Swing ball shooting mechanism of marble game machine

A game machine and marble technology, which is used in indoor games, sports accessories and other directions to achieve the effect of improving left and right swing performance, saving effort in manipulation and fast swing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

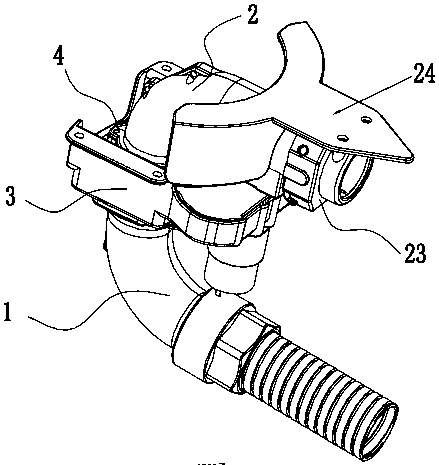

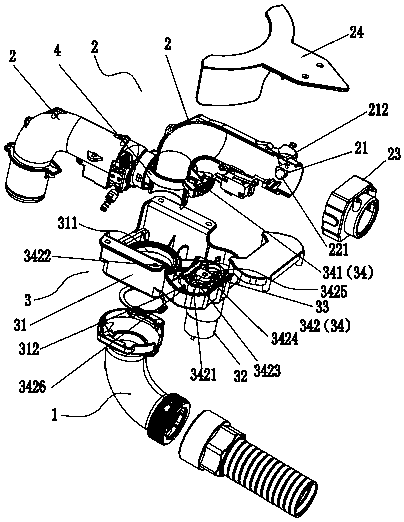

[0027] refer to Figure 1 to Figure 4 The ball shooting mechanism shown in the pinball game machine includes a bead-feeding pipeline 1 and a bead-shooting barrel 2. The bead-shooting barrel 2 is installed correspondingly to the bead-feeding pipeline 1 through a swing device 3. The swing The device 3 is composed of a fixed body 31, a driving motor 32, a driving gear 33 and a driven gear 34. The fixed body 31 is provided with a connection through hole 311, and the bead inlet pipeline 1 is installed below the connection through hole 311. The bead-shooting gun barrel 2 is rotatably installed above the connecting through hole 311 to correspond to the bead-feeding pipeline 1, so that the bead-feeding pipeline 1 and the bead-shooting gun barrel 2 are butted to form a bead-feeding pipeline, and the driving gear 33 is set on a fixed On the body 31, the driven gear 34 is arranged on one side of the bead shooting gun barrel 2 and is located at the corresponding position of the driving ge...

Embodiment 2

[0034] In this embodiment, the driven gear 2 342 is composed of a main body 3421, side meshing teeth 3422 and inner meshing teeth 1 3423. Specifically, the main body has a rectangular structure, and the side meshing teeth 3422 and inner meshing teeth One 3423 is respectively arranged on the parallel sides of the main body 3421, the side meshing teeth 3422 and the driven gear one 341 correspond to form a meshing transmission, and the internal meshing teeth one 3423 corresponds to the driving gear 33 to form a meshing transmission, and the driving gear 33 is a circle Shaped gear, in this embodiment, the drive motor 32 needs to be provided with a device for forward and reverse rotation, such as a one-way switch, and the rest are the same as the above embodiment.

Embodiment 3

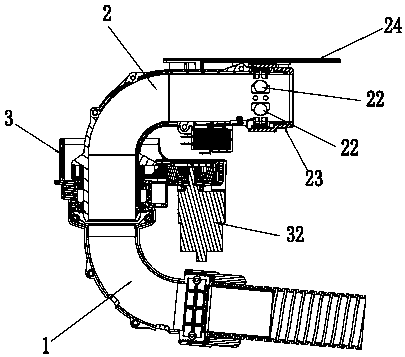

[0036] refer to Figure 5 with Image 6 The technical characteristics of the swing ball shooting mechanism of the pinball game machine shown in this embodiment are: two installation through holes 21 are symmetrically arranged on both sides of the exit position of the ball shooting gun barrel 2 (that is, the position of the bead exit), In order to facilitate processing and production, the installation through holes 21 on both sides are distributed in parallel, and the spring fixing member 23 is a fixing member built in the bead outlet end of the bead shooting gun barrel 2. Specifically, the installation through the bead shooting gun barrel 2 An annular groove 223 is provided on the inner wall at the position of the hole 21, and the described spring fixing member 23 is a fixing member with two semicircular heads protruding from the hole 231, and the fixing member compresses the spring on the annular groove 223. 222 is fixed in the inner cavity 211 of the installation part 212, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com