Floating adjustable temperature controller with over-temperature protection contact

A floating type, thermostat technology, applied in the direction of heating/cooling contact switch, thermal switch parts, etc., can solve the problems of many processes, large space occupation, and many parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

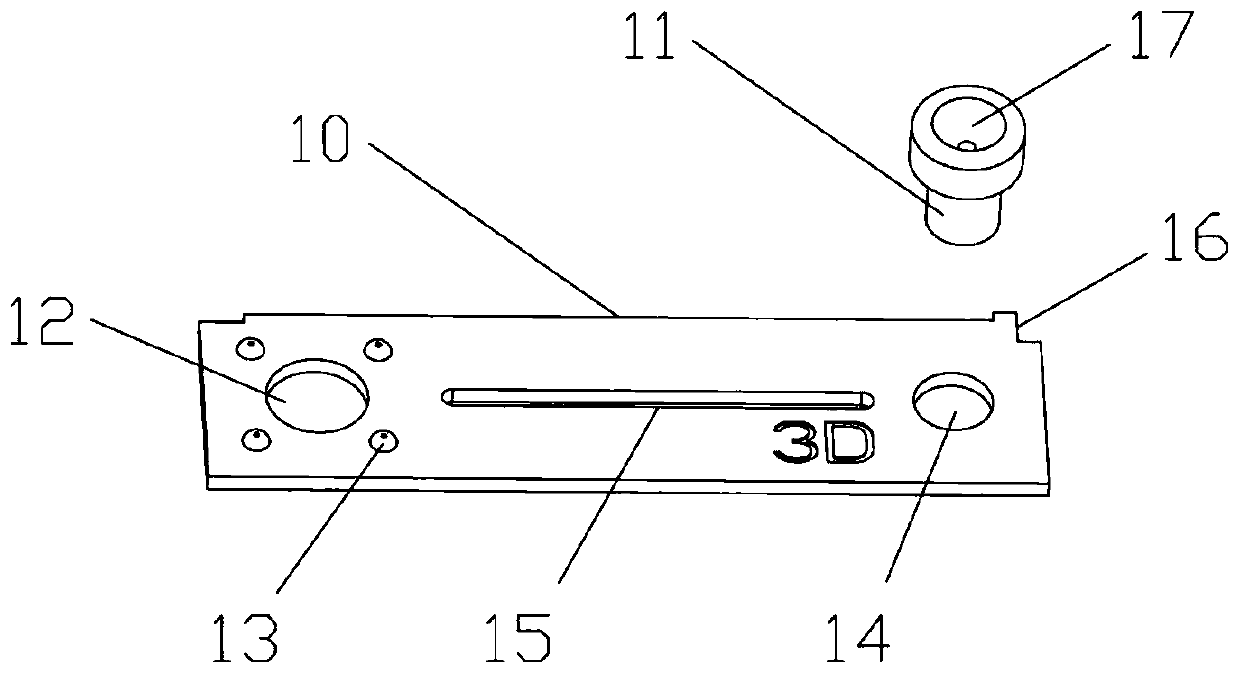

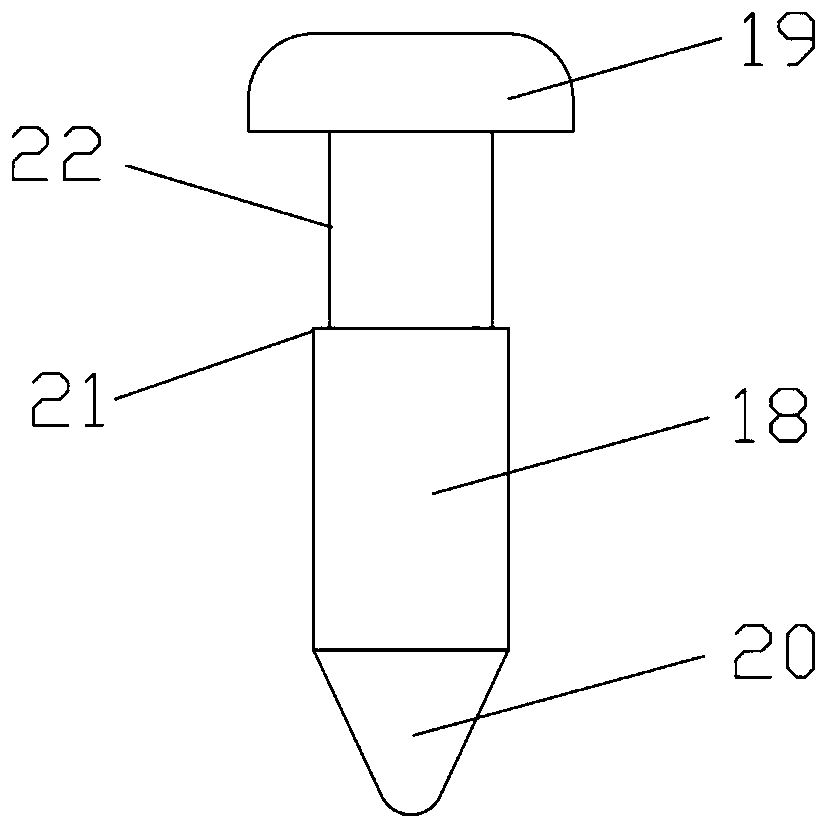

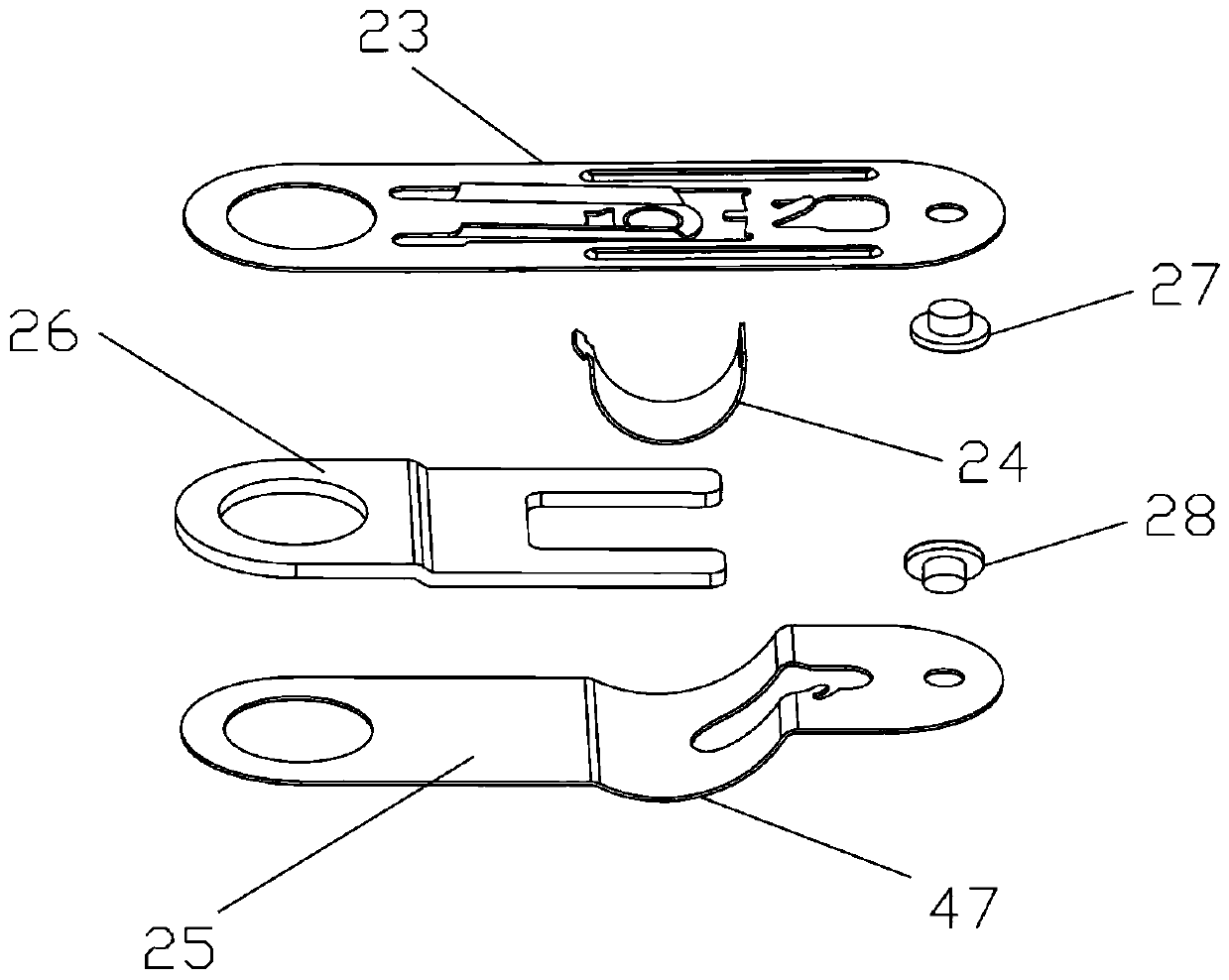

[0035] Such as figure 1 and figure 2As shown in the present invention, a floating adjustable temperature controller with over-temperature protection contacts includes a temperature adjustment device, a transmission limit insulator 18, a temperature-sensitive over-temperature protection component, a contact floating switch component, an insulation The component and the riveted fixing component are correspondingly provided with a thermostat composed of a temperature-sensing over-temperature protection component including a temperature-sensing multi-metal sheet 10, and a transmission fusible alloy column 11 is arranged on the temperature-sensing multi-metal sheet 10, and the transmission fusible alloy column 11 is connected For the transmission limit insulator 18, the transmission limit insulator 18 is connected to the contact floating switch assembly. When the transmission fusible alloy column 11 reaches the melting point, it melts, so that the transmission limit insulator 18 l...

Embodiment 2

[0061] Such as Figure 12 As shown, the difference between the second example and the first example is that the first example adopts a vertical thermostat, and the second example uses a bridge thermostat, and the difference lies in:

[0062] 1) The vertical platen is short, with only one fixing hole; the bridge platen is about twice as long as the vertical platen, and has mounting and fixing holes at both ends;

[0063] 2) The temperature-sensing multi-metal sheet of the vertical thermostat is fixed at one end of the hollow rivet, and the temperature-sensing multi-metal sheet of the bridge-type thermostat is fixed at the other end of the pressure plate.

[0064] Except for the slightly different structures above, the rest of the structures are the same as those in Embodiment 1, and the working principles are also the same, so no repeated description is given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com