Cloth-bag quick-disassembly-type dust removal environment-friendly equipment

A kind of environmental protection equipment, quick-release technology, applied in the direction of dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problem of cumbersome disassembly operation, achieve simple and fast disassembly and installation, simple and convenient dust discharge, and easy maintenance. replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

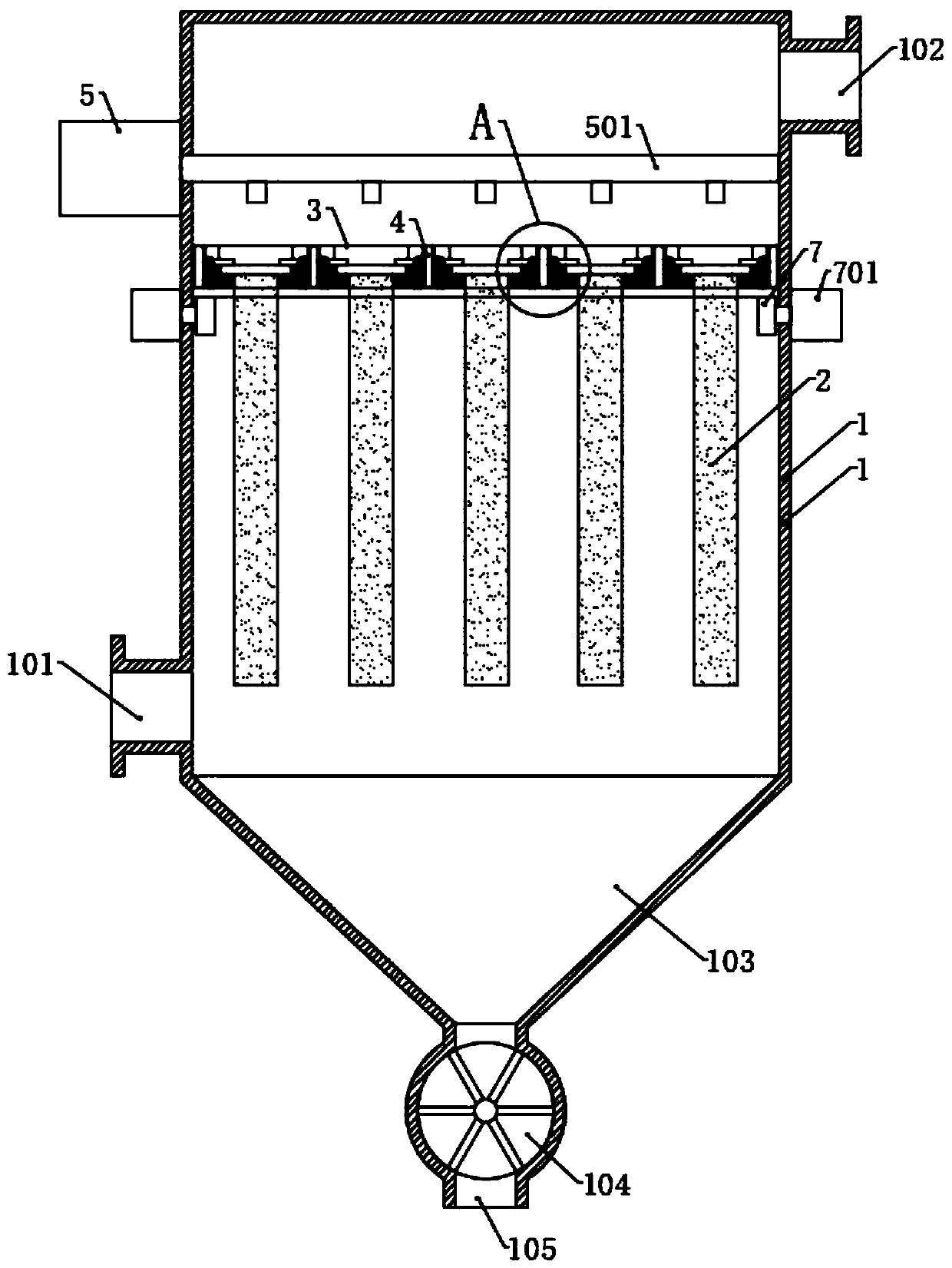

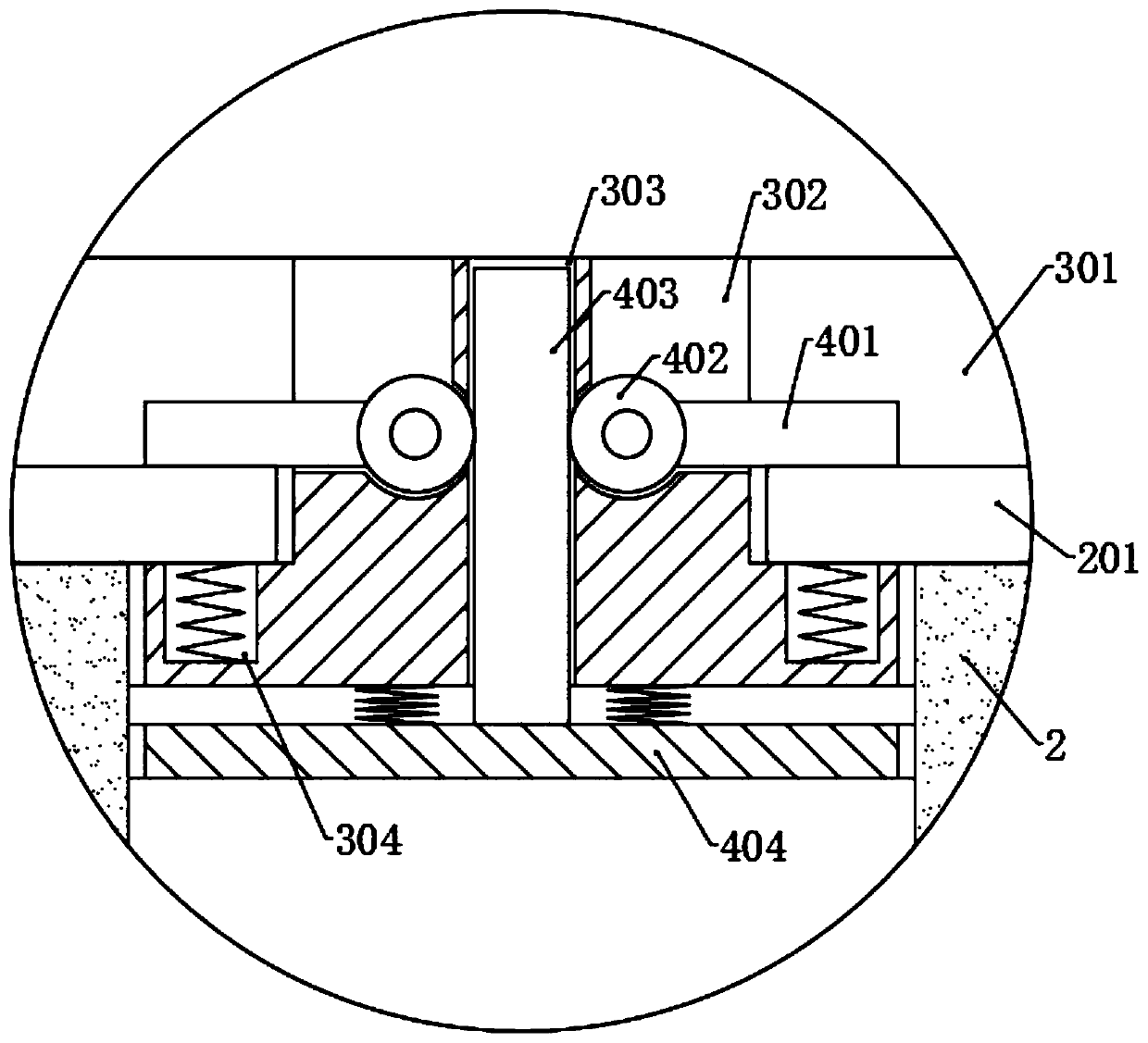

[0024] Please refer to the accompanying drawings, the present invention provides a technical solution: a bag-type quick-dismantling dust removal environmental protection equipment, including a dust removal box 1, the left bottom of the dust removal box 1 is provided with an air inlet pipe 101, and the right top is provided with an air outlet pipe 102, And the bottom end is provided with ash hopper 103, the top of dust removal box 1 is fixed with air blowing pipe 501, is evenly provided with a plurality of air blowing ports on the air blowing pipe 501, and one end of air blowing pipe 501 stretches out dust removal box 1 and is connected with air pump 5, dust removal The upper part of the inner cavity of the box 1 is fixed with a fixed plate 3, and a plurality of positioning grooves 301 are evenly arranged on the fixed plate 3, and a fixed ring 201 is arranged in the positioning groove 301, and a positioning assembly is arranged on the fixed plate 3 corresponding to the position o...

Embodiment 2

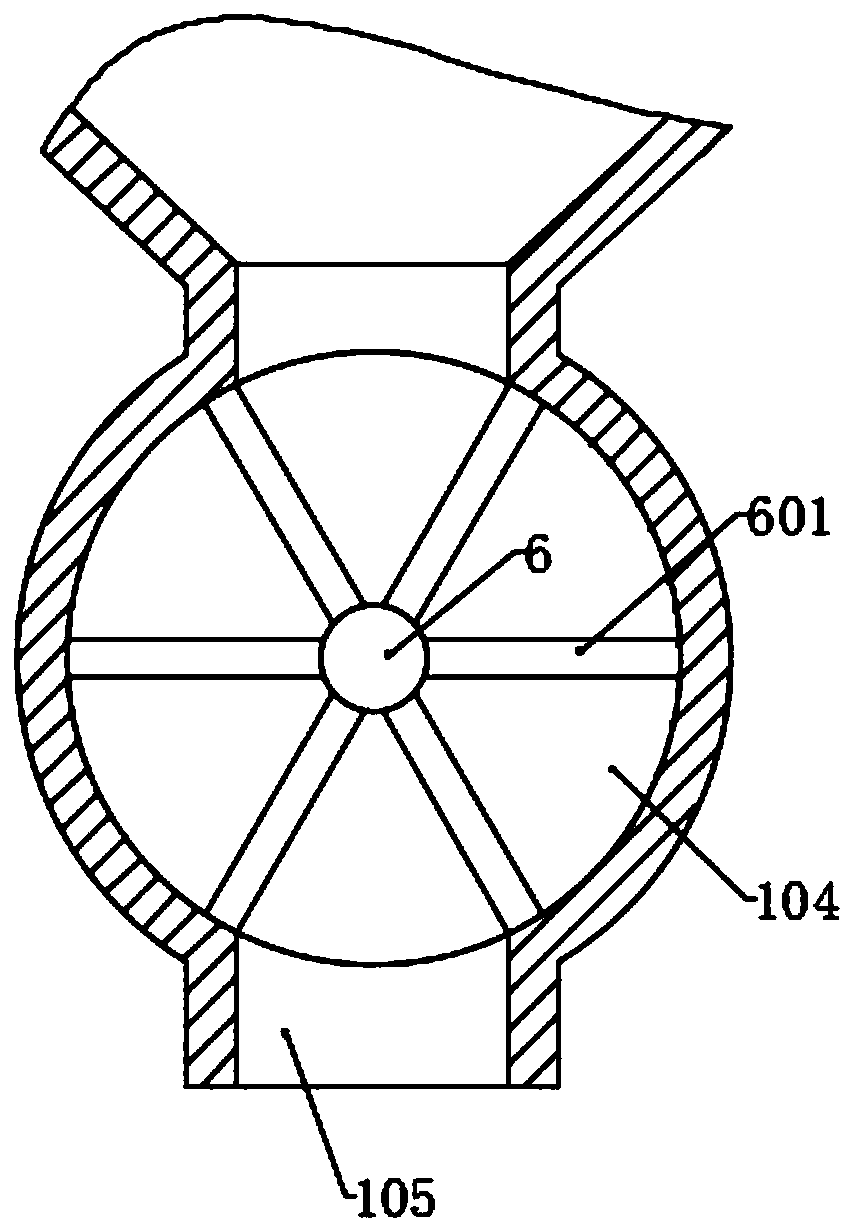

[0029] On the basis of Embodiment 1, a soot cleaning pipe 105 is fixed in the middle of the bottom surface of the ash hopper 103, and a soot cleaning assembly is arranged in the ash cleaning pipe 105. The ash cavity 104 is a cylindrical cavity arranged horizontally, and the center of the circle is rotatably connected with a rotating shaft 6 on which a plurality of rotating plates 601 are evenly fixed along the circumferential direction, and one end of the rotating shaft 6 is connected with a second motor.

[0030] When the dust deposited on the bottom of the ash hopper 103 needs to be cleared out, the rotating shaft 6 drives a plurality of rotating plates 601 to rotate intermittently through the second motor, and the dust enters between the two rotating plates 601, and along with the rotating shaft 6 and the rotating plates 601 rotates, gradually moves to the bottom of the dust cleaning chamber 104, and is discharged by the dust cleaning pipe 105, the dust discharge is simple a...

Embodiment 3

[0032]On the basis of Embodiment 1, the bottom surface of the positioning groove 301 is uniformly provided with a plurality of spring grooves 304 along the circumferential direction, and springs are arranged in the spring grooves 304, and the top of the spring contacts the bottom surface of the fixed ring 201. When the positioning block 401 rotates And when disengaging from the fixed ring 201, the fixed ring 201 moves up under the action of the spring, which is convenient for taking out the fixed ring 201 and the dust bag 2.

[0033] The bottom surface of the positioning groove 301 is provided with a gasket, and the bottom surface of the fixed ring 201 is in contact with the gasket, so that the fixed ring 201 is pressed tightly on the gasket on the bottom surface of the positioning groove 301 under the action of the positioning block 401, so as to improve the sealing performance and make the The upper space of the fixed plate 3 is separated from the lower space to keep the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com