Heat storage material filling method capable of improving sensible heat storage density of solid and heat storage device

A technology of solid heat storage and heat storage material, which is applied in the directions of heat storage equipment, heat exchanger types, indirect heat exchangers, etc. Solid sensible heat heat storage density and other issues, to achieve the effect of increasing solid sensible heat heat storage density, conducive to widespread promotion and use, and improving heat storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

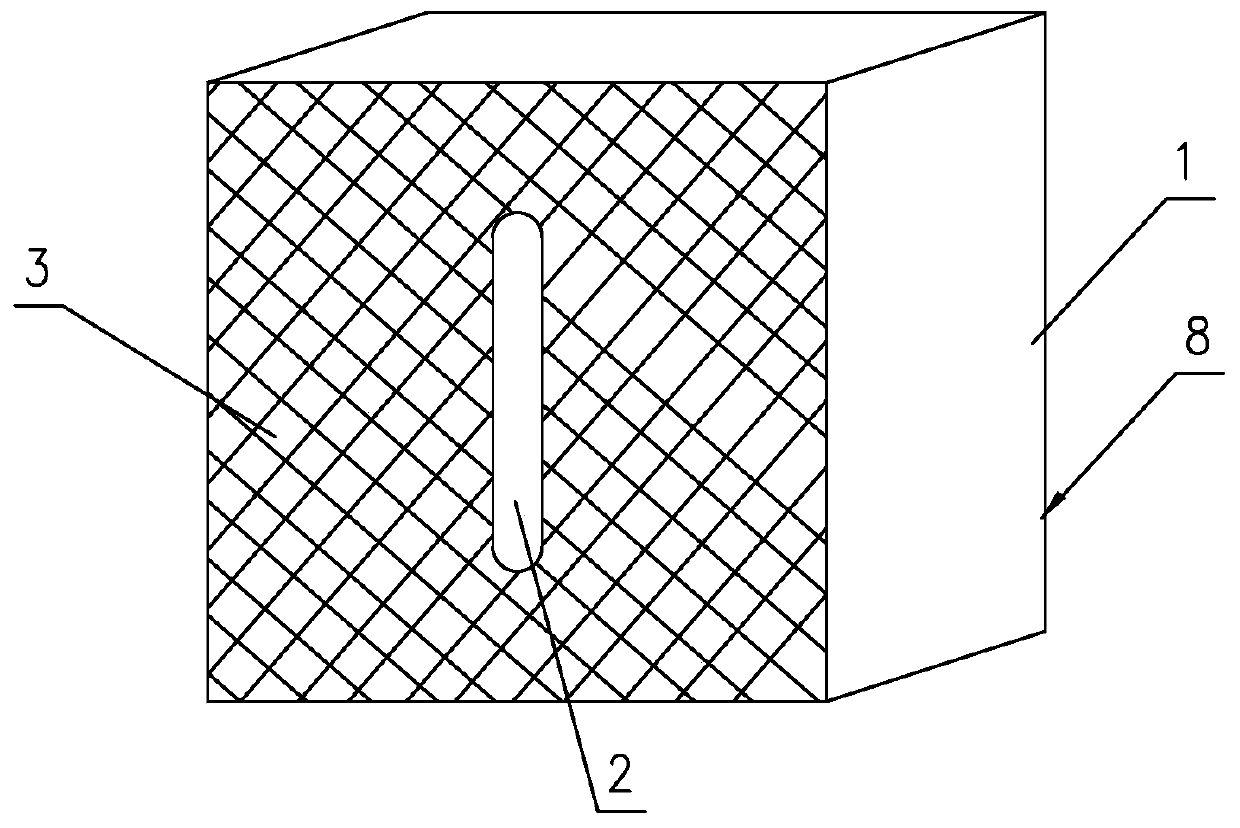

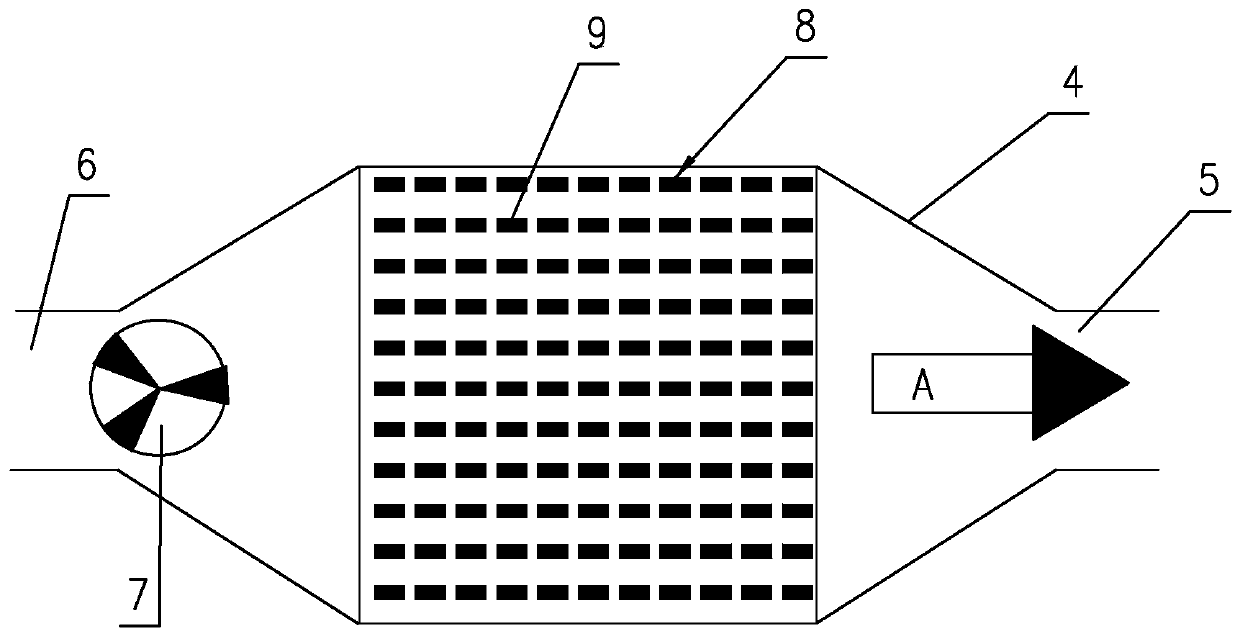

[0032] Such as figure 1 Shown is a heat storage device 8 of the present invention, which includes a housing 1, a solid heat storage material filled in the housing 1 and a heater (not shown in the figure), the housing 1 is a cube, and the solid storage An air duct 2 is arranged in the thermal material, and the air duct 2 is a straight air duct. The air duct 2 runs through the housing 1 and forms an air inlet and an air outlet on the opposite side walls of the housing 1. The housing where the air inlet and the air outlet are located The wall surface of the body 1 is a mesh surface 3, and the mesh aperture of the mesh surface 3 is 2 cm. In this embodiment, the heater is fixed on the inner wall surface of the housing 1, that is, the inner wall surface can be the top surface, left and right sides of the housing 1, the heater is located at the periphery of the air duct 2 and is in the solid heat storage material and engage with it.

[0033] The solid heat storage material is fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com