A linkage type three-step self-detection punching device

A punching device and self-checking technology, applied in the field of linked three-step self-checking punching devices, can solve the problems of punching waste falling off, waste falling on the ground, etc. Fixed, overhauled full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

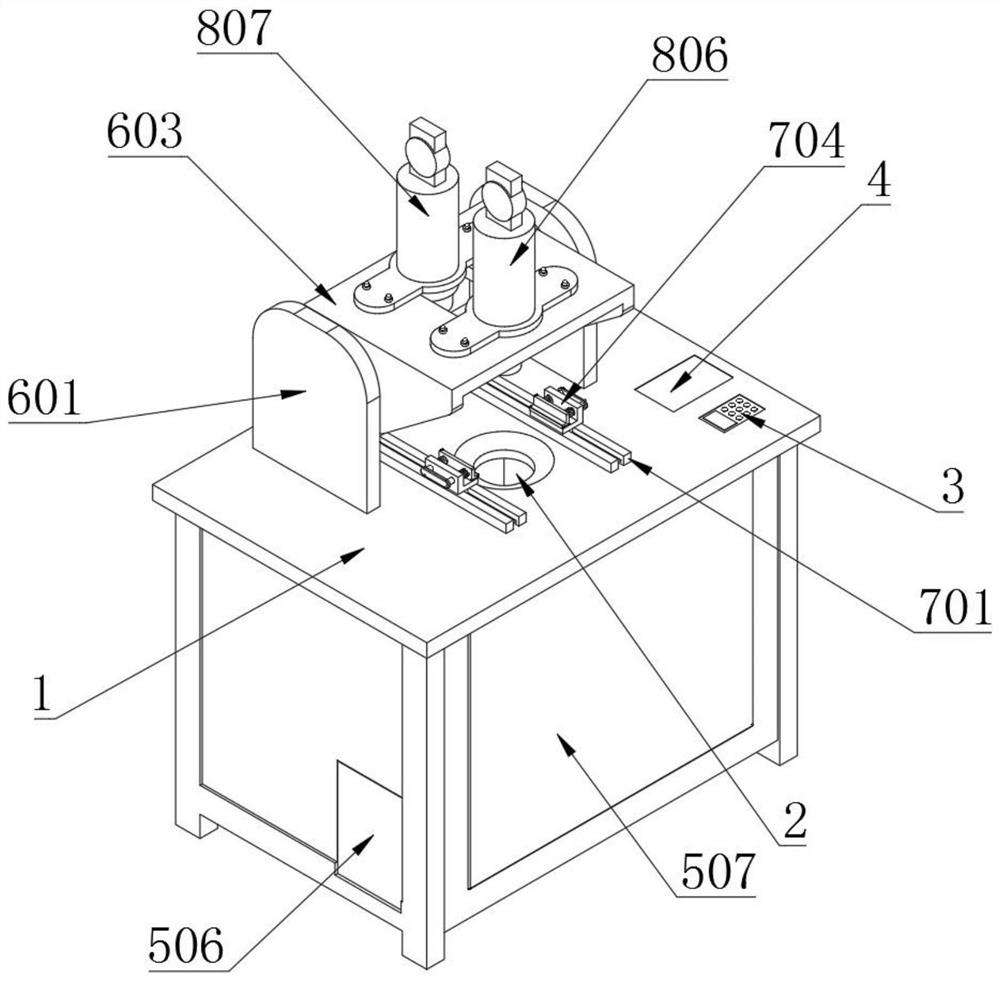

[0047] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a linkage type three-step self-detection punching device, including a frame 1, a leak hole 2 is opened at the center of the top of the frame 1, and the top of the frame 1 corresponds to the side of the leak hole 2 A control switch 3 is embedded in the position, and a display screen 4 is embedded in the position corresponding to the side of the control switch 3 at the top of the rack 1;

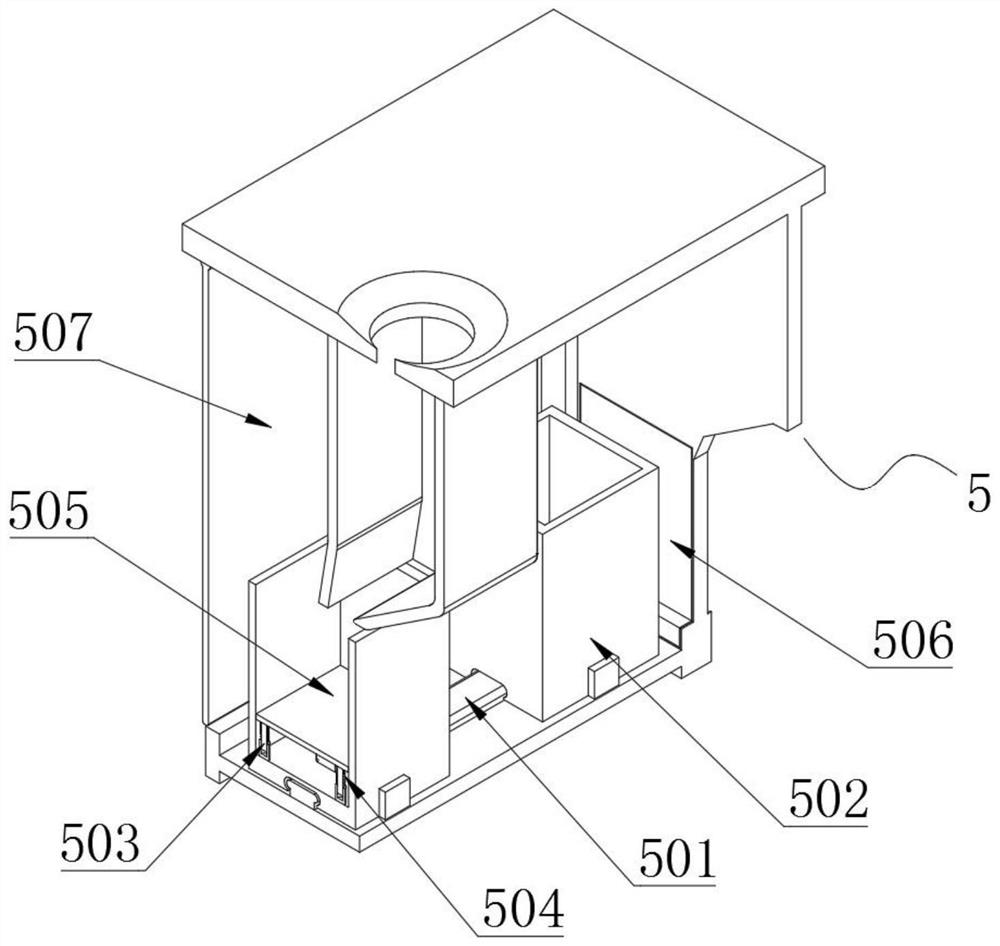

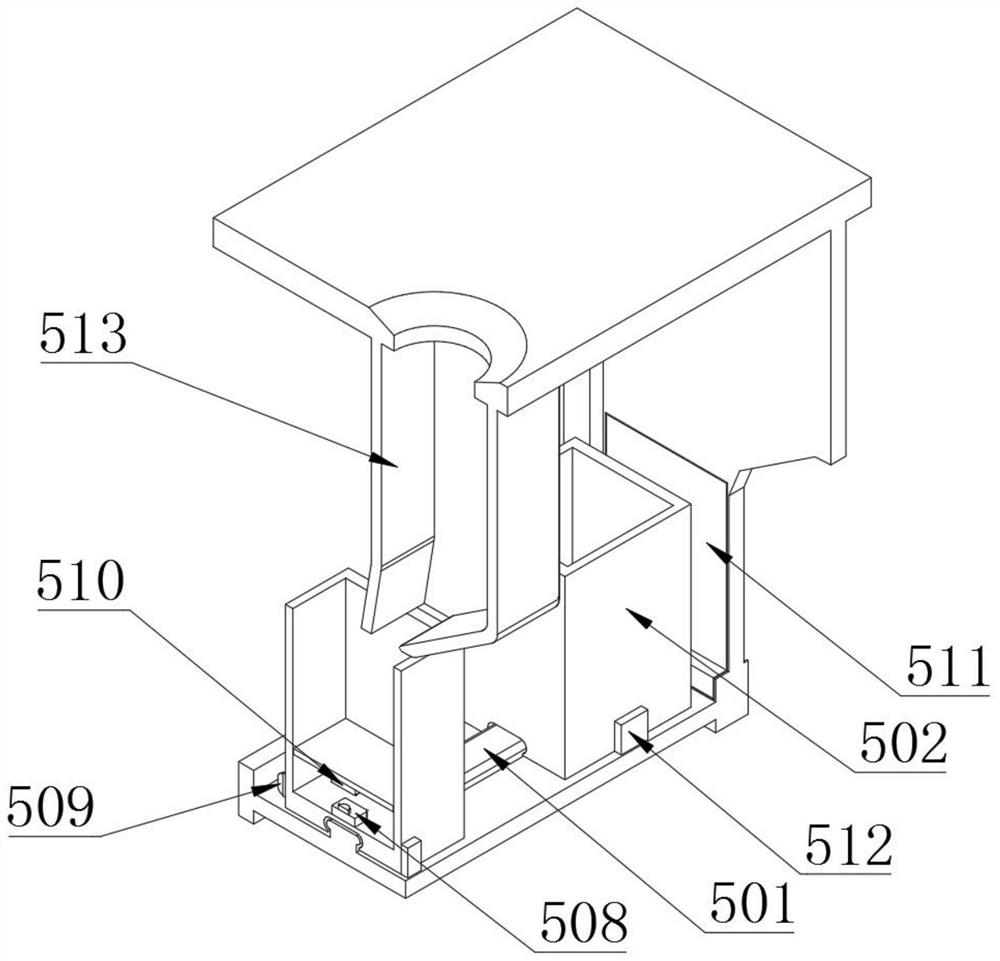

[0048] The inside of the frame 1 is equipped with a convenient material receiving mechanism 5, which includes a slide rail 501, a storage bucket 502, a telescopic rod 503, a supporting spring 504, a supporting plate 505, a discharge cover 506, a transparent protective cover 507, and a contact switch 508, LED lamp 509, pressing plate 510, placement cover 511, storage battery 512 and hopper 513;

[0049] The bottom inner wall of the frame 1 is connected with a slide rail 501, the top of the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com