Three-dimensional reconstruction system calibration method based on multi-frequency structured light

A 3D reconstruction and system calibration technology, applied in the field of optical inspection, can solve problems such as low efficiency and cumbersome calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

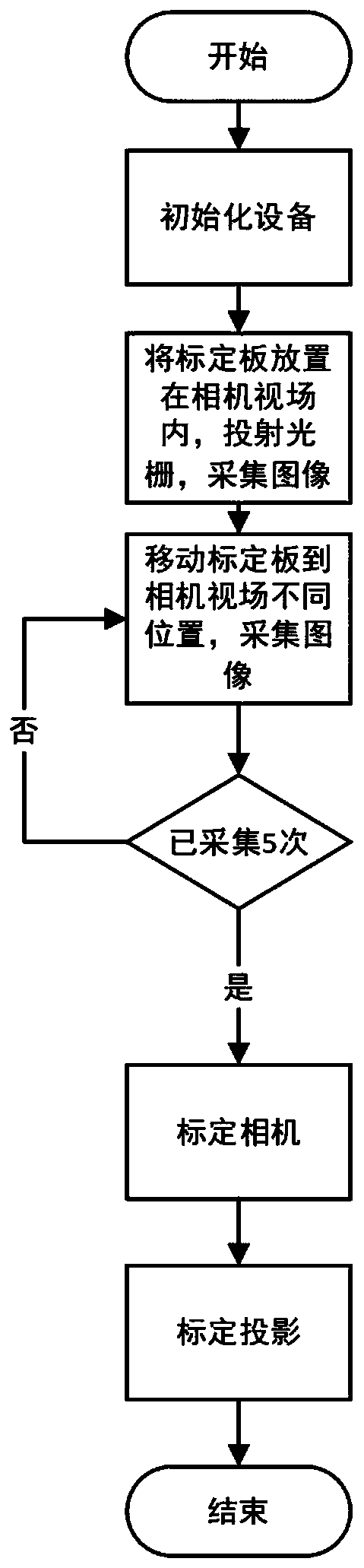

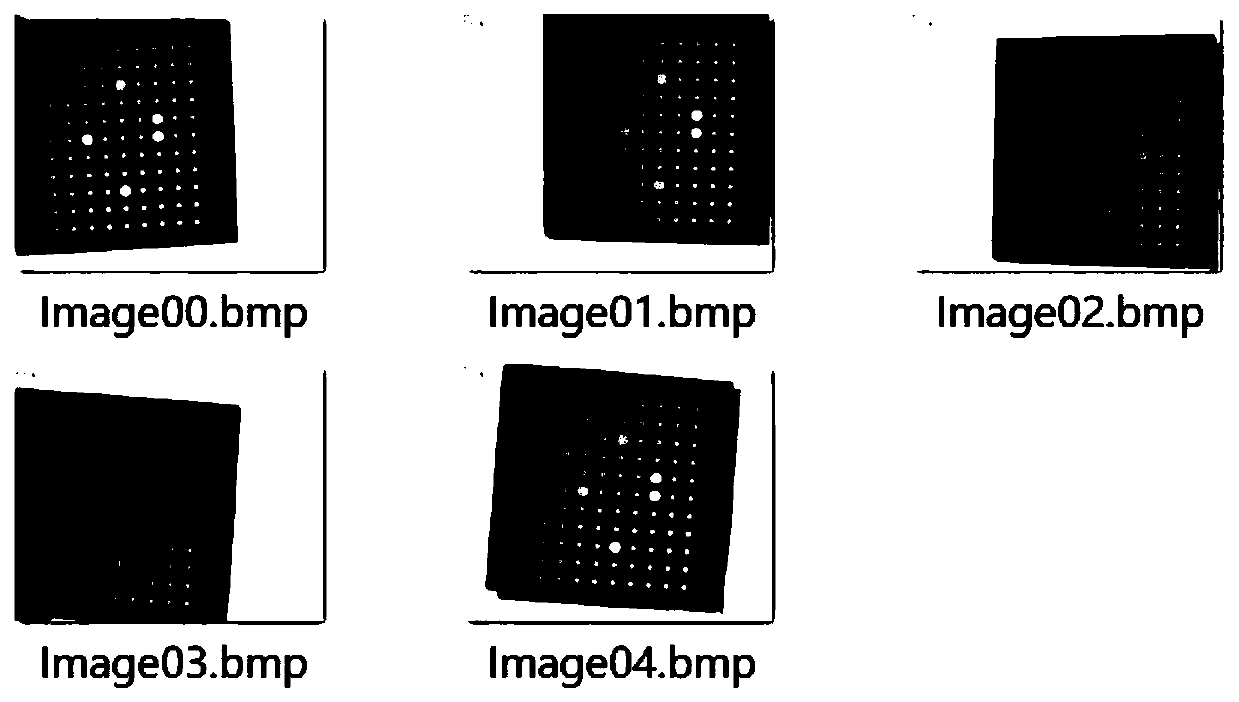

[0091] Such as Figure 1 to Figure 7 As shown, this embodiment discloses a calibration method for a 3D reconstruction system based on multi-frequency structured light. The 3D reconstruction system includes a loading platform, a fastening bracket that can move up and down, and rotate left and right, and an X-axis The slide rail, the Y-axis slide rail on the bracket, the grating projector installed on the Y-axis slide rail, the camera installed on the X-axis slide rail, and the acquisition device connected with the camera, the calibration method specifically includes the following steps :

[0092] Step S1: Initialize the device: adjust the height of the fastening bracket to change the object distance of the camera; adjust the focal length of the camera lens to make the object under test image clearly; adjust the position, angle and focal length of the projector to make it appear clear, Complete like.

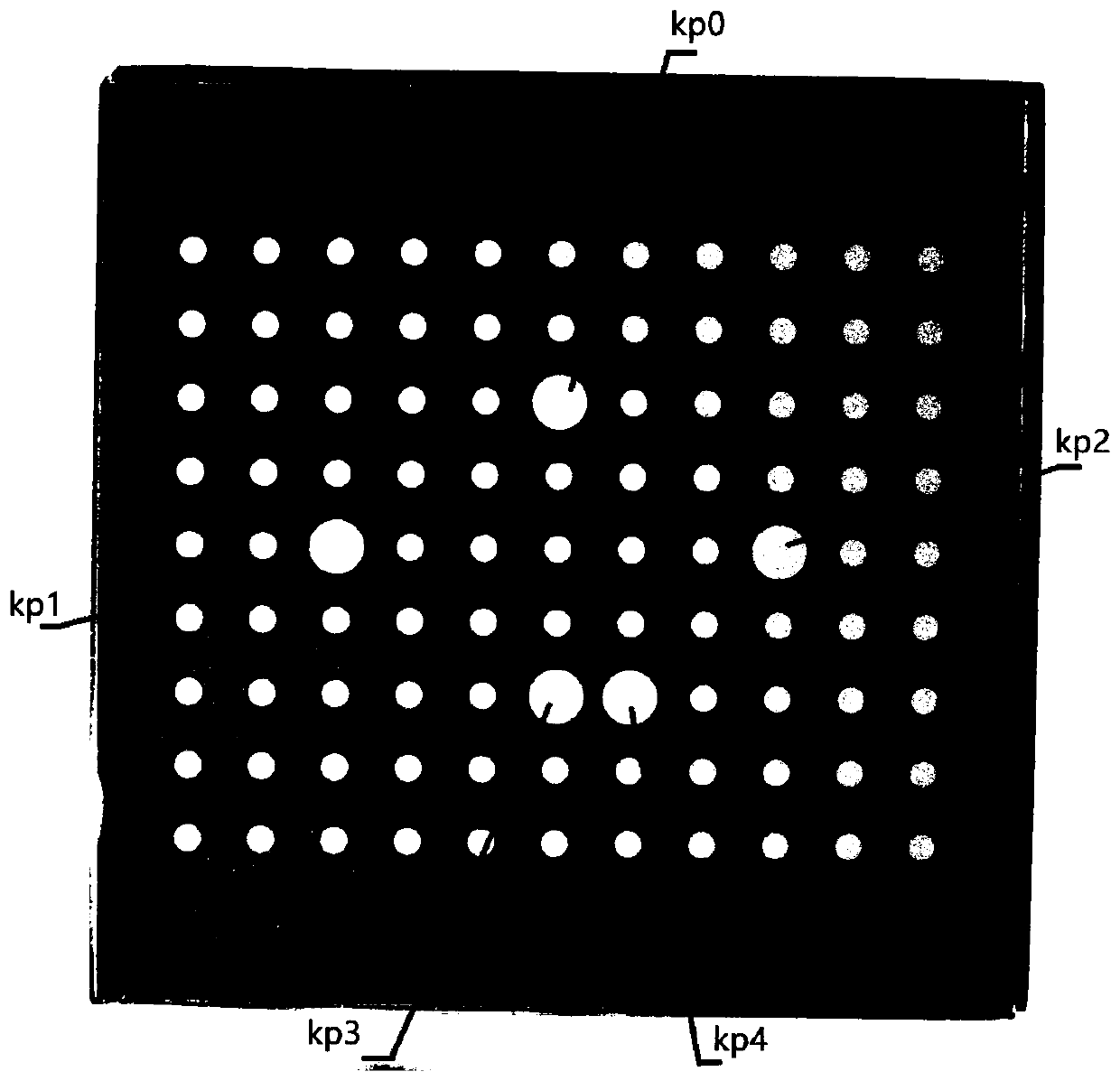

[0093] Step S2: Prepare the calibration board: This system uses a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com