Electric connector

An electrical connector and electrical connection technology, applied in the direction of connection, fixed connection, circuit, etc., can solve the problem that the chip module is easy to cause warpage, and achieve the effect of avoiding warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

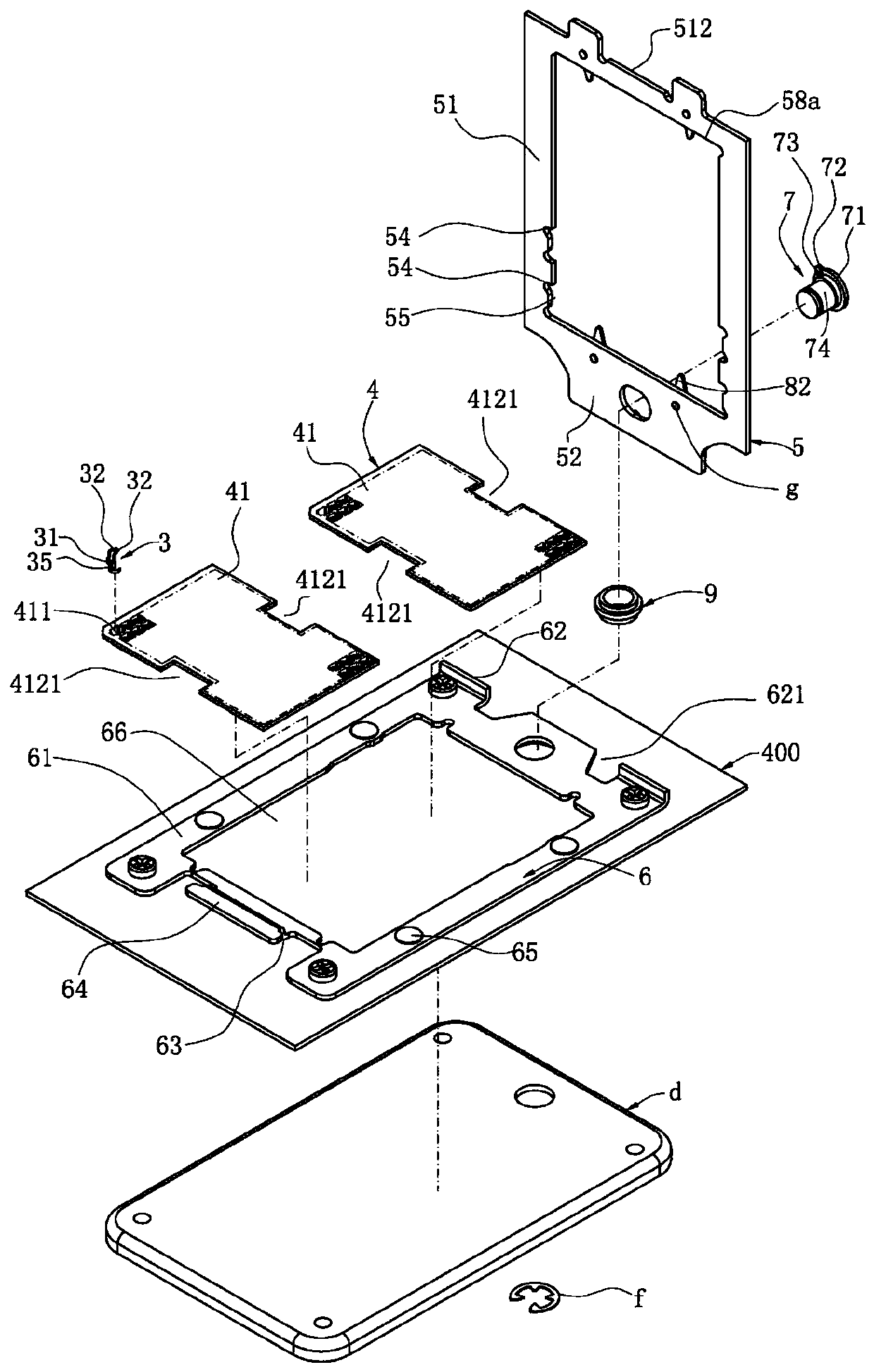

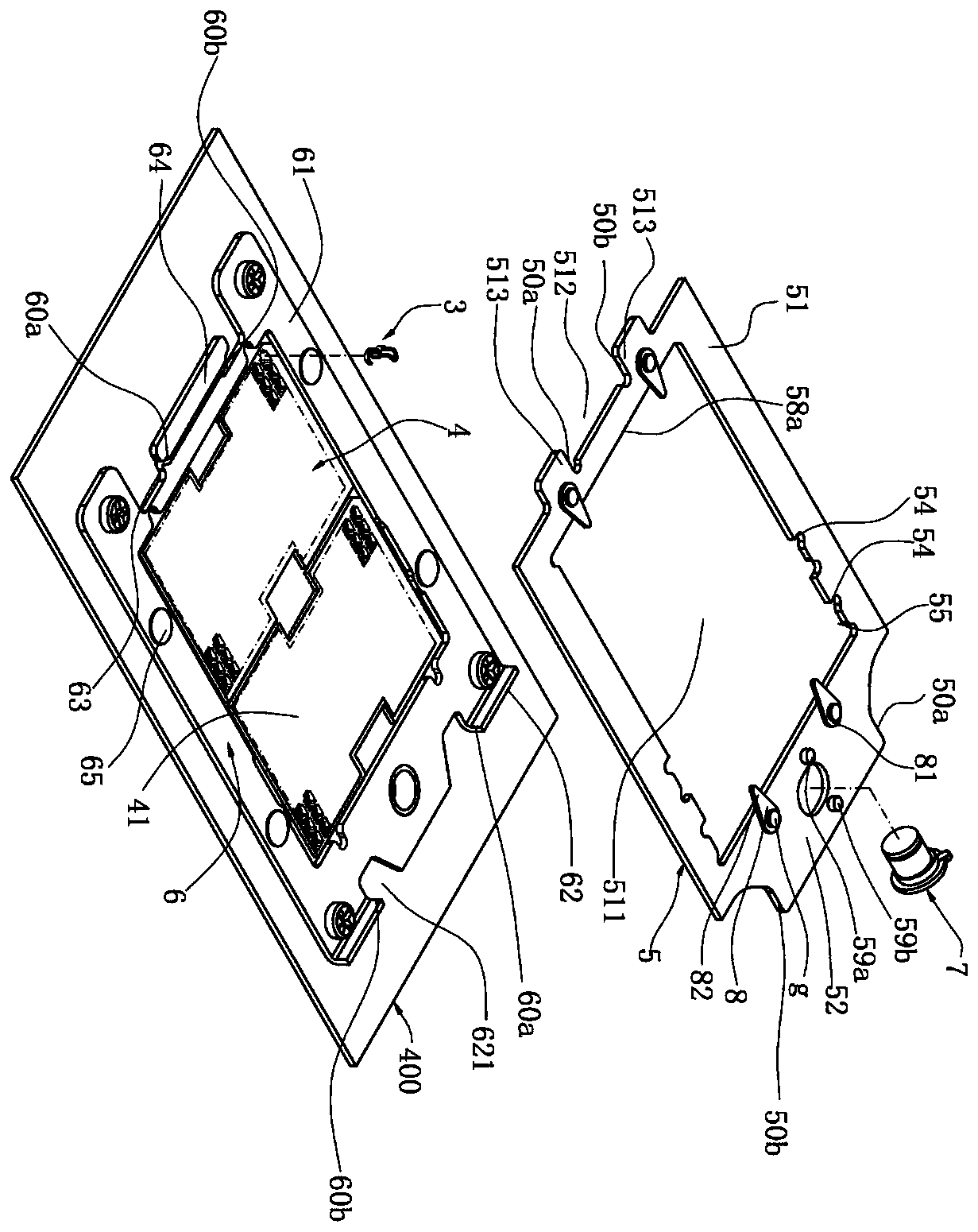

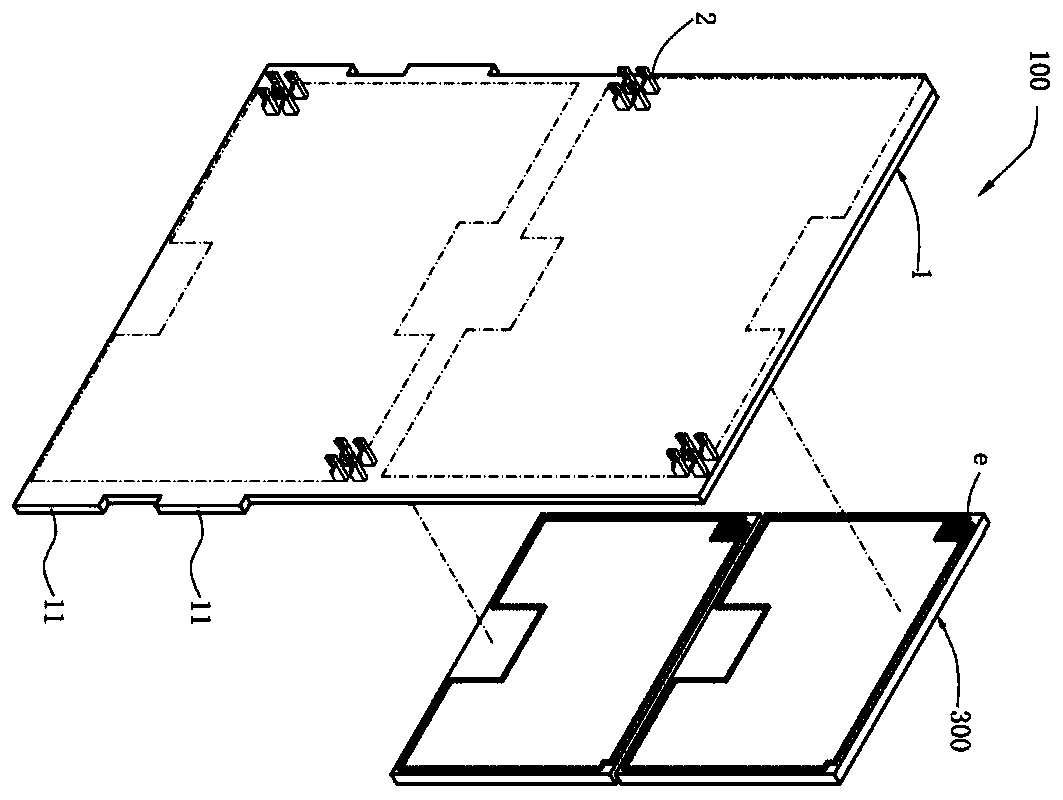

[0051] As shown in Figure 1-19, the first embodiment of the electrical connector 200 of the present invention, the electrical connector 200 is electrically connected to a mating plug 100 and a circuit board 400, the mating plug 100 includes a substrate 1 and a device A chip module 300 is carried on the upper surface of the substrate 1 and electrically connected to the substrate 1 and protrudes downward from the plurality of conductive parts 2 of the substrate 1; the electrical connector 200 includes a An insulating body 4; a plurality of terminals 3 accommodated in the insulating body 4; a cover 5, which is set on the insulating body 4 and can move horizontally back and forth relative to the insulating body 4; a driving member 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com