Assembly-type spliced bathroom bottom sheet

A prefabricated, chassis technology, used in bathtubs, showers, home appliances, etc., can solve the problems of expensive chassis molds, waste of space, inability to meet chassis molds, etc., to achieve better waterproof effect, easy installation, and improved connection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

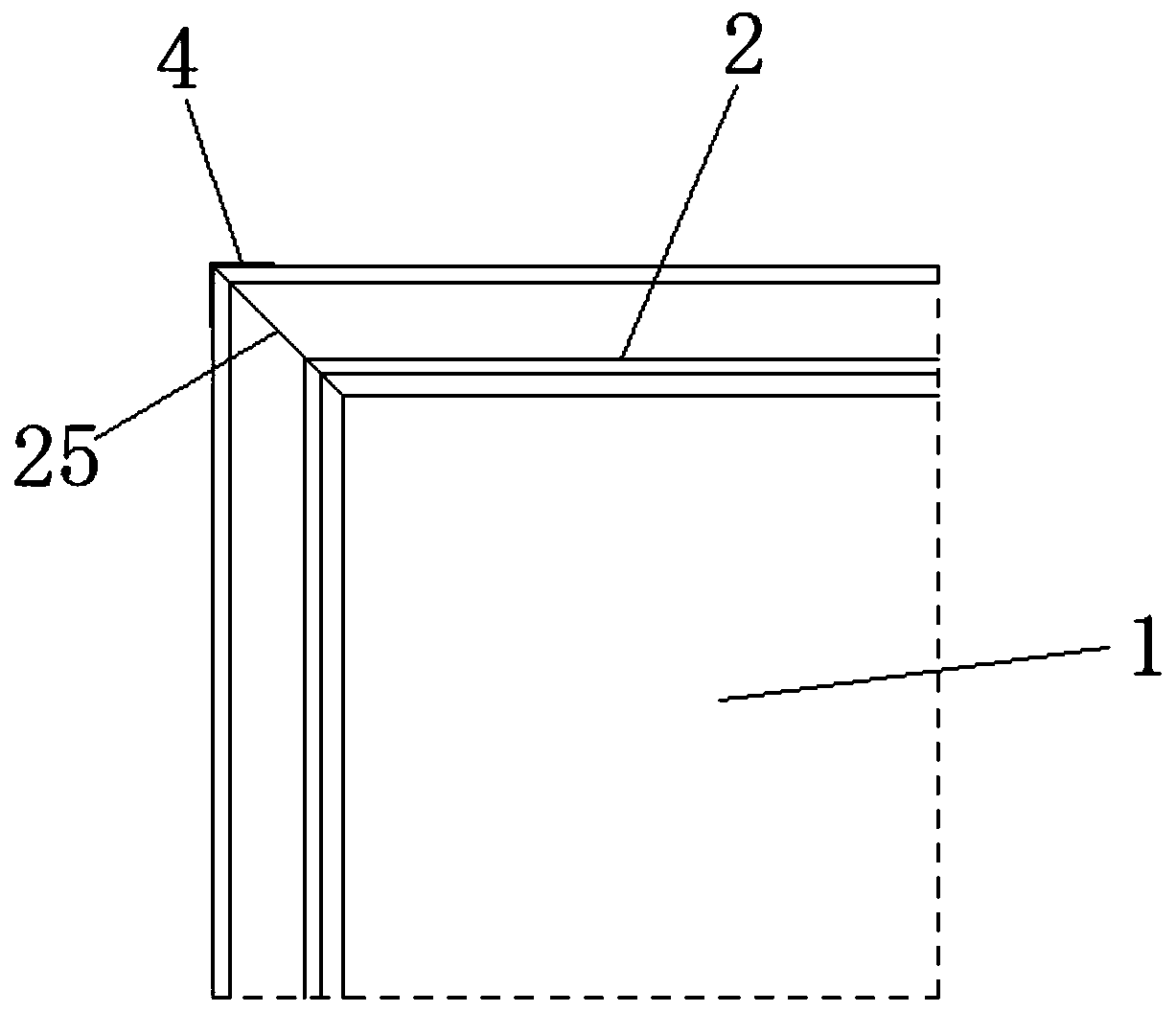

[0035] see Figure 1 to Figure 3 , the figure shows an assembled and assembled bathroom chassis provided by Embodiment 1 of the present invention, which includes: SMC chassis 1, SMC chassis 1 is square, and connecting plates 11 are arranged on its surrounding edges; aluminum alloy frame, its Surrounded by the SMC chassis 1, the aluminum alloy frame includes four spliced aluminum alloy profiles 2, the aluminum alloy profiles include a main body 21, a rib 22 arranged on the main body 21, a waterproof platform 23, a connecting groove 24, and a connecting plate 11 is plugged or hooked with the connection groove 24; the plastic seal 3 is inserted in the joint of two adjacent aluminum alloy profiles 2.

[0036] Specifically, both ends of the aluminum alloy profiles 2 are provided with 45° cutting surfaces 25 , and the two aluminum alloy profiles 2 are spliced through the cutting surfaces 25 .

[0037] An assembled and assembled bathroom chassis provided in this embodiment mainl...

Embodiment 2

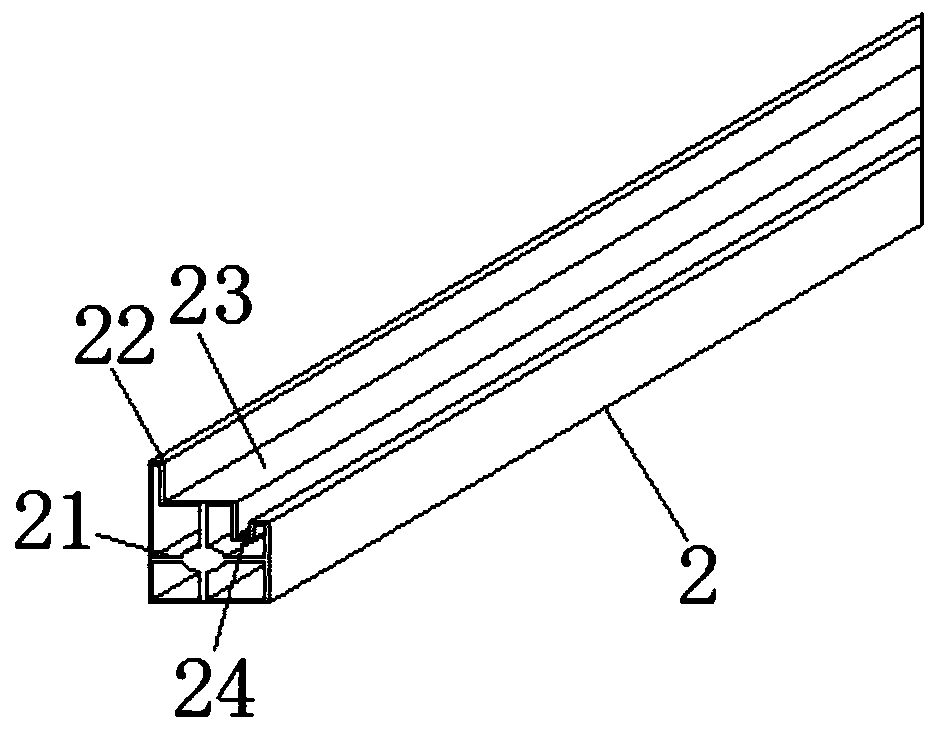

[0045] see Figure 3-4 , the figure shows an assembled and assembled bathroom chassis provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: ribs 22 , waterproof platform 23 are all arranged on the top of main body 21, rib 22 is positioned at the outside of waterproof platform 23, and the height of waterproof platform 23 is lower than rib 22; The width of rib 22, waterproof platform 23 and main body 21 is progressively set successively; The groove 24 is arranged at the bottom of the waterproof platform 23, and the connecting groove 24 and the waterproof platform 23 are parallel and arranged along the horizontal direction. With the arrangement of the above structure, the connection between the SMC chassis 1 and the aluminum alloy profile 2 can be completed by plugging the connecting plate 11 and the connecting groove 24, which is not only convenient for ...

Embodiment 3

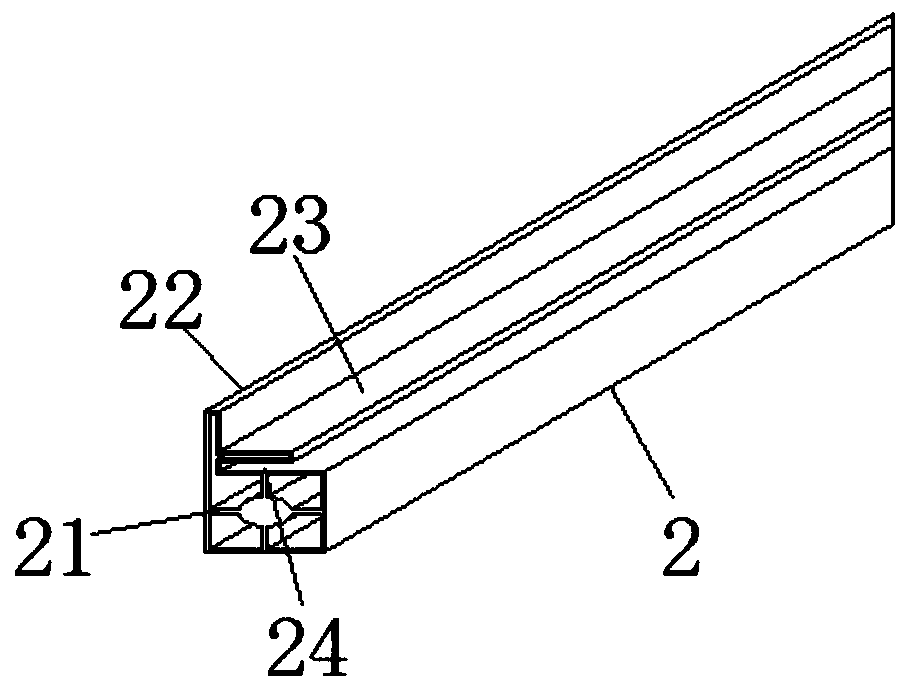

[0047] see figure 2 , Figure 5, the figure shows a prefabricated and assembled bathroom chassis provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the rest and implementation Example 2 is the same, the difference is that the connection plate 11 is inserted in the connection groove 24; the connection groove 24 is arranged on the inside of the waterproof platform 23, and is arranged along the vertical direction; the connection groove 24 and the waterproof platform 23 are perpendicular; the connection plate 11 is provided with a hook 12, and the hook 12 is articulated with the connecting groove 34. Through the setting of the above structure, the connection between the SMC chassis 1 and the aluminum alloy profile 2 can be completed by hooking the hook 12 and the connection groove 24, which is not only convenient for installation, but also has good co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com