A kind of pdb board and working method thereof

A working method and motherboard technology, applied in the direction of data processing power supply, measuring device, measuring flow/mass flow, etc., can solve the problems of poor output voltage stability, current overshoot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

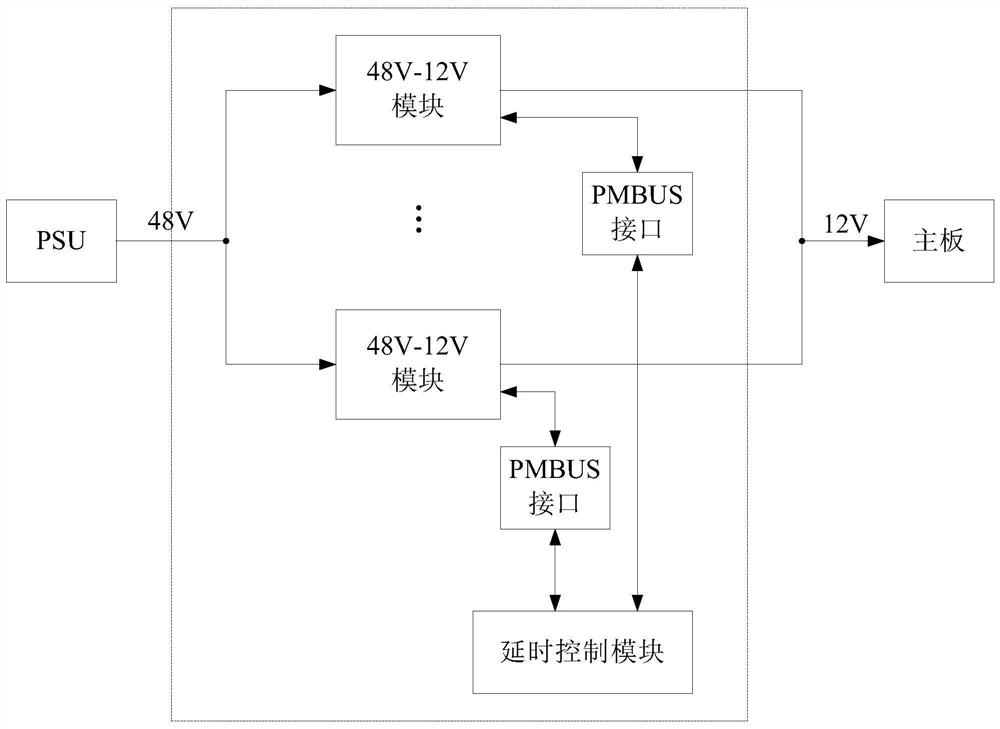

[0052] see figure 1 , figure 1 It is a schematic structural diagram of a PDB board provided by the embodiment of the present application. Depend on figure 1 It can be seen that the PDB board in this embodiment mainly includes: a plurality of 48V-12V modules connected in parallel and a delay control module, where the plurality of 48V-12V modules connected in parallel can be recorded as N 48V-12V modules, where N is Natural number and N≥2, that is, one PDB board includes at least two 48V-12V modules. Among them, any 48V-12V module among the N 48V-12V modules is connected to the delay control module through the PMBUS interface, and the input terminal of any 48V-12V module is connected to the PSU to obtain the 48V voltage from the PSU. The output end of any 48V-12V module is connected to the main board, which is used to supply power to the CPU, memory and hard disk on the main board with the converted 12V voltage.

[0053] In this embodiment, the 48V-12V module is used to conv...

Embodiment 2

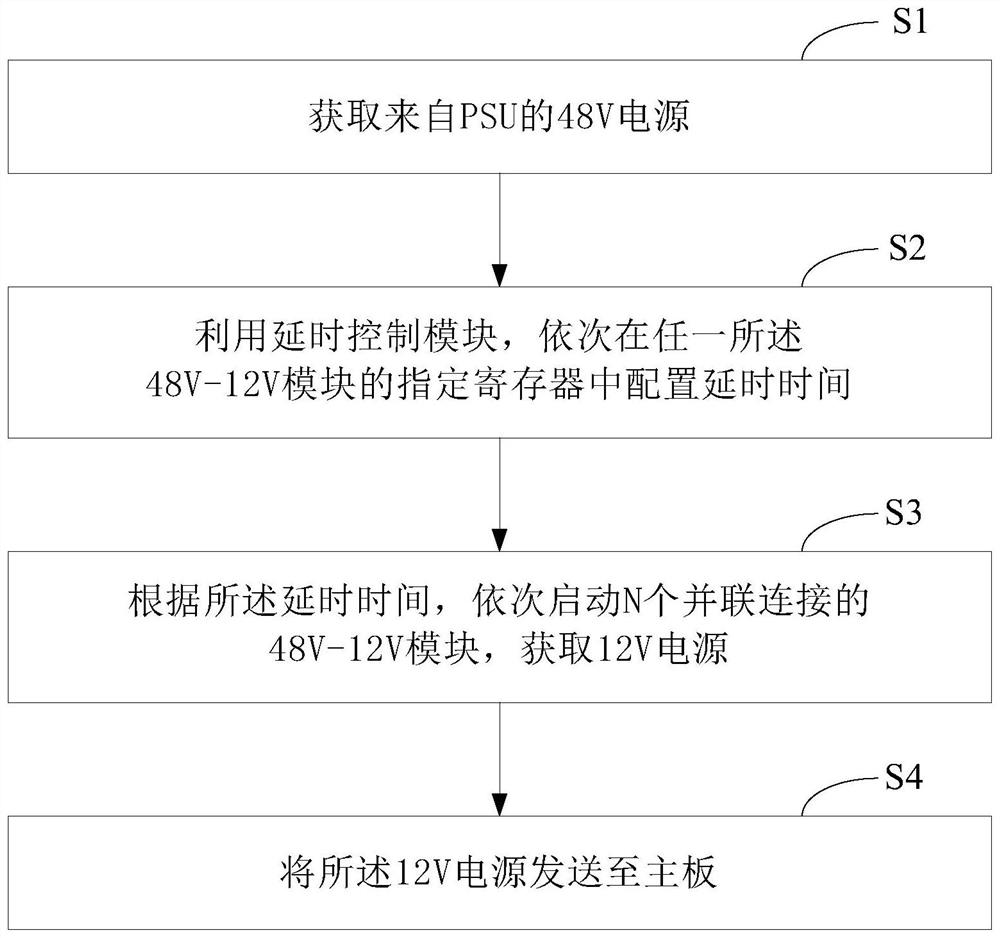

[0065] exist figure 1 and figure 2 On the basis of the illustrated embodiment see image 3 , image 3 It is a schematic flowchart of a working method of a PDB board provided by the embodiment of the present application. Depend on image 3 As can be seen, the working method of the PDB board in the present embodiment comprises the following steps:

[0066] S1: Get 48V from PSU.

[0067] That is: Multiple 48V-12V modules connected in parallel all get 48V from the PSU.

[0068] S2: Use the delay control module to sequentially configure the delay time in the designated register of any 48V-12V module.

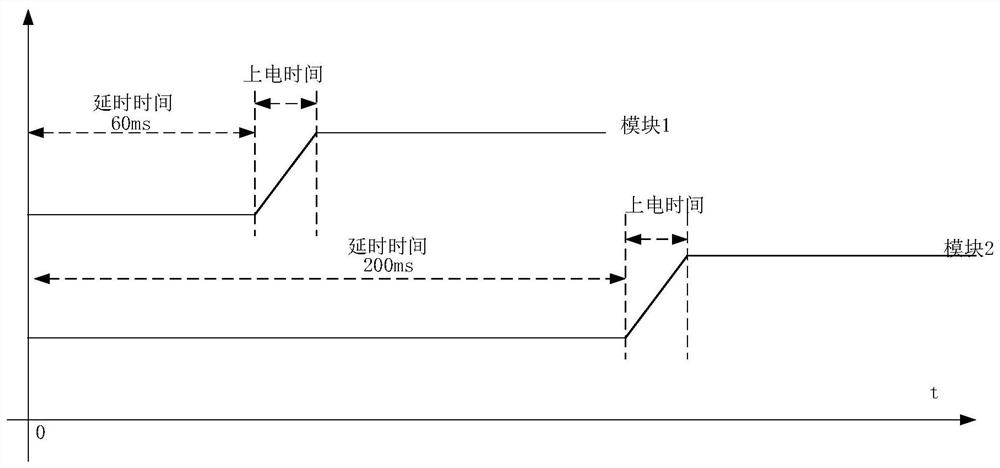

[0069] Wherein, the difference between the delay times of two adjacent 48V-12V modules is equal, and the difference is greater than the power-on time of one 48V-12V module. In this embodiment, the delay times of multiple 48V-12V modules connected in parallel are in an arithmetic sequence relationship.

[0070] Specifically, according to the different configuration methods fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com