A rapid-heating and energy-saving small-sized can heating machine

A rapid heating, small-scale technology, applied in heating devices, cooking utensils, household appliances, etc., can solve problems such as heat loss, achieve fast heating speed, small footprint, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

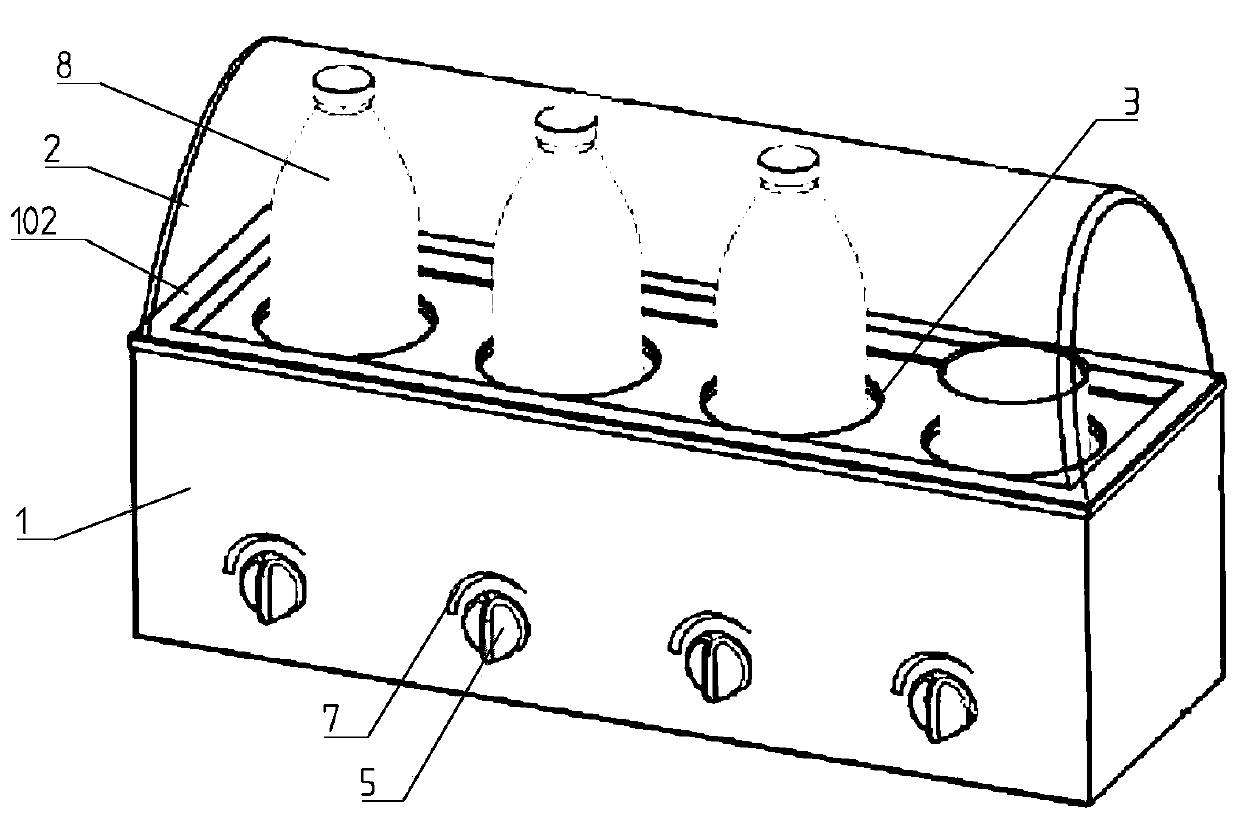

[0028] See Figure 1-2 , in order to solve the above problems, the present application discloses a fast heating and energy-saving small hot pot machine, including

[0029] The casing 1 includes an accommodating cavity surrounded by metal or non-metallic materials, legs or rollers are installed on the bottom of the casing 1 , and an upper opening 102 is formed above it.

[0030] The heat preservation cover 2 is movably connected to the upper opening 102 of the casing 1, and covers the upper opening 102 of the casing; specifically, the heat preservation cover 2 is an arc-shaped cover body. The sides of the opening are hinged, and the other end of the cover is preferably equipped with a handle, which can be opened by holding the handle to lift up the cover and turn it to expose the upper opening 102 .

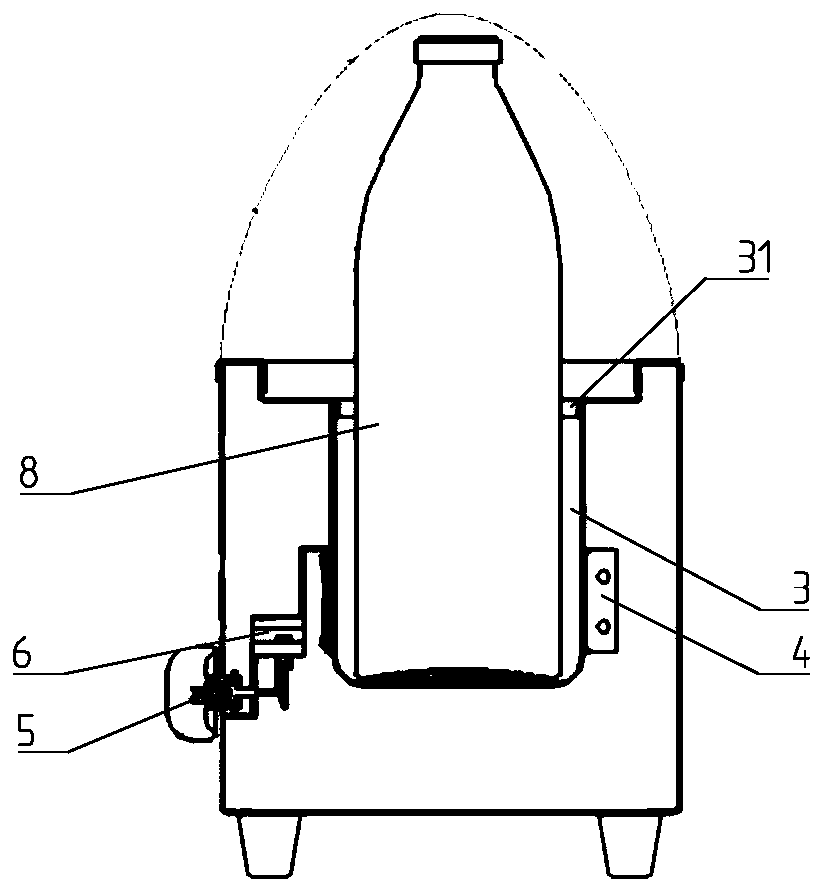

[0031] Heating cavity 3 is located in the casing 1 and is provided with at least one (in consideration of the space occupied, the application is preferably four), the heating cav...

Embodiment 2

[0037] See image 3 , the hot pot machine in Embodiment 1 can well solve the problems in the prior art, but its heating speed is not fast enough, and because the lower part of the beverage in the tank is in contact with the heating liquid during the heating process, it is first heated , and then it can be transferred to the upper part of the beverage, which will cause the uneven temperature of the upper and lower parts of the beverage in the heated tank. In order to solve this technical problem, the difference between this embodiment and the first embodiment is that an ultrasonic device 10 is provided at the bottom of the heating chamber 3 , and the sound wave output end of the ultrasonic device 10 is attached to the bottom of the heating chamber 3 .

[0038] Specifically, the ultrasonic device 10 includes an ultrasonic driver and an ultrasonic vibrator, and the ultrasonic vibrator is fixed at the bottom of the heating chamber, so that when the hot pot machine heats the bevera...

Embodiment 3

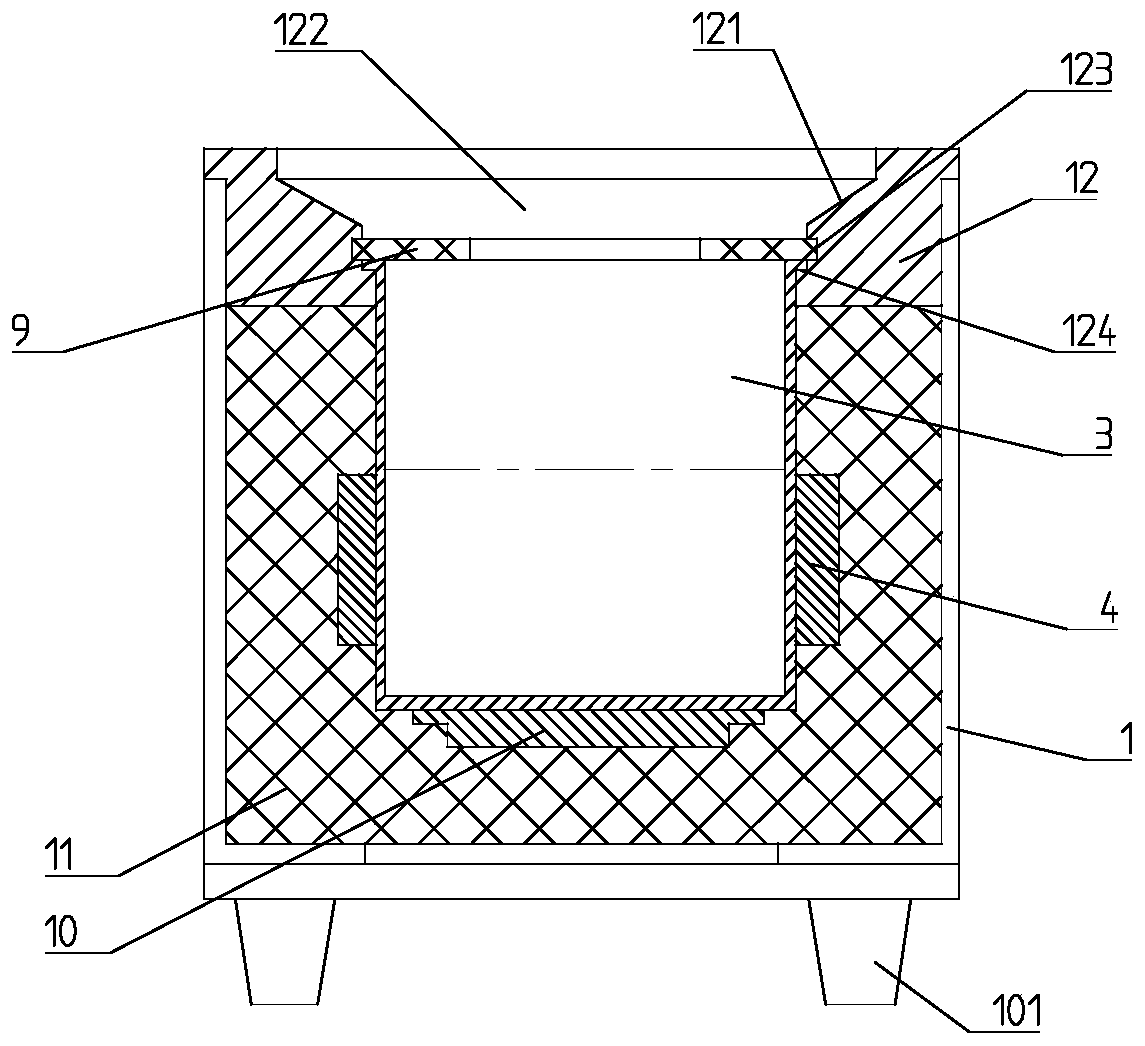

[0041] See Figure 3-4 , the heating chamber in embodiment one and embodiment two is an open type, and the liquid in the heating chamber is heated and evaporates faster during the heating process, and the loss is also increased, so it is necessary to add water to the heating chamber frequently; and, if added The amount of water is not properly controlled. If too much water is added, the water will overflow when it is put into a larger tank. If the amount of water added is small, it is difficult for a smaller tank to obtain as large a contact area with water as possible. Thus, the difference between this embodiment and Embodiments 1 and 2 is that a support 12 is fixed at the opening of the casing 1, and a placement channel 122 is provided in the middle of the support 12. The support 12 covers the opening of the casing 1 and only It can be exposed to the outside through the placement channel 122 , and the placement channel 122 is located directly above the heating chamber 3 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com