Straddle type single-rail track beam linear adjustment system and adjustment method

A straddle-type monorail and adjustment system technology, which is applied to the straddle-type monorail track beam line adjustment system and the field of adjustment, can solve the problems of the change of the line shape of the track beam, the inability to realize small line adjustment, time-consuming and labor-intensive and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

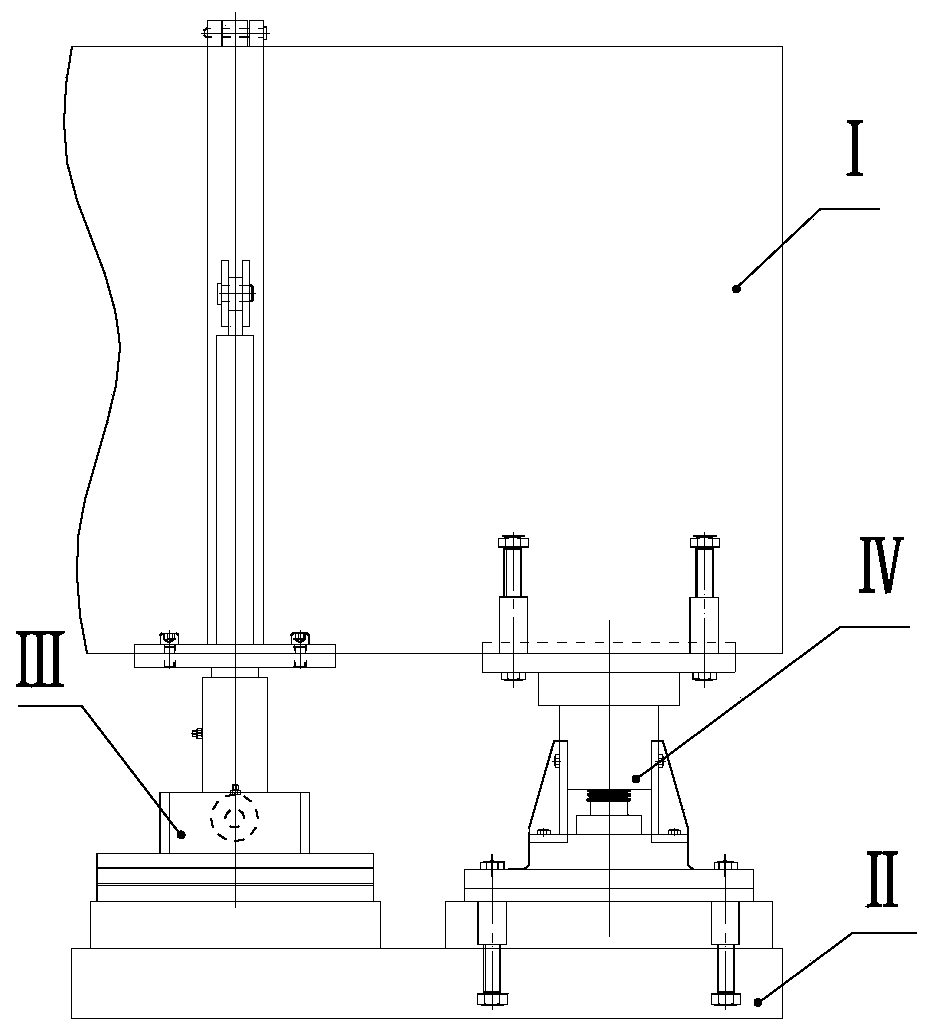

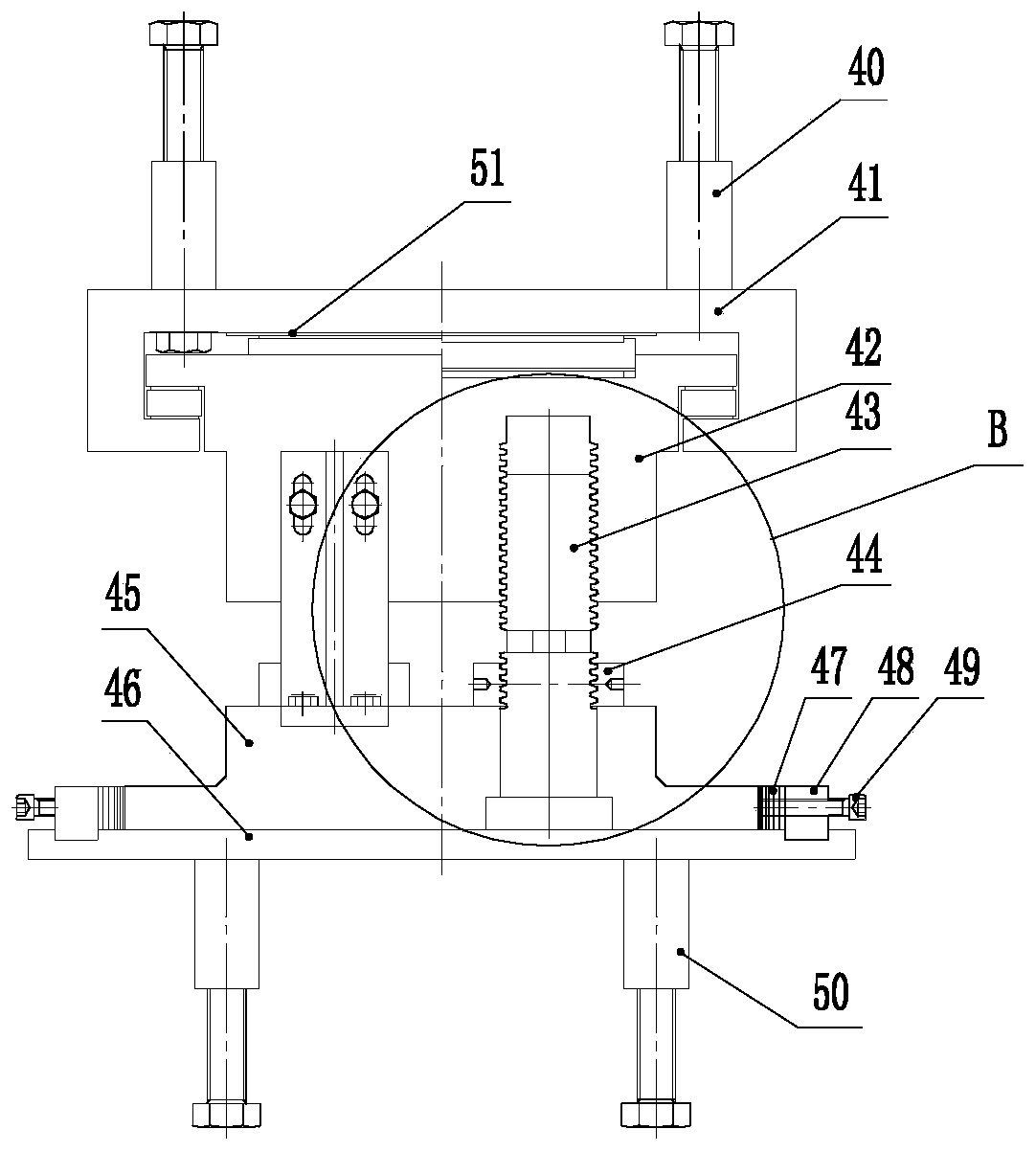

[0067] A straddle-type monorail track beam line adjustment system, including a track beam and a straddle-type monorail support IV, and the straddle-type monorail support includes an upper seat plate 41, a lower seat plate 42, a lower base 45 and a lower bottom plate 46 , the straddle-type monorail support is anchored to the track beam I through the upper anchor bolt 40, and is anchored to the cover beam II through the lower anchor bolt 50; the straddle-type monorail track beam alignment adjustment system also includes a three-dimensional Adjustment device III;

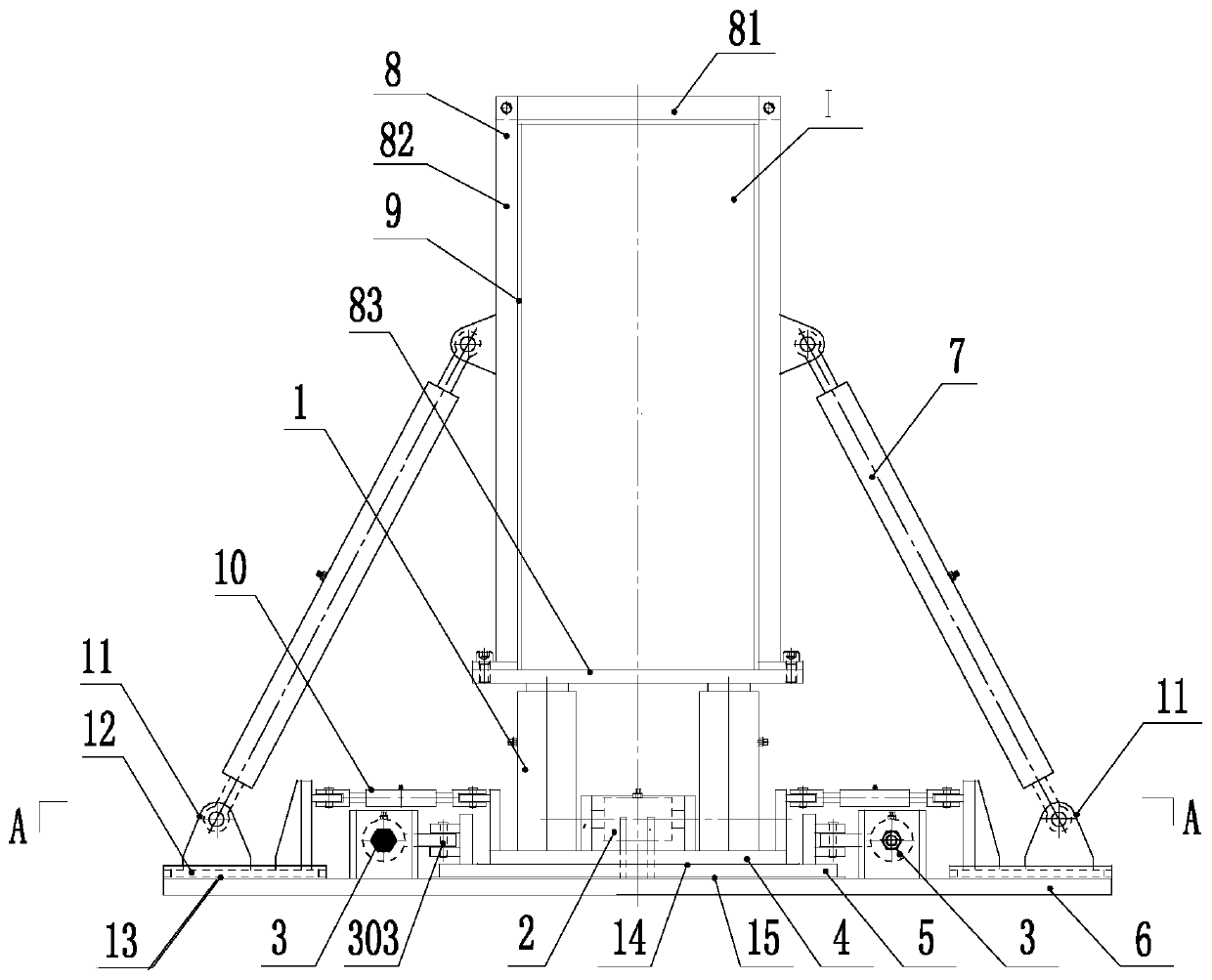

[0068] The three-dimensional adjustment device includes a base 6 and a horizontal sliding seat 4 installed on the base, a longitudinal sliding seat 5, a vertical adjustment mechanism 1, a horizontal adjustment mechanism 2 and a longitudinal adjustment mechanism 3, wherein the horizontal sliding seat 4 is larger than the longitudinal sliding seat 5 Small, the longitudinal sliding seat 5 is smaller than the base, the hor...

Embodiment 2

[0079] A method for adjusting the alignment of a straddle-type monorail track beam, which is a method for adjusting the alignment of a straddle-type monorail track beam by using the alignment adjustment system for a straddle-type monorail track beam described in Embodiment 1, including Follow the steps below:

[0080] S1. Set up a set of straddle-type monorail supports at both ends of each span track beam, and install a set of three-dimensional adjustment devices next to each set of straddle-type monorail supports:

[0081] S11. The three-dimensional adjustment device is arranged between the track beam I and the cover beam II, the base is placed on the top of the cover beam, and the vertical hydraulic jack is aligned with the bottom of the track beam;

[0082] S10. Wrap the anti-overturning support of the three-dimensional adjustment device around the track beam, and a flexible rubber cushion 9 is provided between the anti-overturning support and the track beam;

[0083] S13....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com