Guiding cover type granary with adjustable material paths

A technology for shrouds and granaries, applied to agricultural machinery and implements, applications, harvesters, etc., can solve the problems of corn cobs and corn grains falling on the field, difficulty in picking up corn grains, increased labor and cost, etc., to achieve reduction Effects of dropping fields, reducing manpower and financial resources, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is attached with the manual Figure 1-5 The present invention is described in further detail. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

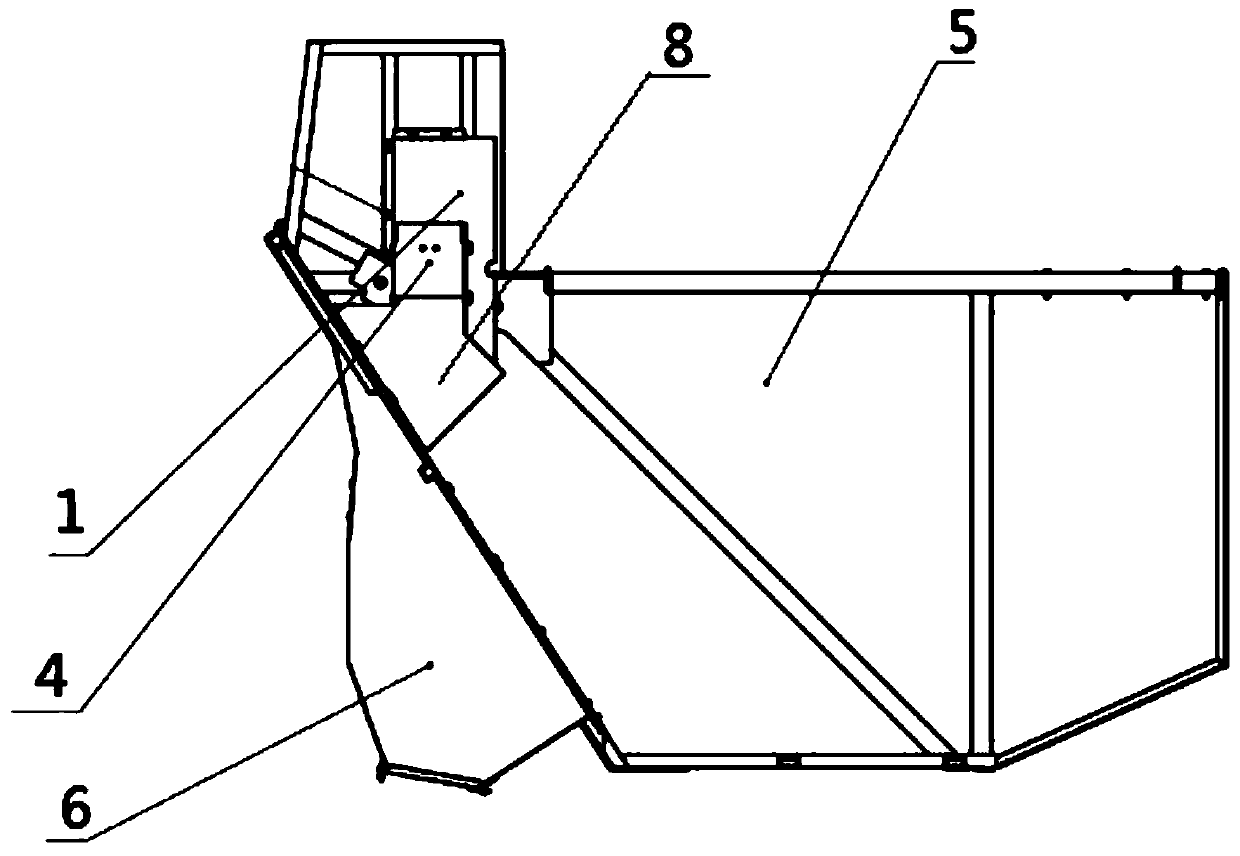

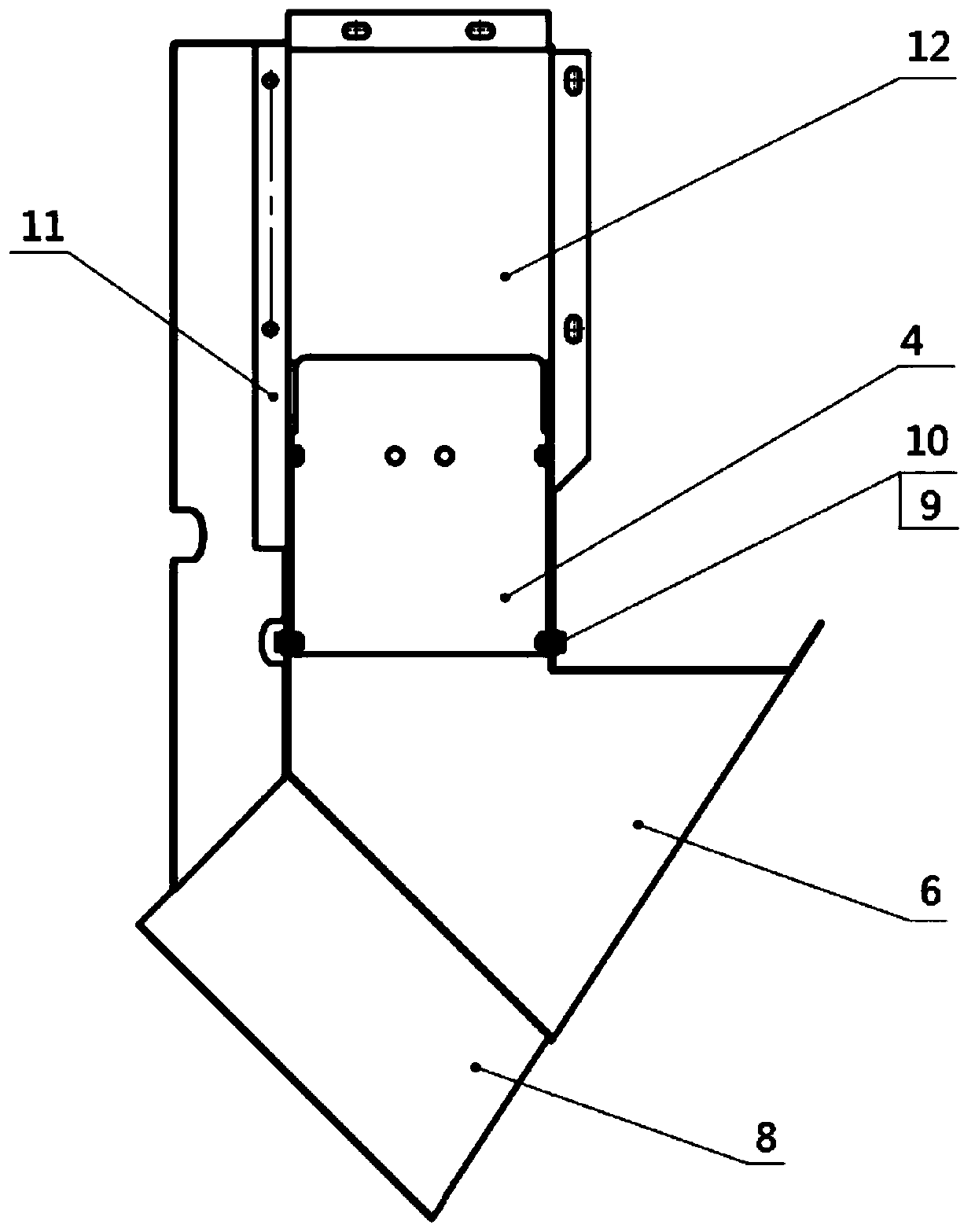

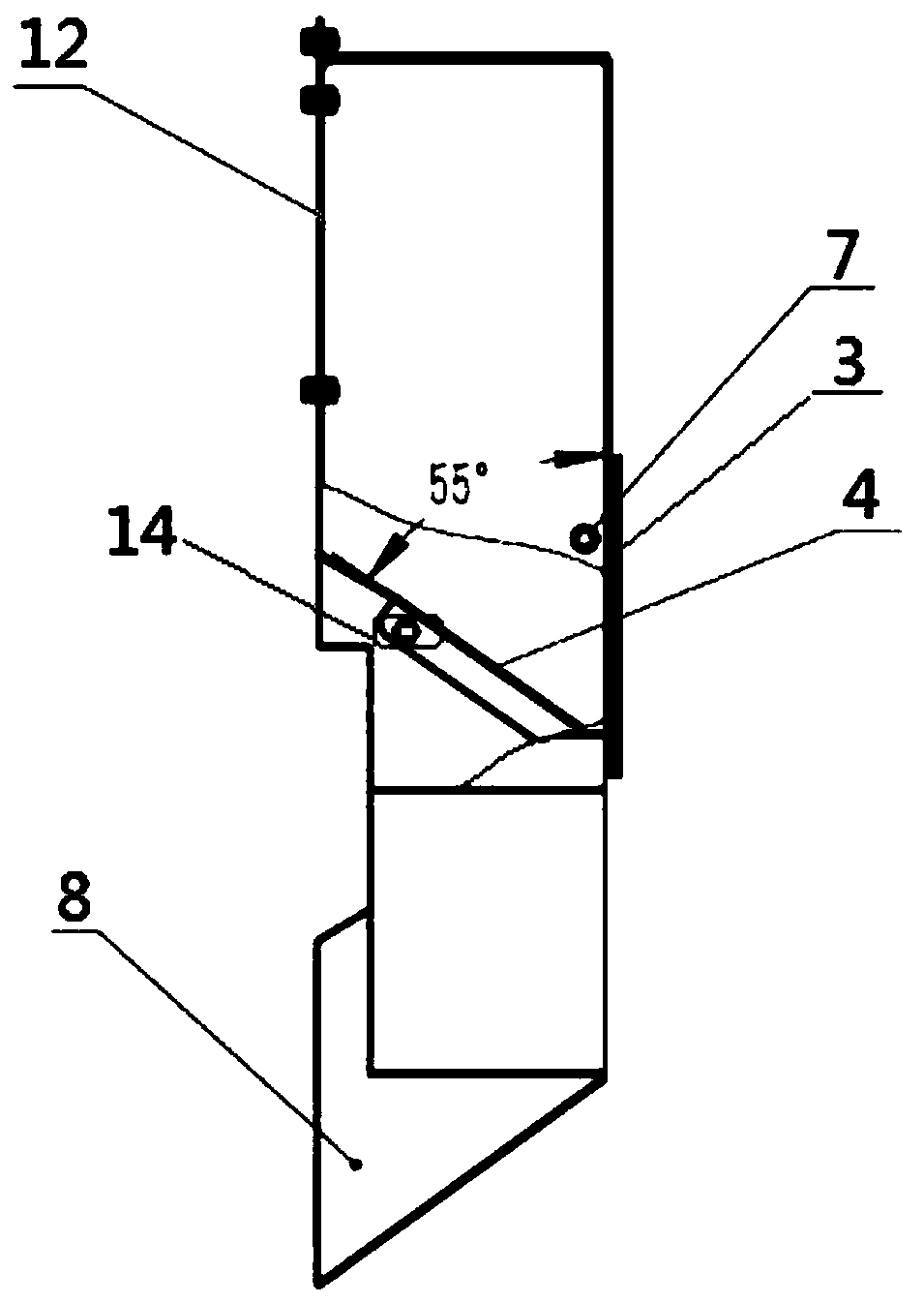

[0016] A diversion cover type granary with adjustable material path, comprising a diversion cover 1, a granary 5, a grain bin 6, a grain diversion opening 8, a flap 4, and a granary diversion opening 3; the diversion cover 1 is provided with a granary 5 The connected granary diversion port 3; the diversion hood 1 is provided with a grain diversion port 8 connected to the grain bin 6; the side wall opening of the diversion hood 1 is provided with a screw 9; the screw 9 is connected to the flap 4 and the two ends pass through The nut 10 is fixed on the side wall of the shroud 1; the flap 4 is fixed inside the shroud 1; the shaft end of the flap 4 is rotated by 55° with the screw rod 9 as the rotating shaft in the shroud 1; when the flap 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com