Composite copper plate

A composite board and copper board technology, which is applied in layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of ignoring the material properties of copper boards, the inability to continue to use, and the easy damage of copper boards, so as to achieve a complete and seamless overall structure , improve performance integration, avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

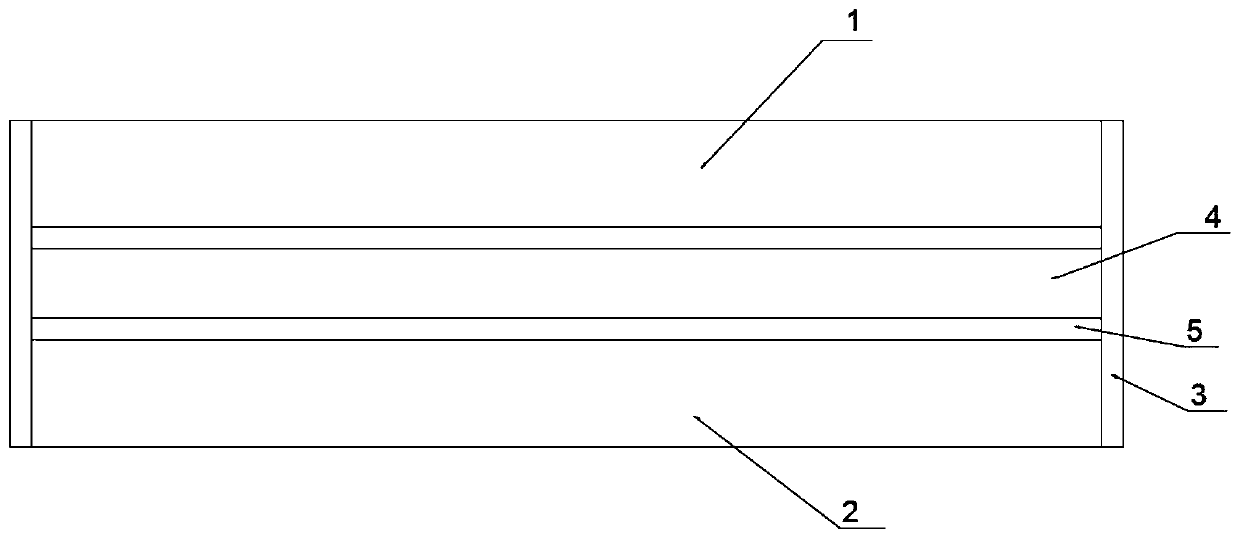

[0018] Such as figure 1 Shown:

[0019] A composite copper plate, comprising an upper plate 1, a lower plate 2, a side frame 3, an inner material 4 and solder 5, the upper plate 1 and the lower plate 2 are copper plates, the side frame 3 is a copper plate, the upper plate An inner material 4 is set between the inner material 4 and the lower plate 2, the inner material 4 is steel, a solder 5 is set between the inner material 4 and the upper plate 1, and a solder 5 is set between the inner material 4 and the lower plate 2, The size of the upper plate 1, the lower plate 2 and the inner material 4 are the same, the side frame 3 is surrounded by the upper plate 1, the lower plate 2 and the inner material 4, and the height of the side frame 3 is equal to the upper plate 1, the lower plate 2 and the thickness of the inner material 4 composite board.

[0020] The inner ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com