Method for pasting label of customized furniture plate

A labeling and pasting technology, which is applied in the field of custom-made furniture plate pasting labels, can solve the problems of increasing equipment prices, complex equipment structures, and low processing efficiency, and achieve the effects of reducing labor intensity, coexistence of high efficiency and precision, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

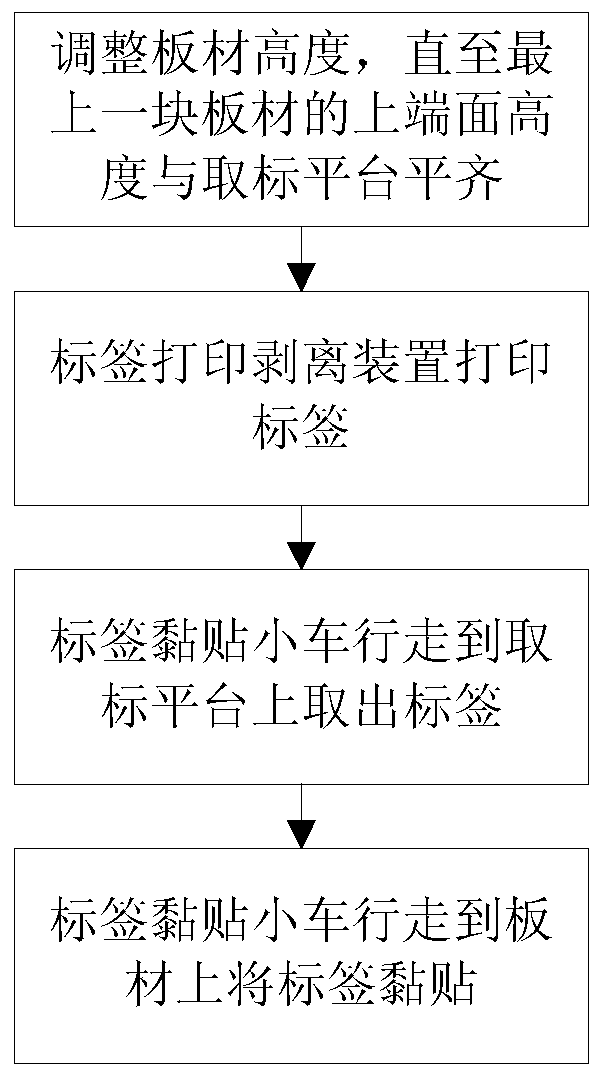

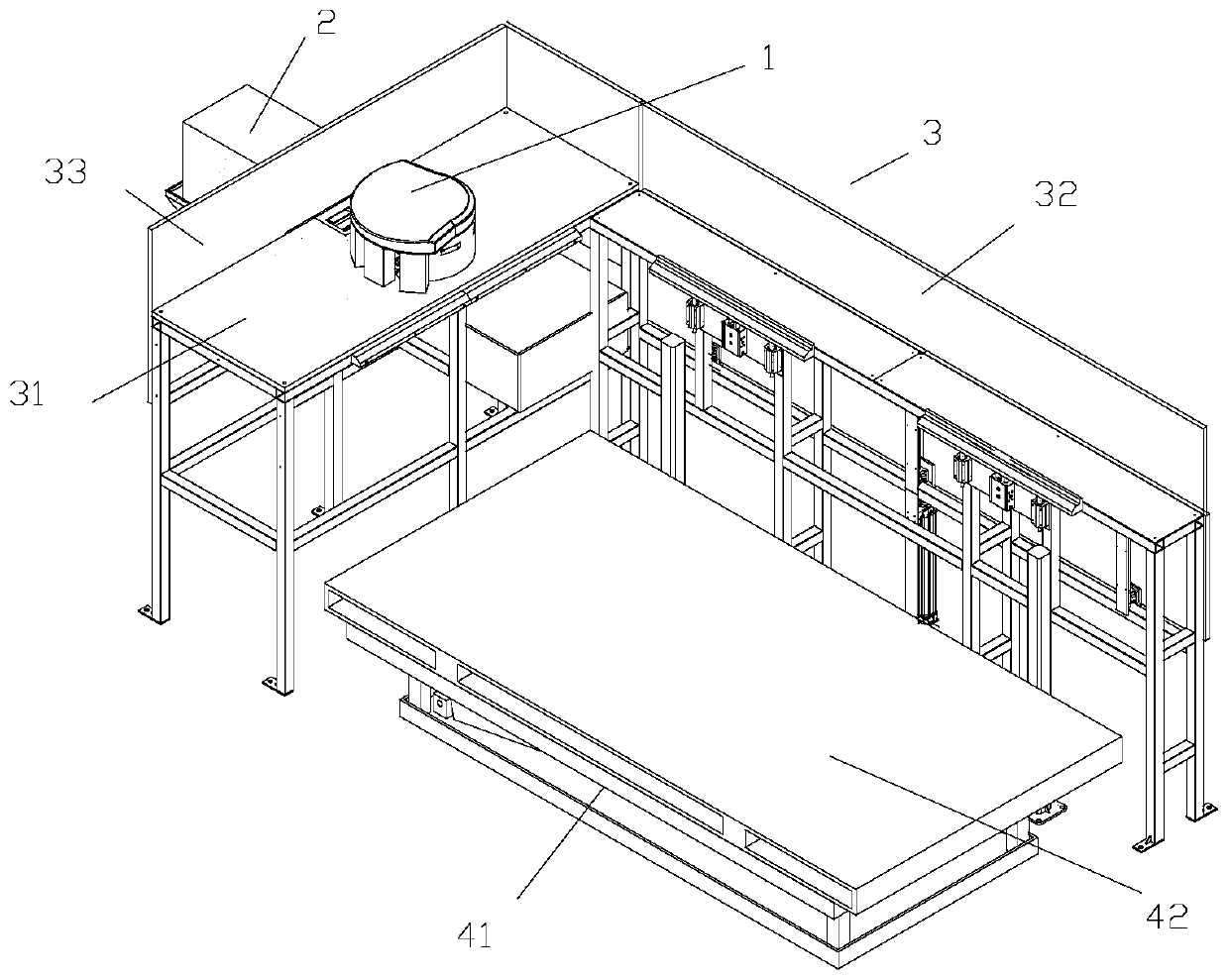

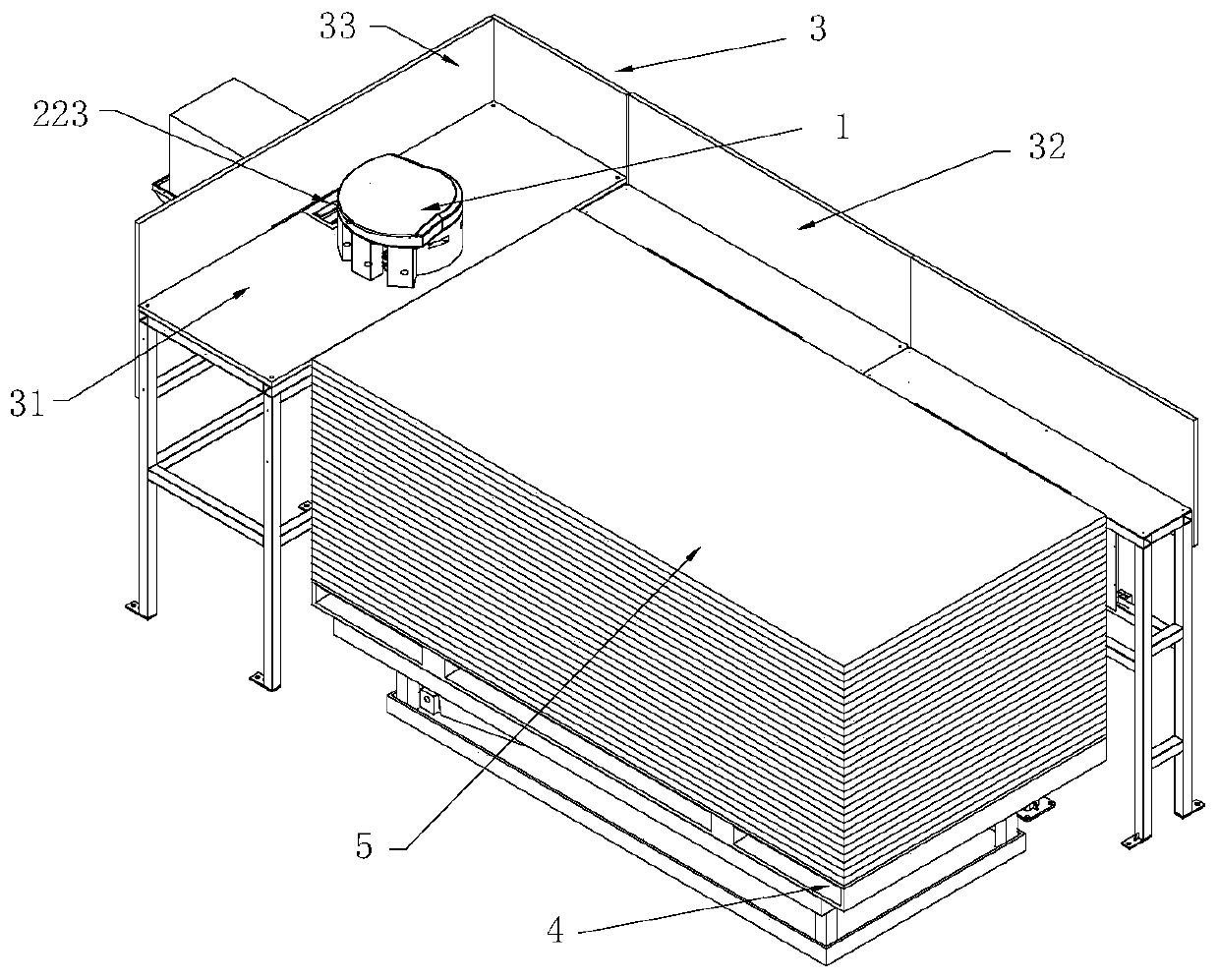

[0059] In this embodiment, a method for customizing the label of the furniture panel, the process is as follows figure 1 As shown, a plate lifting device is provided on one side of the labeling platform of the frame; stack the plates on the plate lifting device to realize the plate lifting; adjust the height of the upper end surface of the last plate to be flush with the labeling platform, so that The labeling platform and the plate together form the movement plane of the label sticking trolley; the label printing and peeling device prints the label, and the label is peeled off from the backing paper and placed on the labeling platform; the label sticking trolley walks on the labeling platform and puts it on the labeling platform Take out the label, and then walk to the board to stick the label.

[0060] The method of the invention can realize the automatic operation of label printing, peeling and pasting, can reduce the labor intensity and labor cost of workers, improve the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com