Material blocking device for optical coupling laser marking machine

A technology of laser marking machine and material blocking device, which is applied in the direction of printing device, printing, etc., can solve the problems of damaging the track structure, difficult adjustment, and reducing strength, etc., and achieves the effect of flexible installation, convenient position adjustment, and no damage to the track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

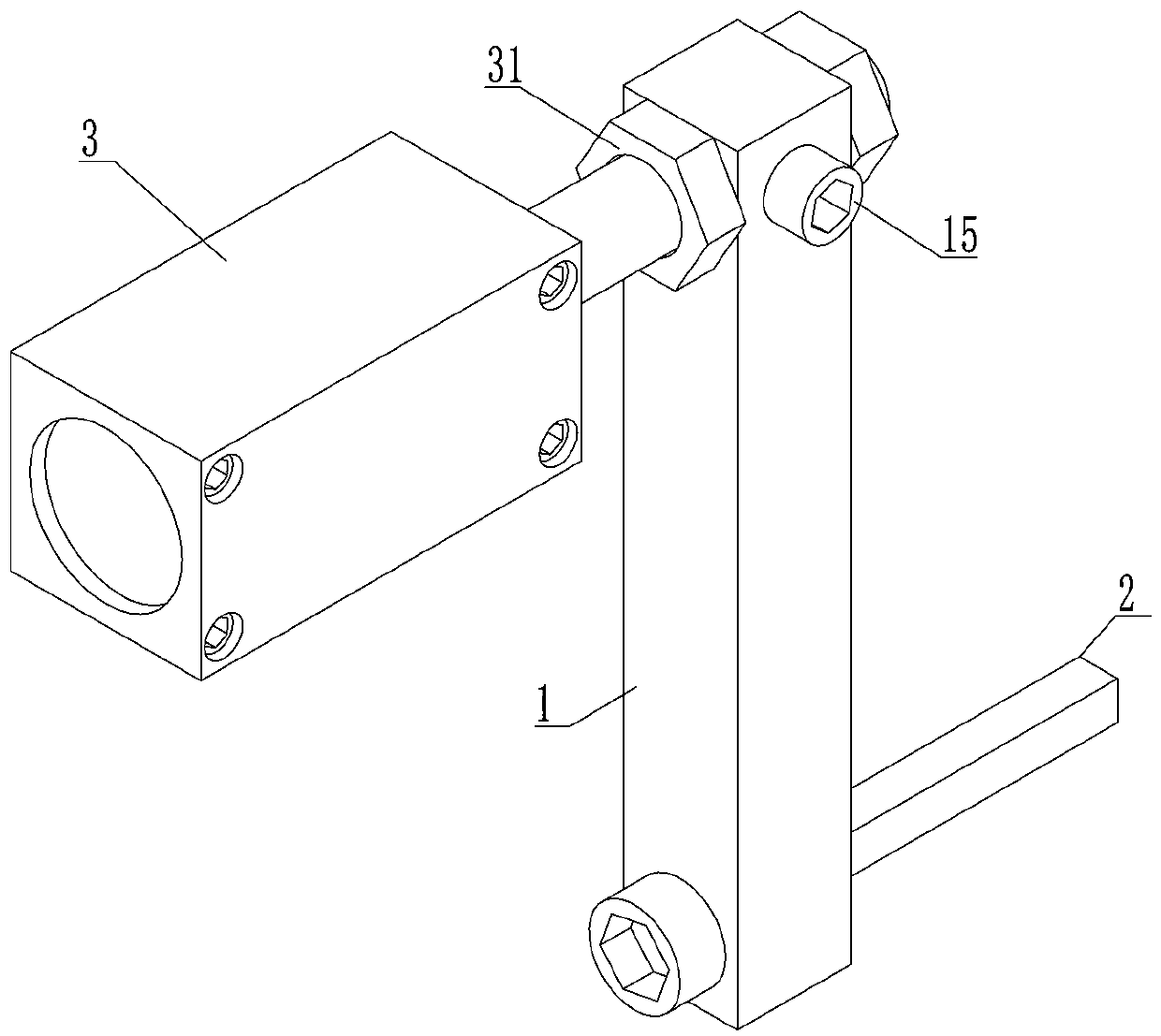

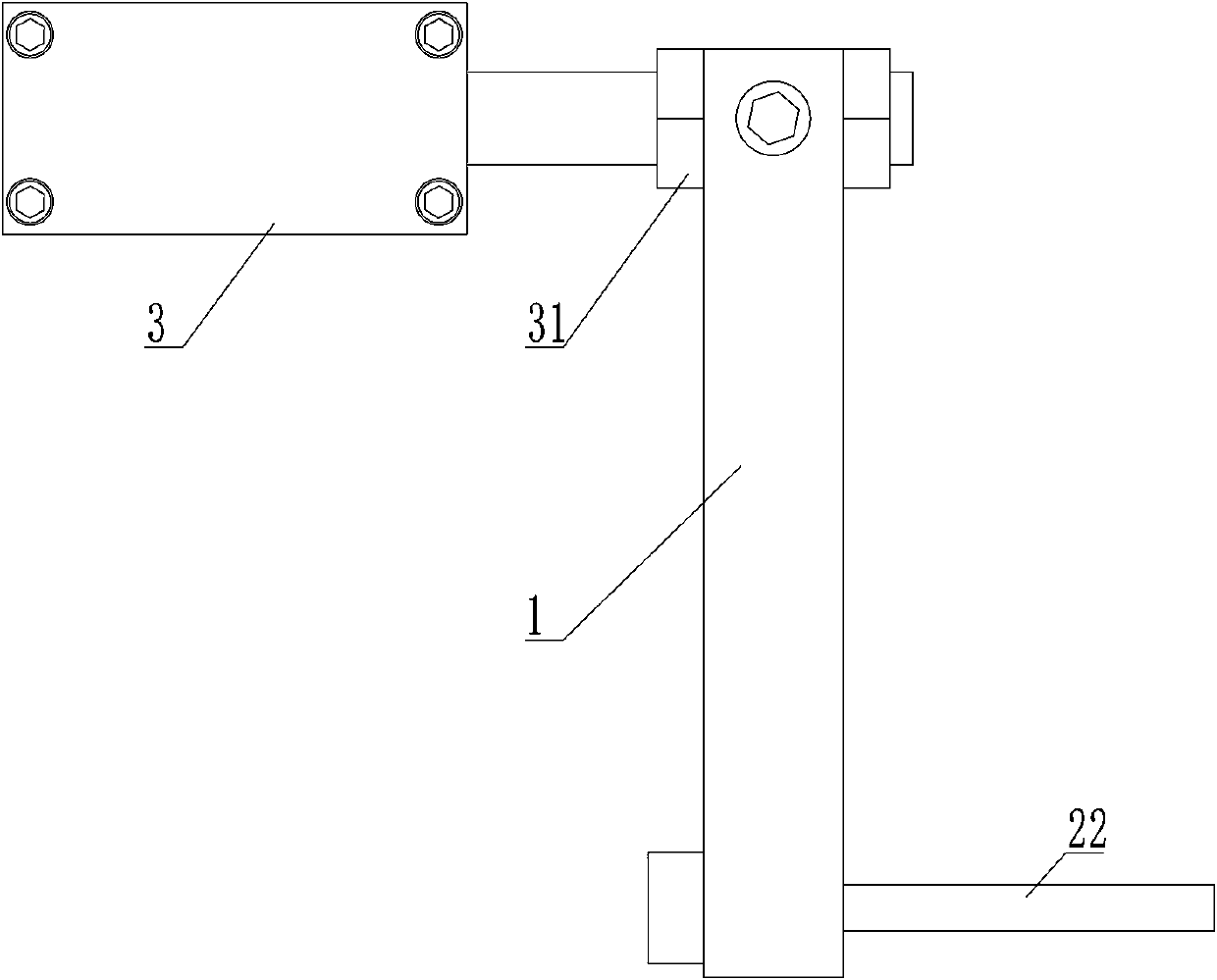

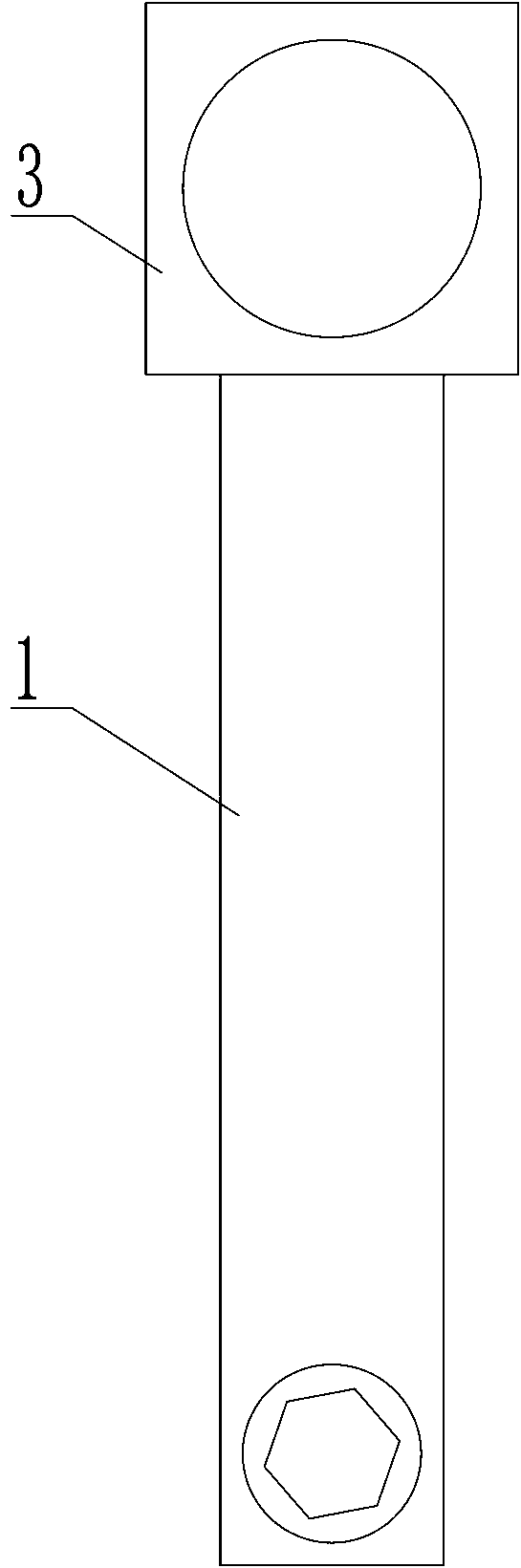

[0027] Such as Figure 1~Figure 6 Among them, an optocoupler laser marking machine stopper device, which includes a vertical rod 1, a stopper rod 2 and a telescopic mechanism 3; the two ends of the vertical rod 1 are respectively connected with the stopper rod 2 and the telescopic mechanism 3; The stopper rod 2 and the telescopic mechanism 3 are located on the same side of the vertical rod 1 or on the two sides corresponding to each other; Tightly connected; the stopper rod 2 and telescopic mechanism 3 on the corresponding two sides are connected with the vertical rod 1 to form a "Z" shape structure. The structure is simple, and the vertical rod 1 is connected to the stopper rod 2 and the telescopic mechanism 3. The stopper rod 2 and the telescopic mechanism 3 are movably connected to the vertical rod 1. The vertical rod 1 is driven to move along the stopper rod 2 through the telescopic mechanism 3. The stopper rod 2 Cooperate with the groove of the marking machine track to b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap