Stent and stent graft

A stent-graft and fabric technology, applied in the field of tubular organs, can solve the problems of poor followability of curved shape and poor diameter reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0073] Hereinafter, specific embodiments of the present invention will be described in detail.

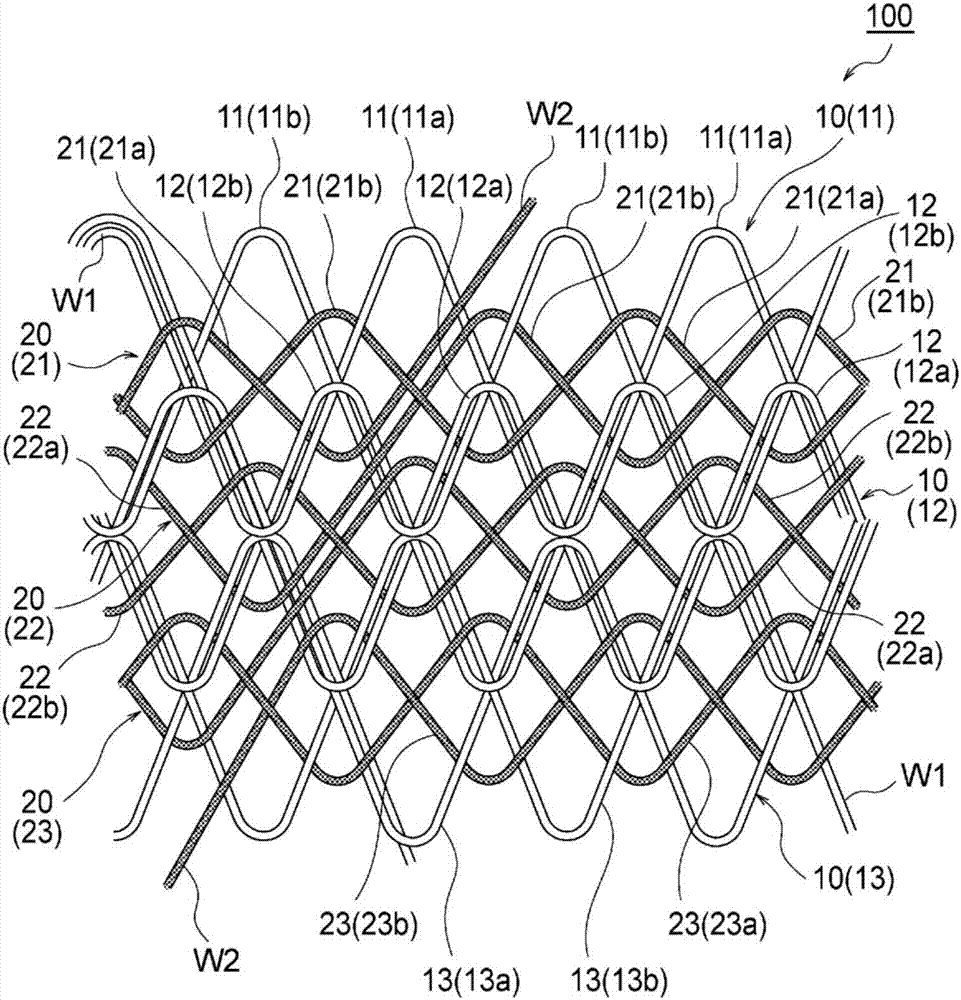

[0074] figure 2 The stent 100 of the present embodiment shown is constituted by: a first fabric structure 10 consisting of a first layer of circumferential cells 11 , a second layer of circumferential cells 12 , and a third layer of circumferential cells 13 adjacent to each other. The circumferential units of each have overlapping parts and are arranged in the axial direction; the second fabric structure 20 is composed of the circumferential unit 21 of the first layer, the circumferential unit 22 of the second layer and the circumferential direction of the third layer The units 23 are arranged axially without overlapping adjacent circumferential units.

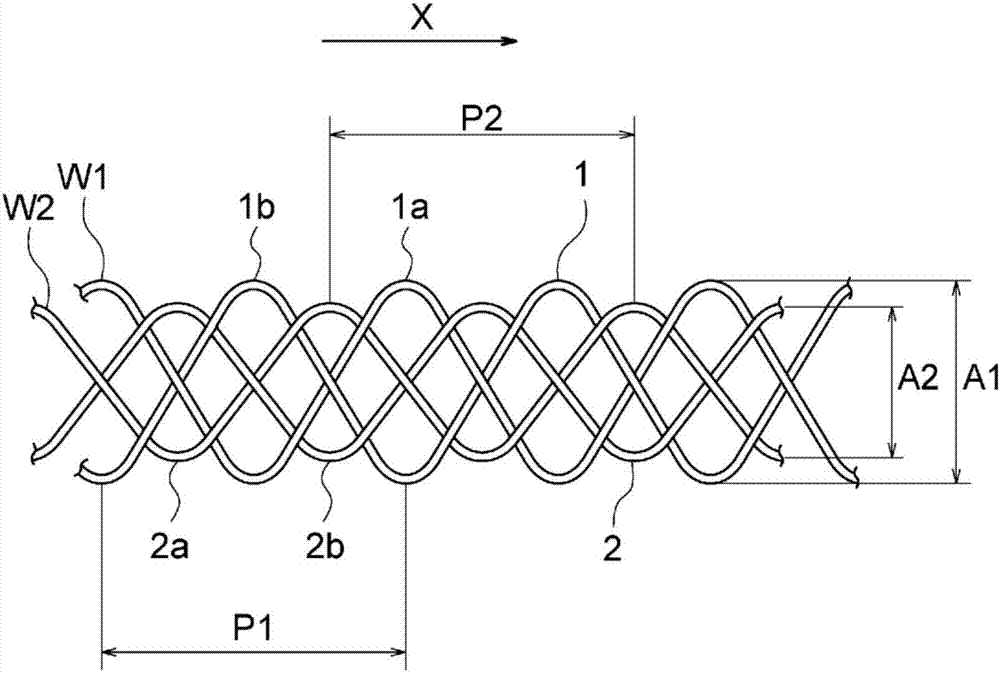

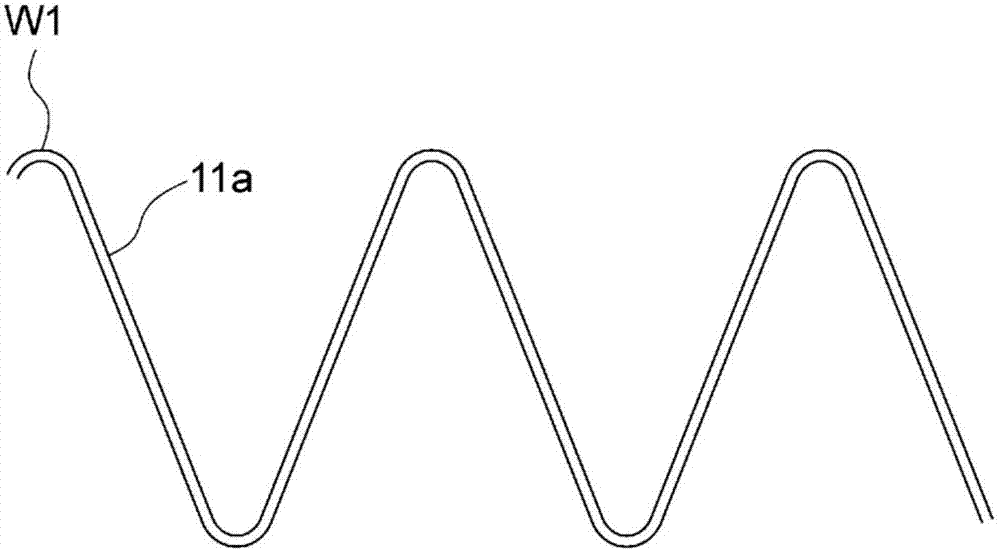

[0075] The circumferential unit 11 constituting the first layer of the first fabric structure 10 is formed by a first loop 11a and a second loop 11b, and the first loop 11a is formed by turning the wire W1 back and forth to the l...

no. 2 approach >

[0112] Figure 4 as well as Figure 5 The stent 200 of the present embodiment shown is constituted similarly to the stent 100 of the first embodiment: a first fabric structure 10 ′, which consists of a first-layer circumferential unit 11 ′, a second-layer circumferential unit 12' and the circumferential unit 13' of the third layer are arranged in the axial direction; the second fabric structure 20' is formed by combining the circumferential unit 21' of the first layer, the circumferential unit 22' of the second layer and The circumferential units 23' of the third layer are arranged along the axial direction.

[0113] In addition, in Figure 5 in, will Figure 4 In the structure shown with figure 2 The parts where the structures shown are different (in the intersecting part of the wire W1 constituting the first fabric structure and the wire W2 constituting the second fabric structure, the front-rear relationship of the wire W1 and the wire W2 is the same as figure 2 The ...

no. 3 approach >

[0123] Figure 6 The shown bracket 300 of this embodiment is composed of a first fabric structure 60 and a second fabric structure 70, and the first fabric structure 60 is formed by combining the circumferential unit 61 of the first layer and the circumferential unit 61 of the second layer. The units 62 are arranged in the axial direction, and the second fabric structure 70 is formed by arranging the circumferential units 71 of the first layer and the circumferential units 72 of the second layer in the axial direction.

[0124] Each of the circumferential units ( 61 , 62 , 71 , 72 ) is composed of two rings that intersect each other in a cross at each linear portion, and one ring advances up and down alternately passing through the other ring.

[0125] Such as Figure 6 As shown, the circumferential unit 61 of the first layer and the circumferential unit 62 of the second layer constituting the first fabric structure 60 are staggered by one pitch (swing width) in the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com