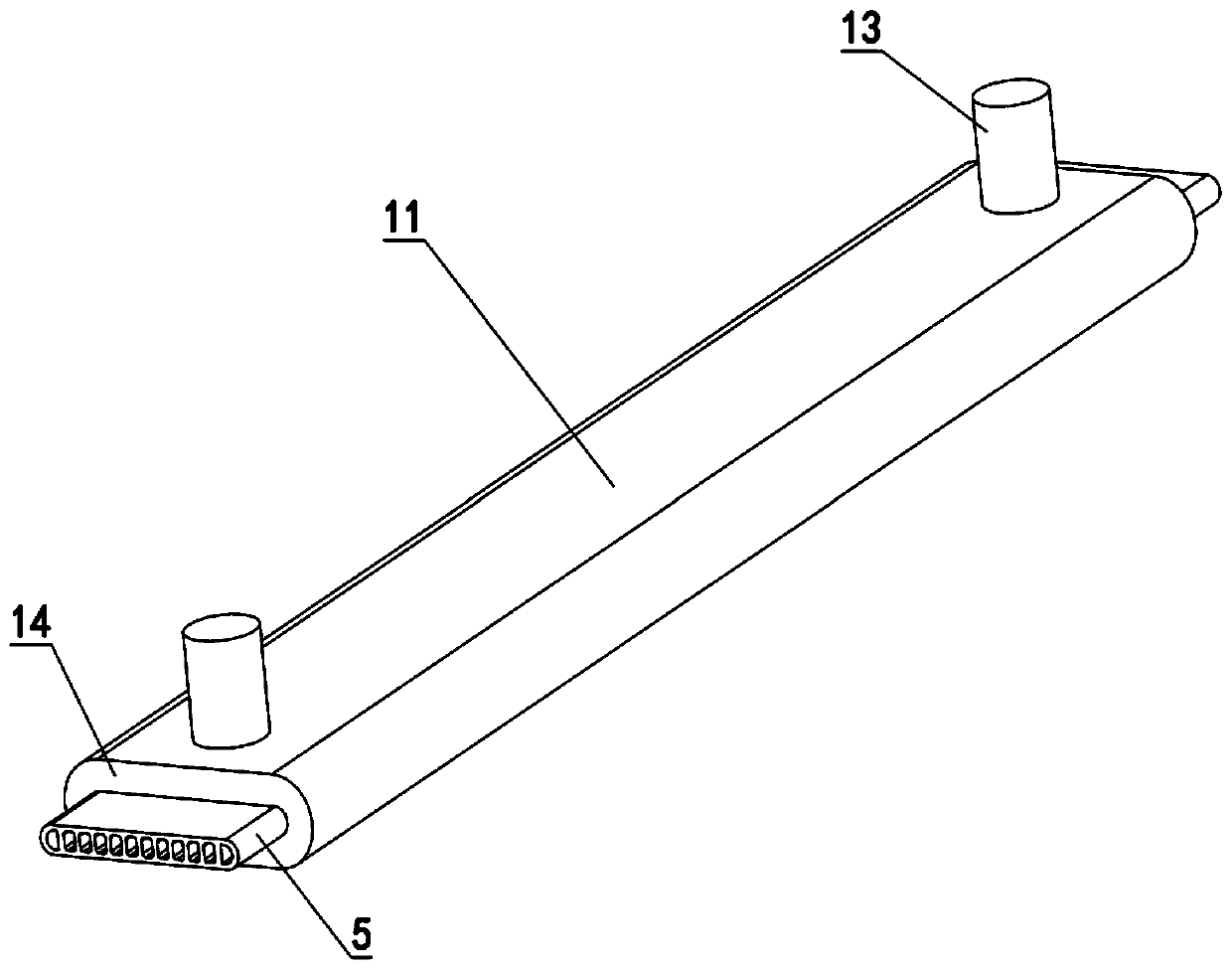

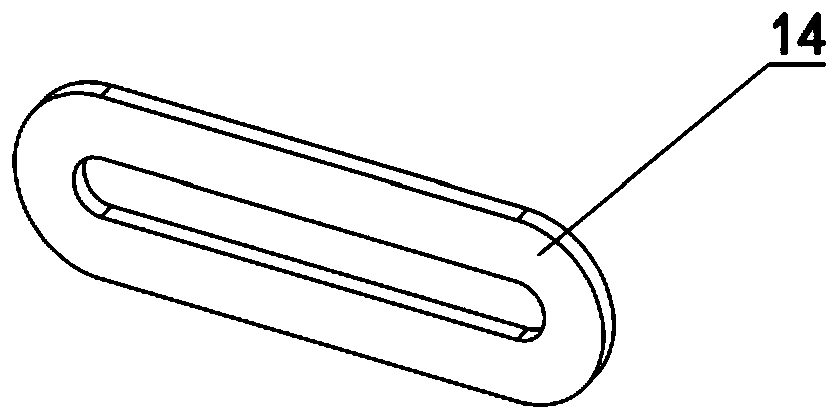

[0025] Such as Figure 1 to Figure 3 As shown, figure 1 It is a schematic diagram of the overall three-dimensional structure of a micro-channel condenser used in a circulating air source heat pump water heater in this embodiment, including a first refrigerant header 1, a second refrigerant header 2, and a refrigerant intake pipe 3. Refrigerant outlet pipe 4. Refrigerant microchannel flat pipe 5, Refrigerant partition plate 6; Water first header 7, water second header 8, cold water inlet pipe 9, hot water outlet pipe 10, Water flat tube 11, water partition 12, water flow tube 13, and end cover 14. For the refrigerant side flow channel: the first refrigerant header 1 and the second refrigerant header 2 are connected to both ends of each refrigerant microchannel flat tube 5, and the first header 7 and The second water header 8 is in communication with a number of water flow tubes 13, and each water flow tube 13 is connected to a corresponding water flat tube 11; the refrigerant i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com